Ridging device for planting strawberries

A technology for forming strawberries and ridges, applied in the fields of application, agricultural machinery and tools, plows, etc., can solve the problems of not throwing soil on the upper part of the ridge, and ridges have no reference significance, and meet the requirements of large-scale ridges, Guarantee the effect of stable ridge base and high ridge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

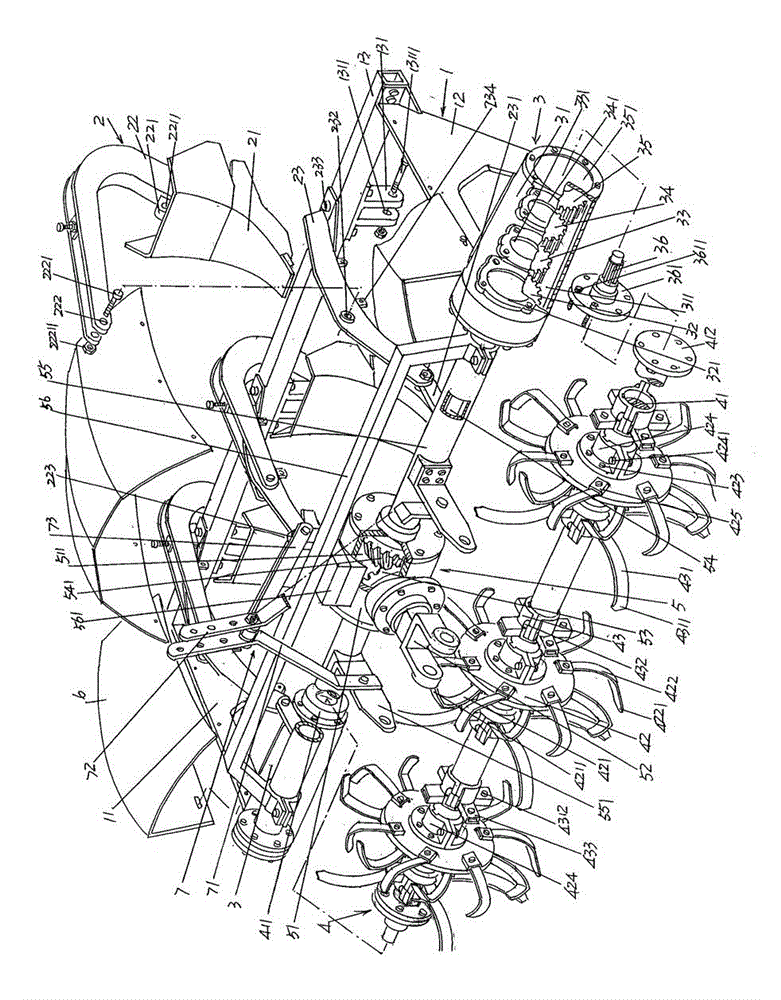

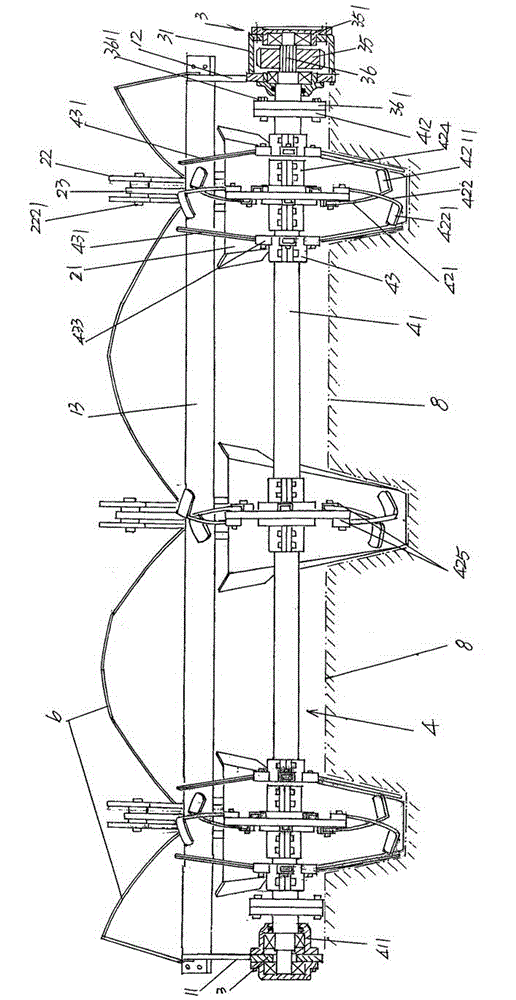

[0020] See figure 1 and figure 2 , a frame 1 is given, which is composed of a pair of first and second wall panels 11, 12 which are arranged facing each other and whose geometric shape is generally triangular, and a beam 13. One end of the beam 13 is shown in Fig. The left end showing the position state is fixed with the first wallboard 11, and the other end of the beam 13 is fixed with the second wallboard 12 which is the right end of the state shown in the figure.

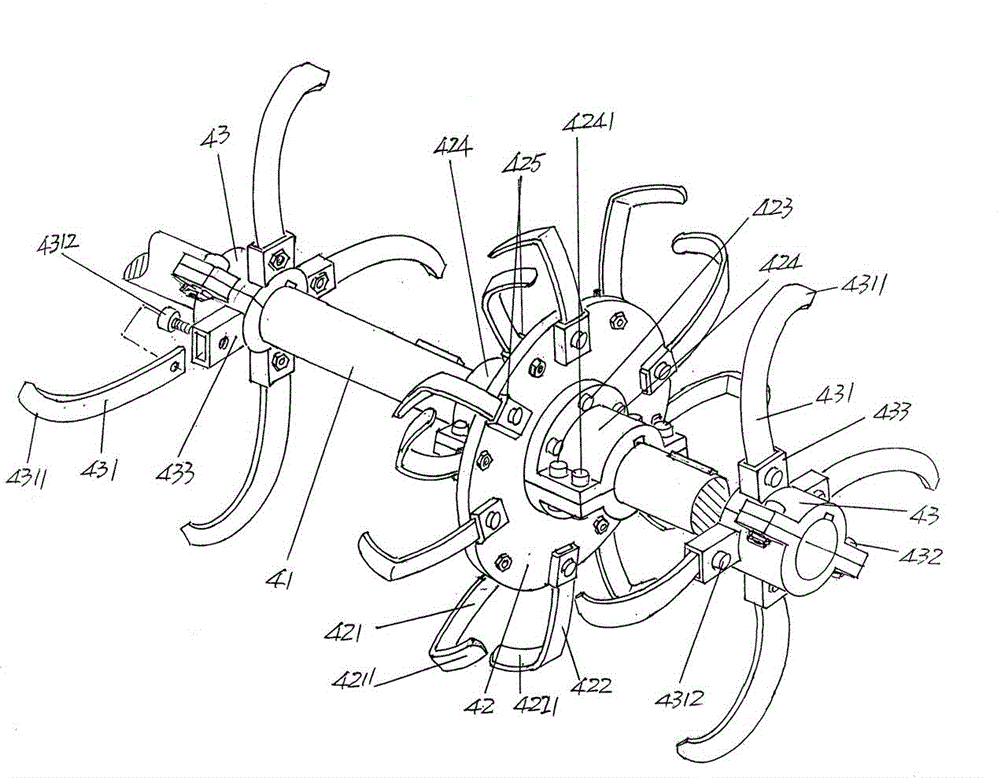

[0021] A group of furrow mechanism 2 is provided, and in the present embodiment, the quantity of a group of furrow mechanism 2 is three, thus can loosen soil to the soil of three furrows at one time, and three furrows can form two furrow platforms, of course one The quantity of group furrow mechanism 2 is not absolutely limited to three, can increase or decrease according to specific conditions, each furrow mechanism 2 comprises plowshare 21, plowshare frame 22 and support plate 23, plowshare 21 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com