Power Module Fixing Mechanism

A technology of power supply module and fixing mechanism, which is applied to the circuit layout of the supporting structure, the components of the casing/cabinet/drawer, elastic/clamping device, etc., which can solve the problems of increased transportation costs, waste of space, and unfavorable users operation and other issues to achieve the effect of simplifying removal or insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The preferred embodiments of the present invention are described hereby in conjunction with the accompanying drawings.

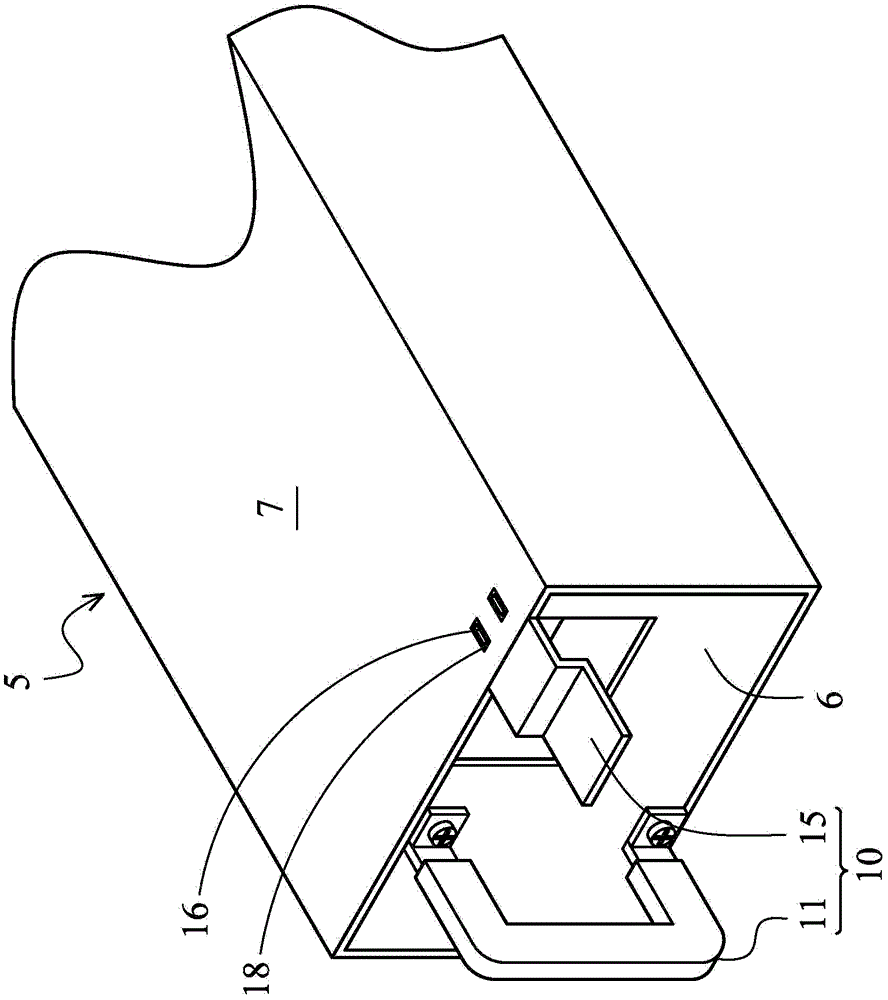

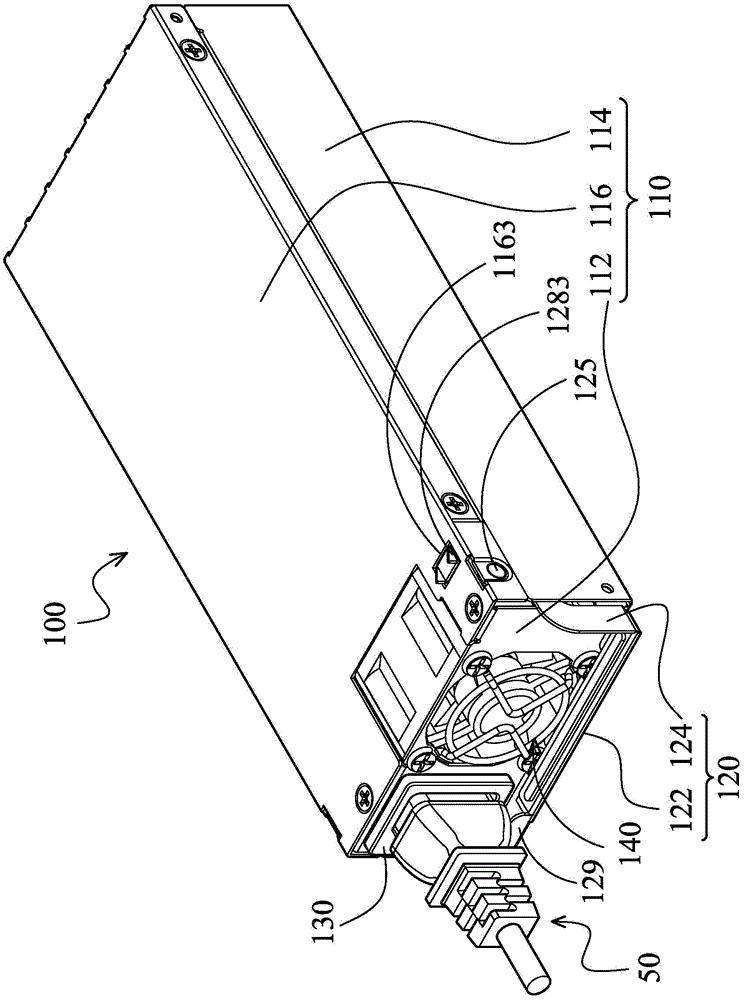

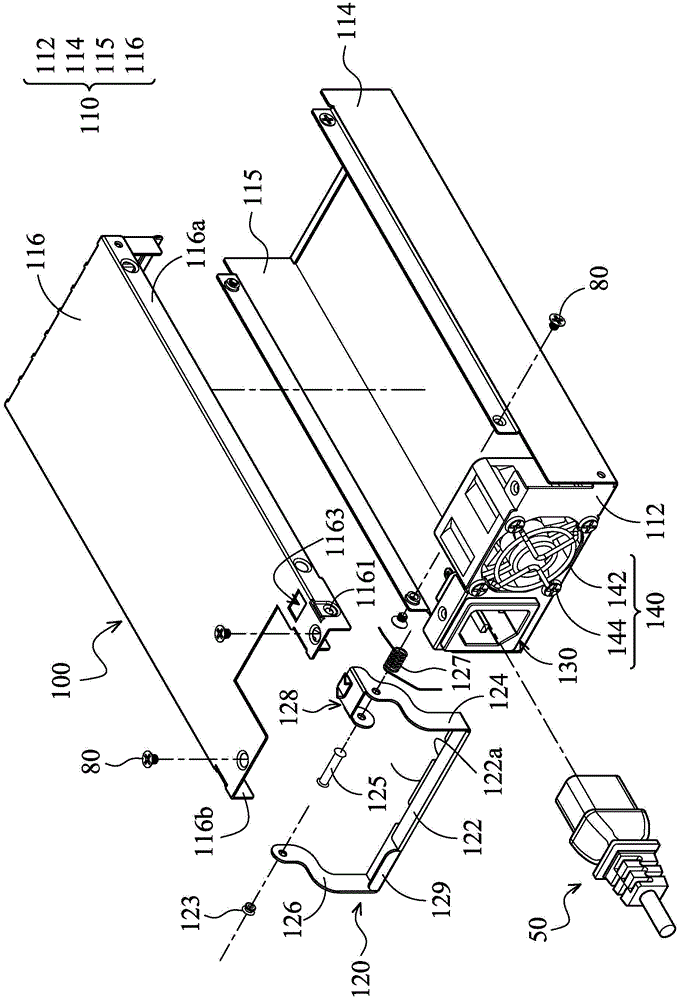

[0061] see figure 2 and image 3 , figure 2 A schematic diagram showing that the power module fixing mechanism 100 of the present invention is connected to a plug 50, wherein the operating lever 120 is located at a first position; image 3 In , the electronic components inside the power module body 110 are omitted from drawing, and are indicated here in advance.

[0062] The power module fixing mechanism 100 of the present invention includes a power module body 110 , an operating lever 120 , a socket 130 and a fan component 140 . In a specific embodiment, the power module body 110 is a rectangular structure, including a front cover 112 , two side covers 114 and 115 and a top cover 116 . The two side covers 114 and 115 are respectively adjacent to the left and right sides of the front cover 112 and opposite to each other. The upper cover 116 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com