Full-automatic optical precision measurement equipment

A technology of optical precision and measuring equipment, which is applied in sorting and other directions, and can solve the problems of precise measurement of difficult types, high labor intensity of workers, and poor measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

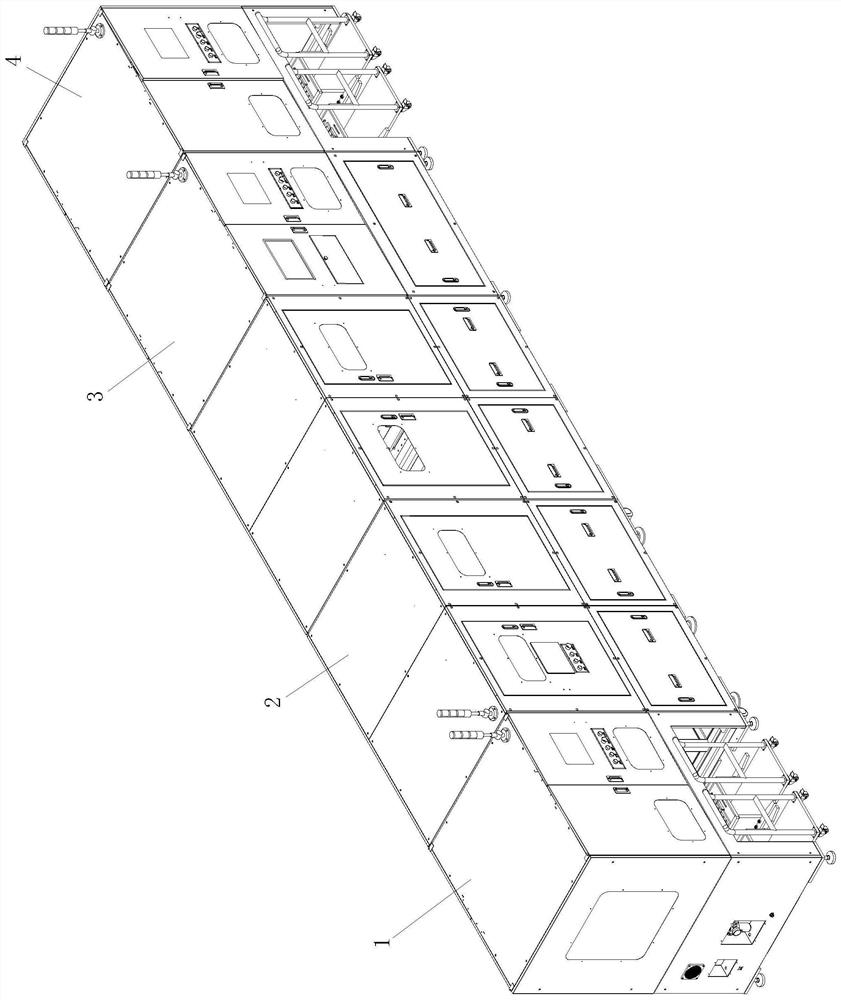

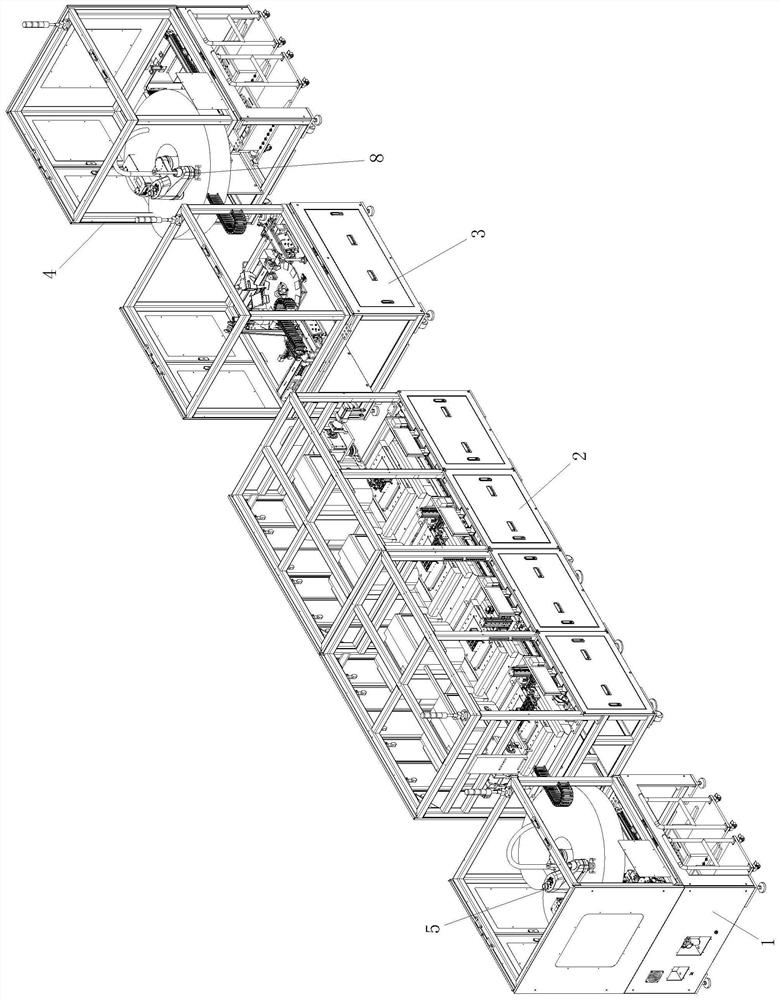

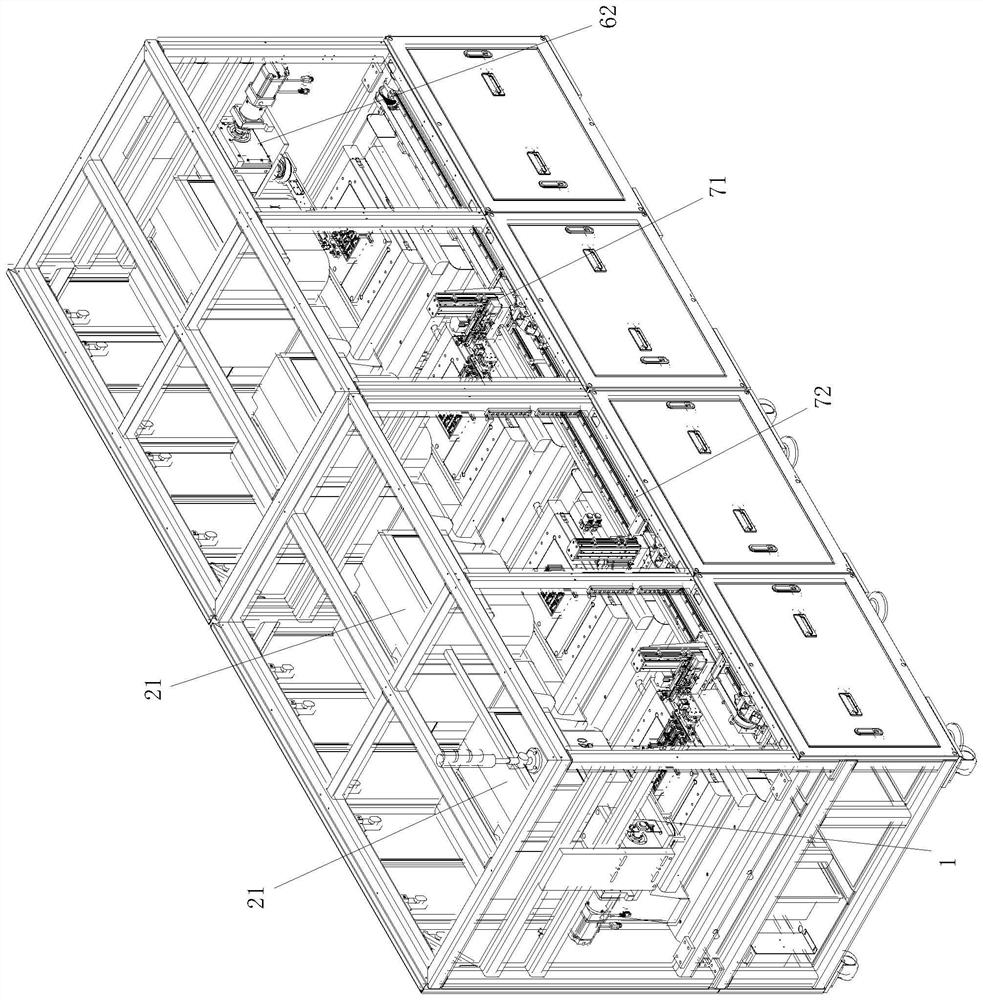

[0027] In this example, refer to Figure 1-Figure 9 , the fully automatic optical precision measuring equipment includes a test device 2 and a turntable test mechanism 3, the test device 2 is provided with a one-button measuring instrument 21; the turntable test mechanism 3 is arranged on the back station of the test device 2, and the turntable test Mechanism 3 is provided with a turntable test platform 31 for measuring the through-hole size of the workpiece (product), the size of front and back blind holes, flatness and other parameters; On the side of the feeding mechanism 1 close to the testing device 2, there is a feeding flexible manipulator 5 for swinging the workpiece;

[0028] The head end of the testing device 2 is provided with a feeding manipulator 61 for transferring the finished workpiece to the one-button measuring instrument 21. The discharging manipulator 62 on the turntable testing mechanism 3. Use the feeding flexible manipulator 5 to take out the products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com