Automatic connecting line measurement method and automatic connecting line measurement device

A technology of measuring device and measuring method, which is applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of unsuitable for large-scale production line measurement, long measurement time, low measurement efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

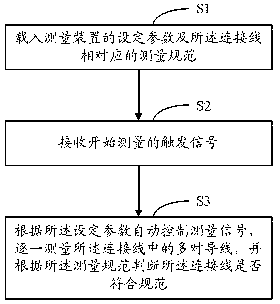

[0042] Such as figure 1 As shown, in an embodiment of the present invention, the automatic measurement method for connecting wires includes:

[0043] S1. Load the setting parameters of the measurement device and the measurement specifications corresponding to the connection line; preferably, the setting parameters of the measurement device can instruct the measurement device to measure the connection line according to a preset procedure , such as Impedance, Intra-Pair Skew, Insertion Loss, Return Loss, Near-End Crosstalk, etc.; the measurement specification may be The standard coefficients required b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com