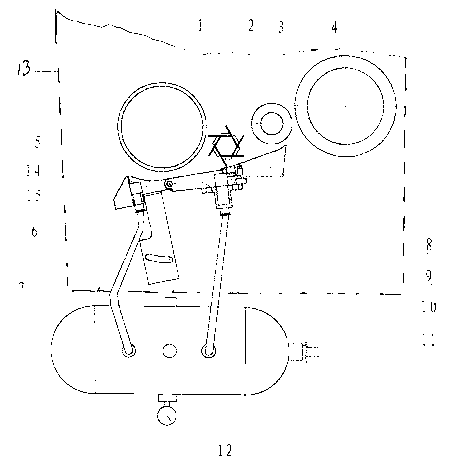

Shredded tobacco feeding device of cigarette rolling machine

A technology for a supply device and a cigarette machine, which is applied in the fields of tobacco, paper cigarette manufacturing, and application, can solve the problems of the influence of the uniformity of cut tobacco, the variation of the weight of a single cigarette, and the large number of deviations in the weight of a single cigarette, so as to reduce the number of single cigarettes. The effect of weight scale deviation, reducing residual smoke, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention is an improvement to the prior art. It includes a wallboard 13, a guide plate 10 is installed in the middle of the wallboards on both sides, and an air hole is installed with a shaft 12 on one side of the guide plate. Plate 5, a front sealing plate 14 is installed on the outside of the air hole plate, a base plate 8 is installed on the other side of the guide plate, an air hole bar 9 is installed between the base plate and the guide plate, and the upper wall between the guide plate and the front sealing plate A thread throwing roller 1 with a clearance fit is installed on the board, and a fan reel 2 is installed with a clearance fit between the wallboard behind the thread throwing roller and the air hole bar, and a clearance fit is installed between the wallboard behind the fan reel and the bottom plate A wire flicking reel 3 is installed, and a thick hook cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap