Automatic sorting and allocation method of cigarettes

A distribution method and technology of cigarettes, applied in the fields of application, tobacco, and paper cigarettes, etc., can solve problems such as the impact of sorting efficiency, large differences, and fewer flues, so as to improve the utilization rate of sorting flues, reduce space resources, and replenish The effect of shortening the cargo path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

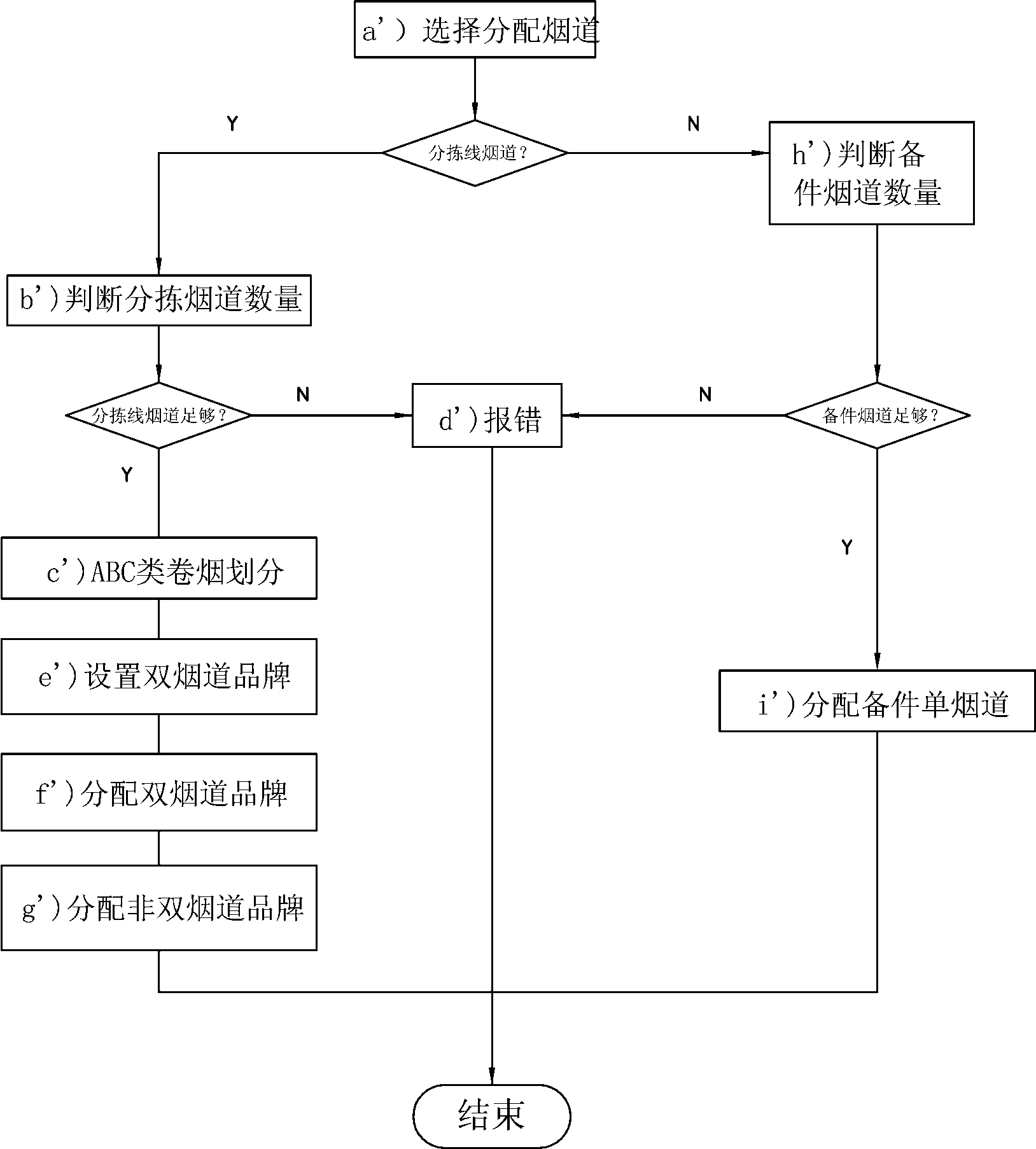

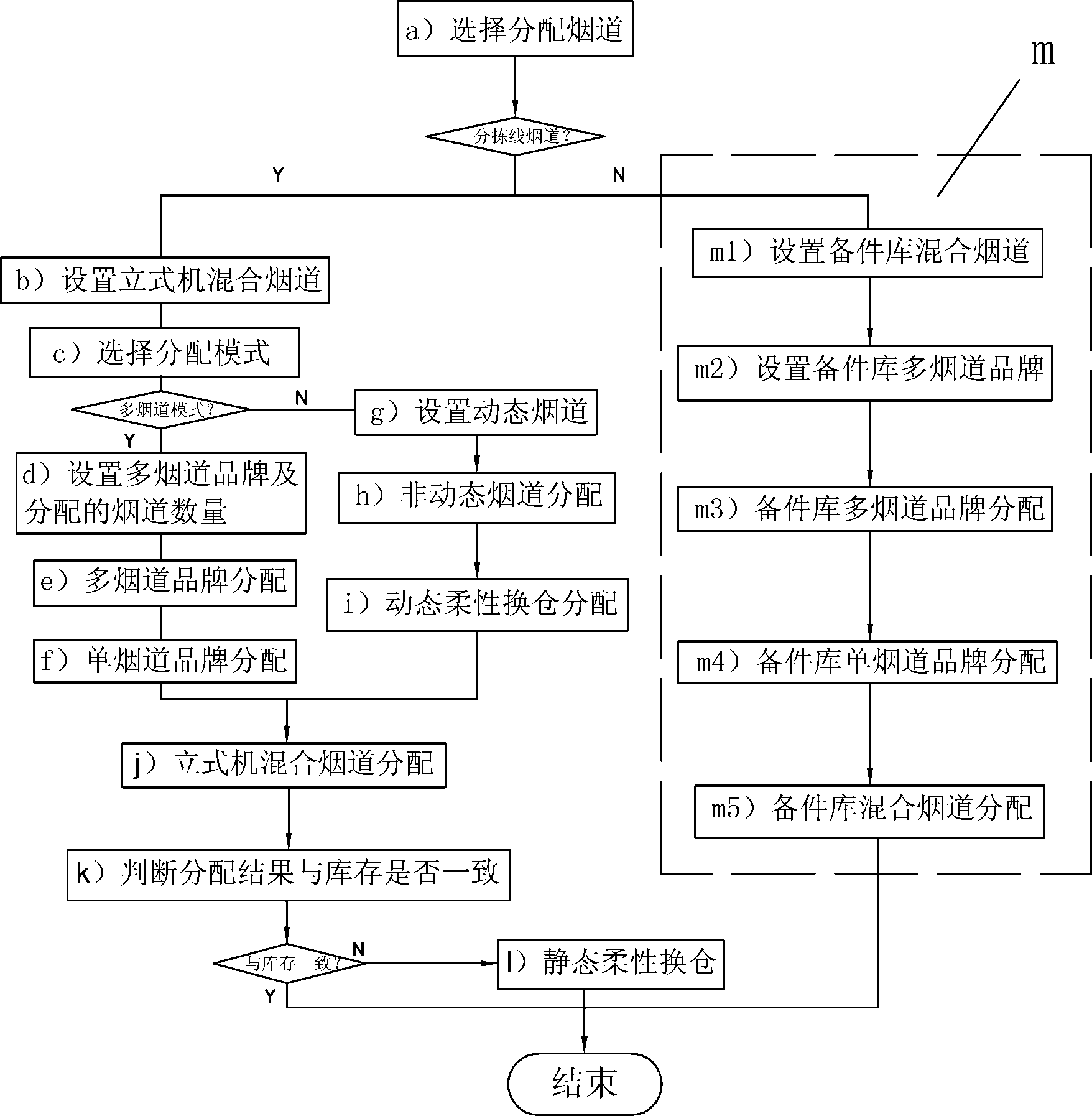

[0041] refer to figure 2 , an automatic picking and distributing method for cigarettes, comprising the following steps:

[0042] a) Select the distribution flue: choose whether to distribute the sorting line flue or the spare parts warehouse flue, if it is the sorting line flue, execute step a, otherwise execute m step;

[0043]b) Setting up vertical machine mixing ducts: set one or more vertical machine flues as vertical machine mixing ducts for dispensing multiple brands of cigarettes;

[0044] c) Select distribution mode: choose multi-flue mode or dynamic flue mode, if it is multi-flue distribution, execute step d, otherwise execute g step;

[0045] d) Set up multi-flue brands and the number of flues to be allocated: set the brands that need to be allocated with multi-flues and the number of flues to be allocated. The sales of general brands account for more than 25% of the total sales and allocate 6 flues, 20%-25% 4-6 flues are allocated, 15%-20% are allocated 3-4 flues...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com