Three-linkage synthesis core-pulling device of injection mould

A technology for injection molds and core-pulling devices, which is applied in the field of three-link synthetic core-pulling devices for injection molds, and can solve problems such as prone to failure, increased mold costs, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

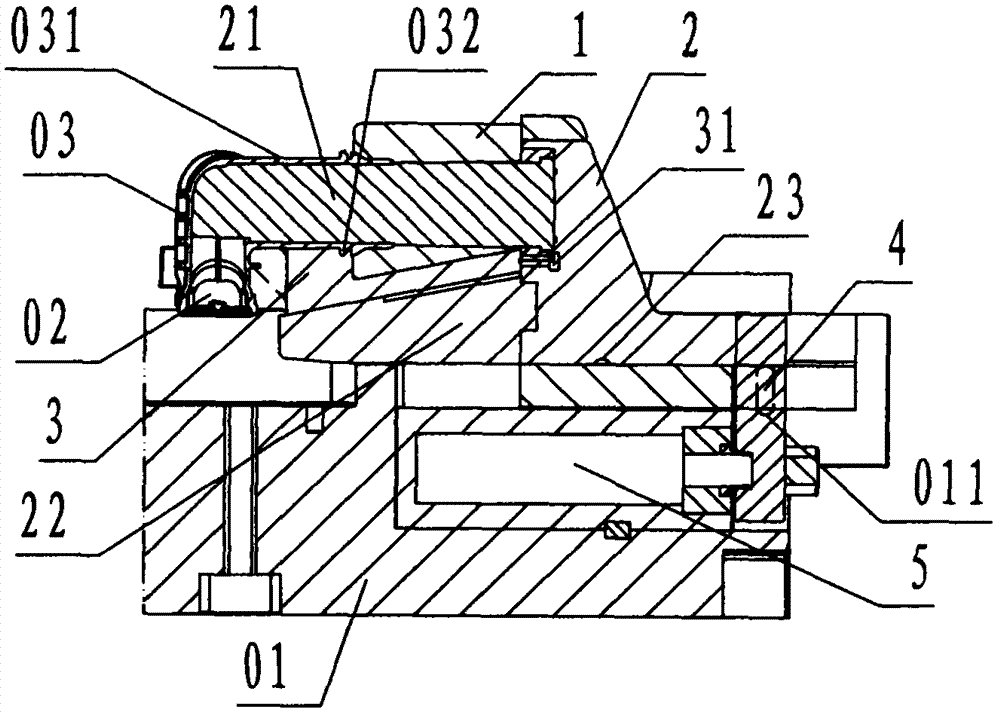

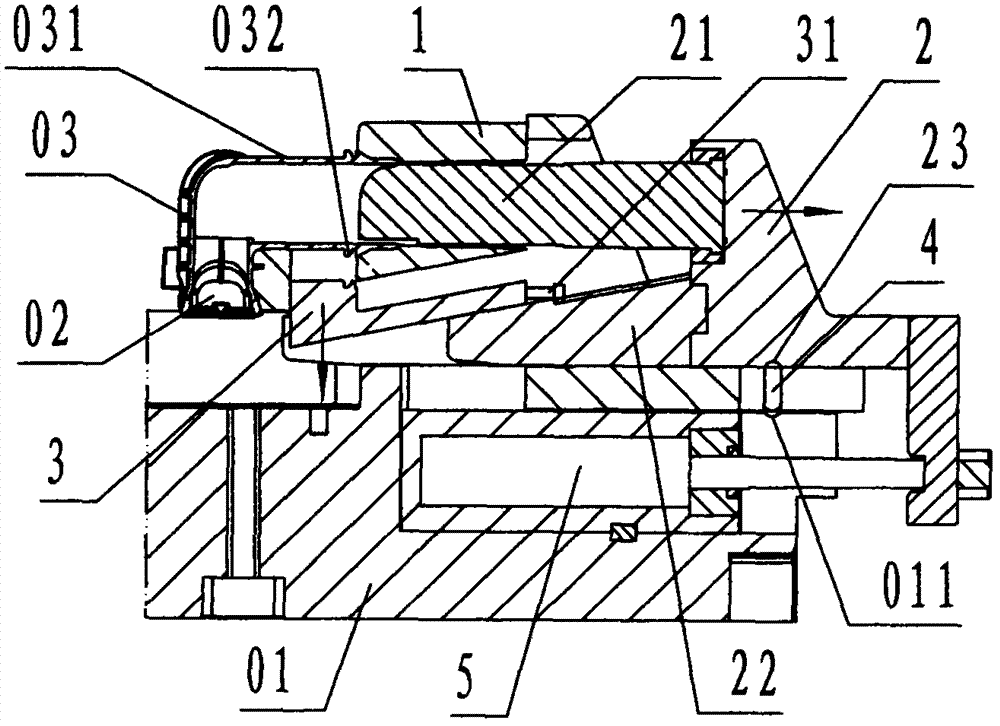

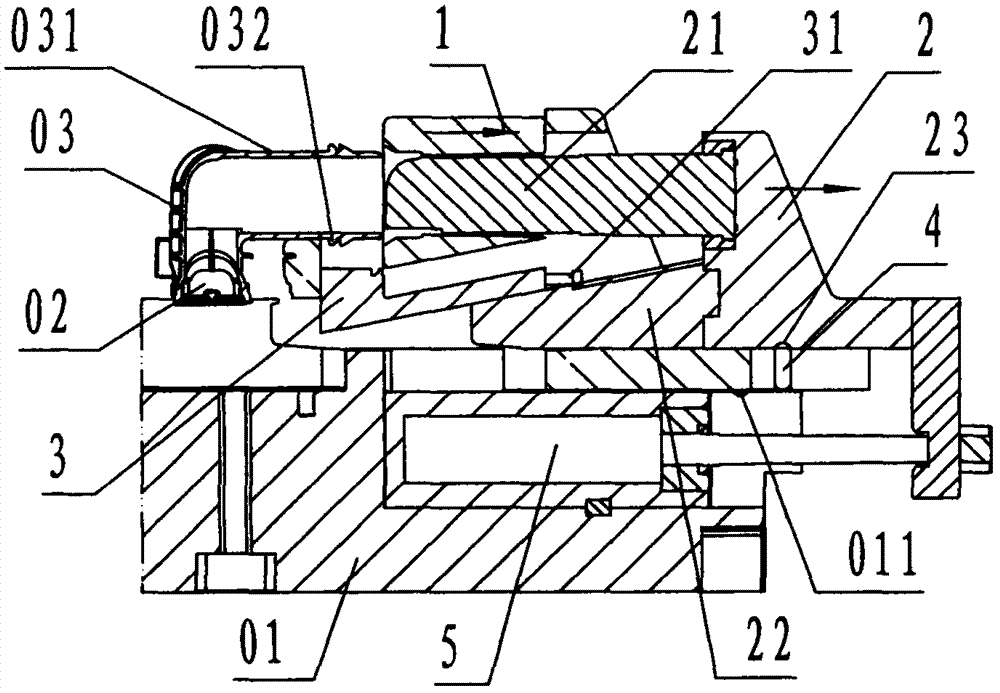

[0021] refer to Figure 1 to Figure 4 , a three-link synthetic core-pulling device for an injection mold of the present invention, comprising a large slider 1, a small slider 2, a lower slider 3, a clutch pin 4, and an oil cylinder 5, wherein: the large slider 1 is block-shaped Steel components, the middle part of the large slider 1 is provided with a slot facing downwards, and the through groove connected in the left and right direction is called a small chute, and the upper part of the left side of the large slider 1 is provided with the outer wall of the pipe interface 031 of the product 03 The profile corresponding to the shape is called the lumen, and the front and back of the lower part of the left side of the large slider 1 is also provided with a profile that matches the undercut structure of the product 03, which is called the horizontal buckle profile; the bottom of the large slider 1 The slide rail with left and right directions is called a large slide rail, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com