Permanent magnetic expansion cylinder magnetic extractor

A technology of permanent magnet drum and magnetic separator, applied in the field of magnetic separator, can solve problems such as energy consumption, and achieve the effects of low cost, simplified structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

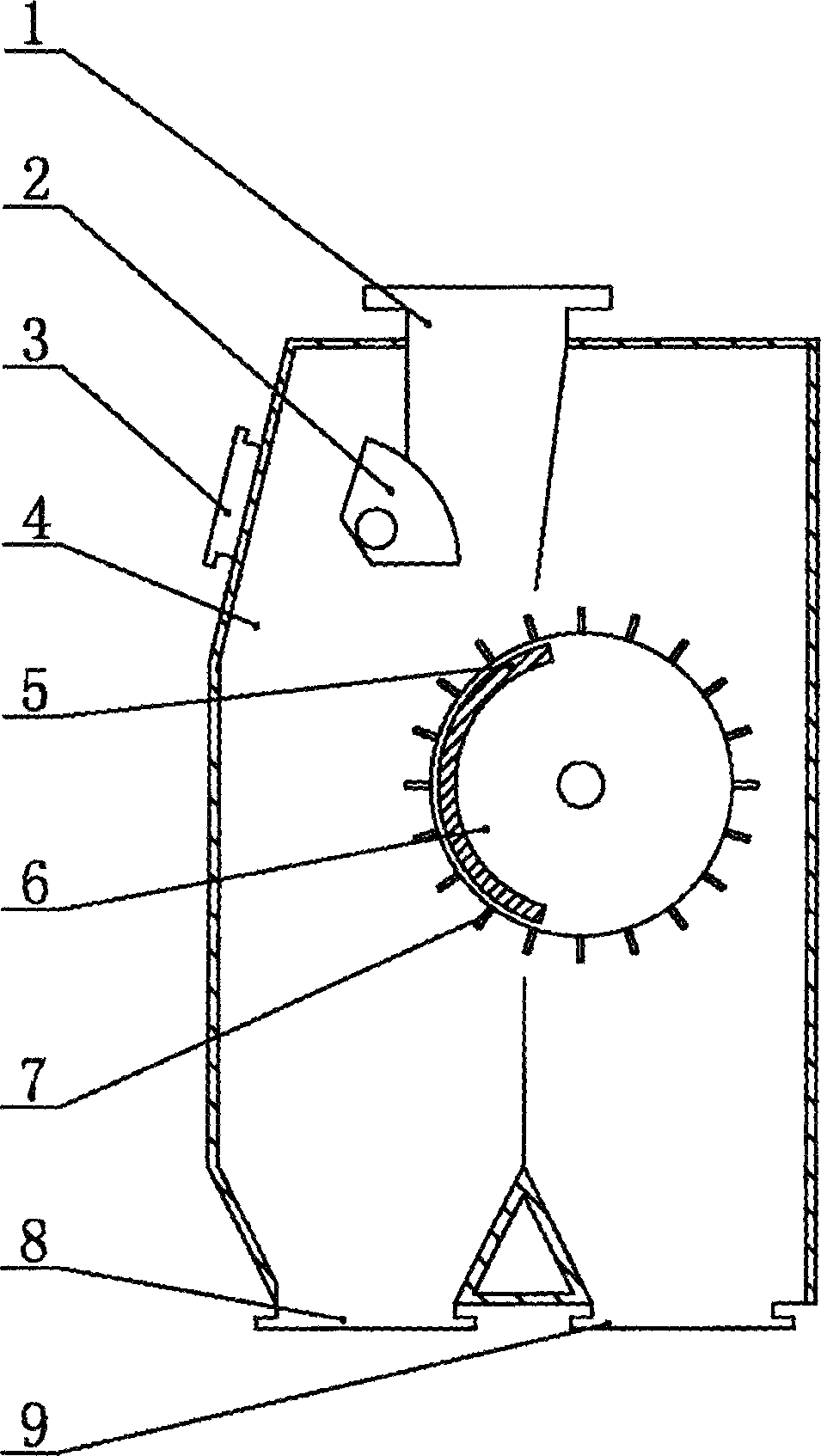

[0009] like figure 1 A kind of permanent magnet drum magnetic separator shown, comprises bin body 4, is provided with feed inlet 1 above bin body 4, is provided with discharge outlet 8 below bin body 4, and the bottom of feed inlet 1 in bin body 4 passes through A roller 6 is installed on the bearing, and a fixed magnetic group 5 is arranged inside the roller 6, and the fixed magnetic group 5 is arranged in a fan shape, an air suction port 3 is arranged above the bin body 4, and a miscellaneous discharge port 9 is arranged under the bin body 4, and the feeding Port 1 is also provided with a leveling door 2, and the outer surface of the drum 6 is provided with a number of retaining strips 7, which are evenly arranged on the outer surface of the drum 6 and can rotate together with the drum 6.

[0010] When the present invention works, the material with magnetic impurities enters the bin body 4 from the feed port 1, and when the material falls into the surface of the drum 6, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com