Terminal plugging tool for automobile harness connectors

A technology for automotive wiring harnesses and connectors, which is applied in the assembly/disassembly of contacts, circuit/collector parts, connections, etc. It can solve the problems of missed terminal pull-back operation, different terminals, and broken terminals, etc. Hidden dangers of failure, reduction of failure rate, and improvement of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

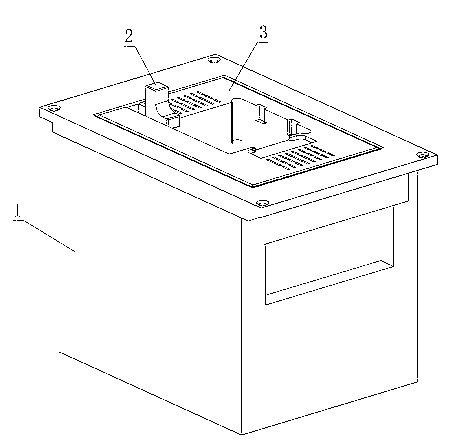

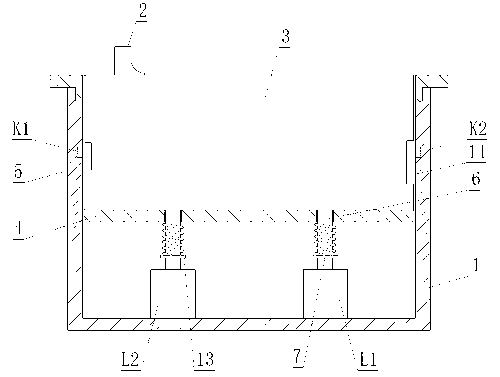

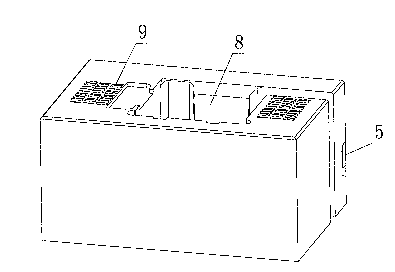

[0023] See Figure 1~ Figure 5 , the present invention includes a trough housing 1, a counterweight module 3, a sheath locking device (including a locking arm 2 and a return spring 10), a guide rod 6, a buffer spring 7, two displacement sensors, two proximity switches and Monitoring circuit, the monitoring circuit mainly includes CPU, keyboard KB, liquid crystal display LCD, pull-back indicator light D and alarm buzzer FM.

[0024] The counterweight module 3 is provided with a sheath groove 8, and the shape of the sheath groove 8 is completely consistent with the plastic sheath, so that the plastic sheath can only be placed in a set direction, and it cannot be inserted into the sheath groove 8 when it is placed in the wrong direction, thereby It effectively prevents terminal insertion errors caused by reverse insertion of the sheath.

[0025] When the terminal is pulled back, the sheath locking device can prevent the plastic sheath from coming out of the counterweight module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com