Anti-scrape rolling guide groove

An anti-scratch and guide groove technology, applied in the direction of guiding/positioning/alignment devices, etc., can solve the problems of rapid wear of guide grooves, high material consumption, frequent replacement, etc., and achieve high stability of rolled pieces, remarkable effect, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

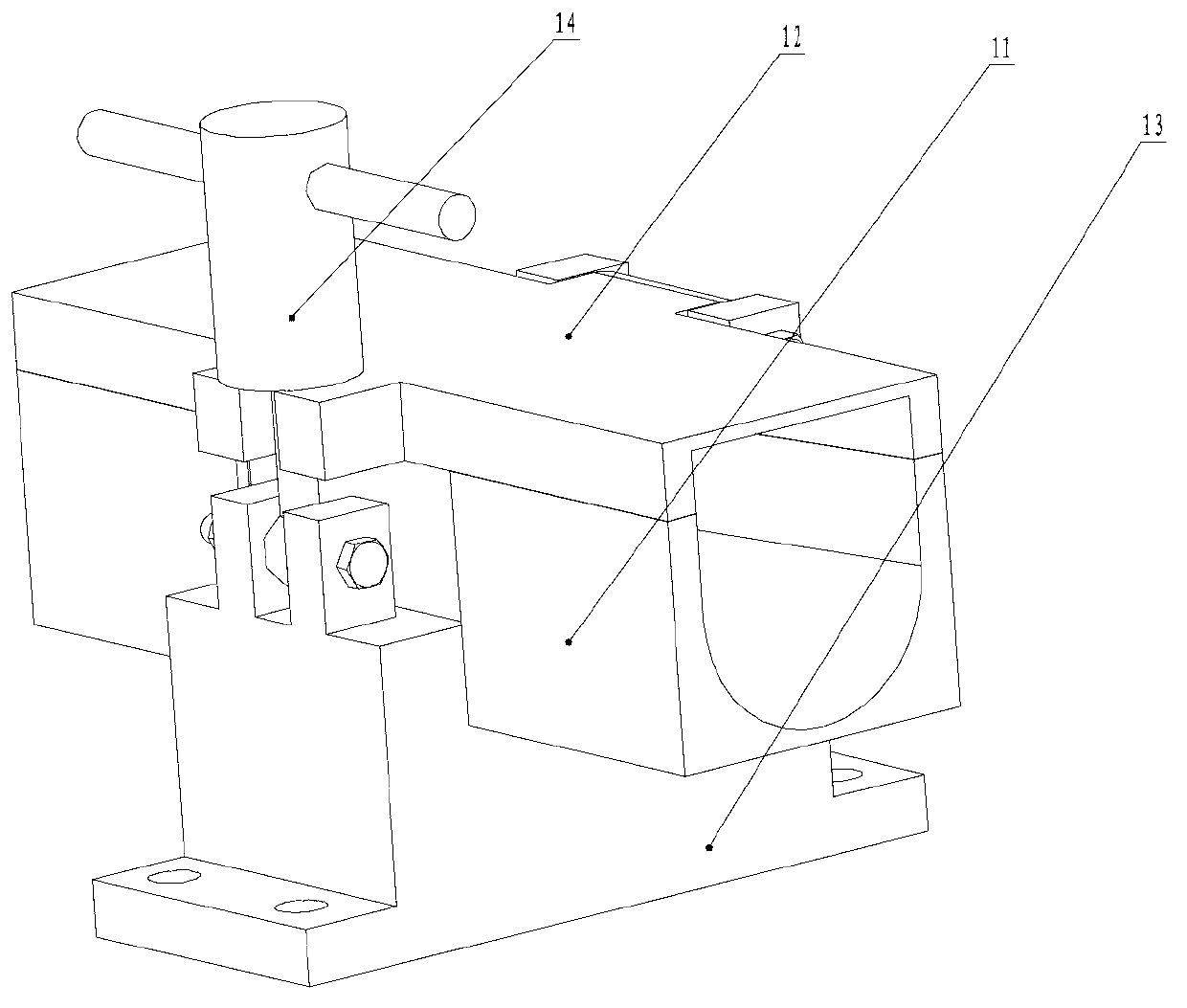

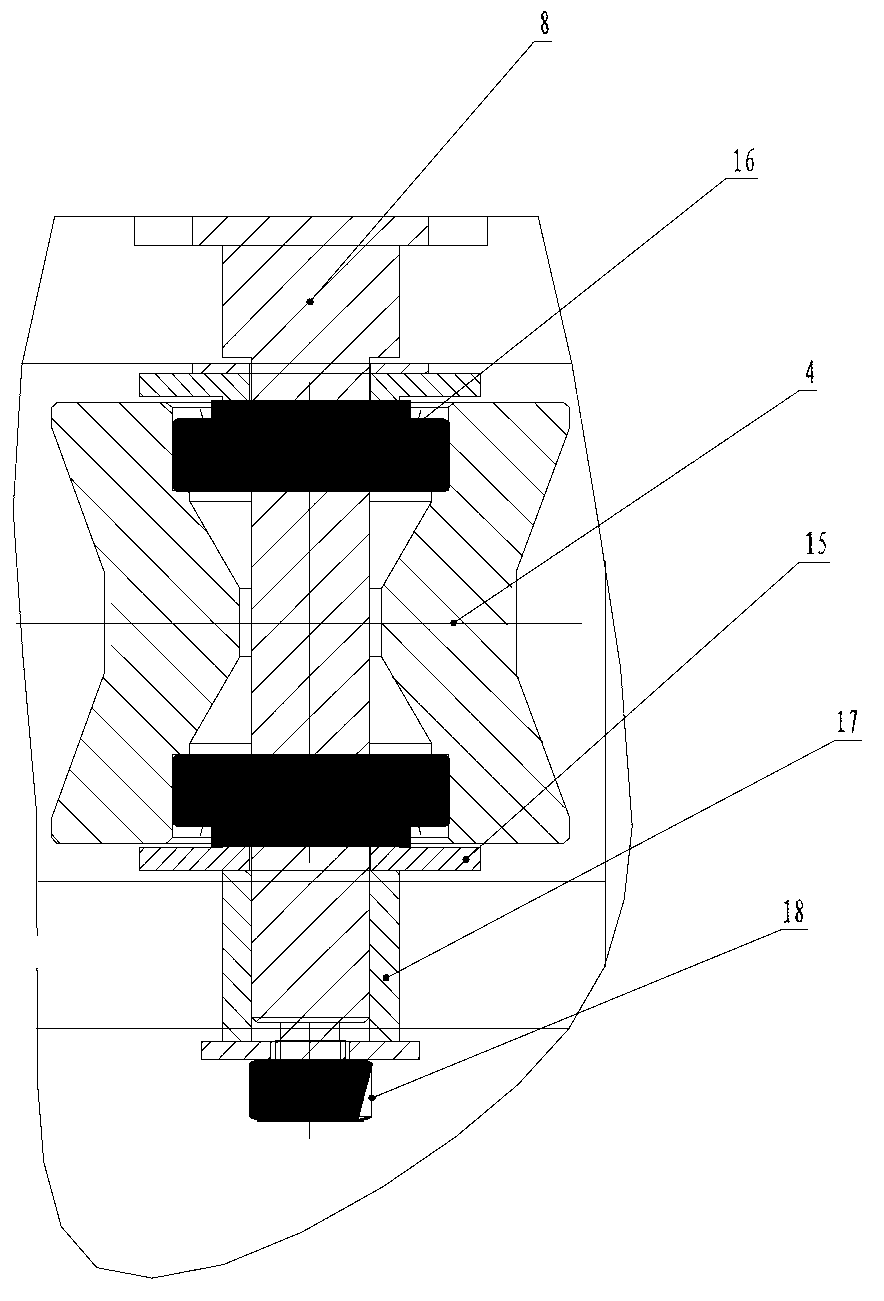

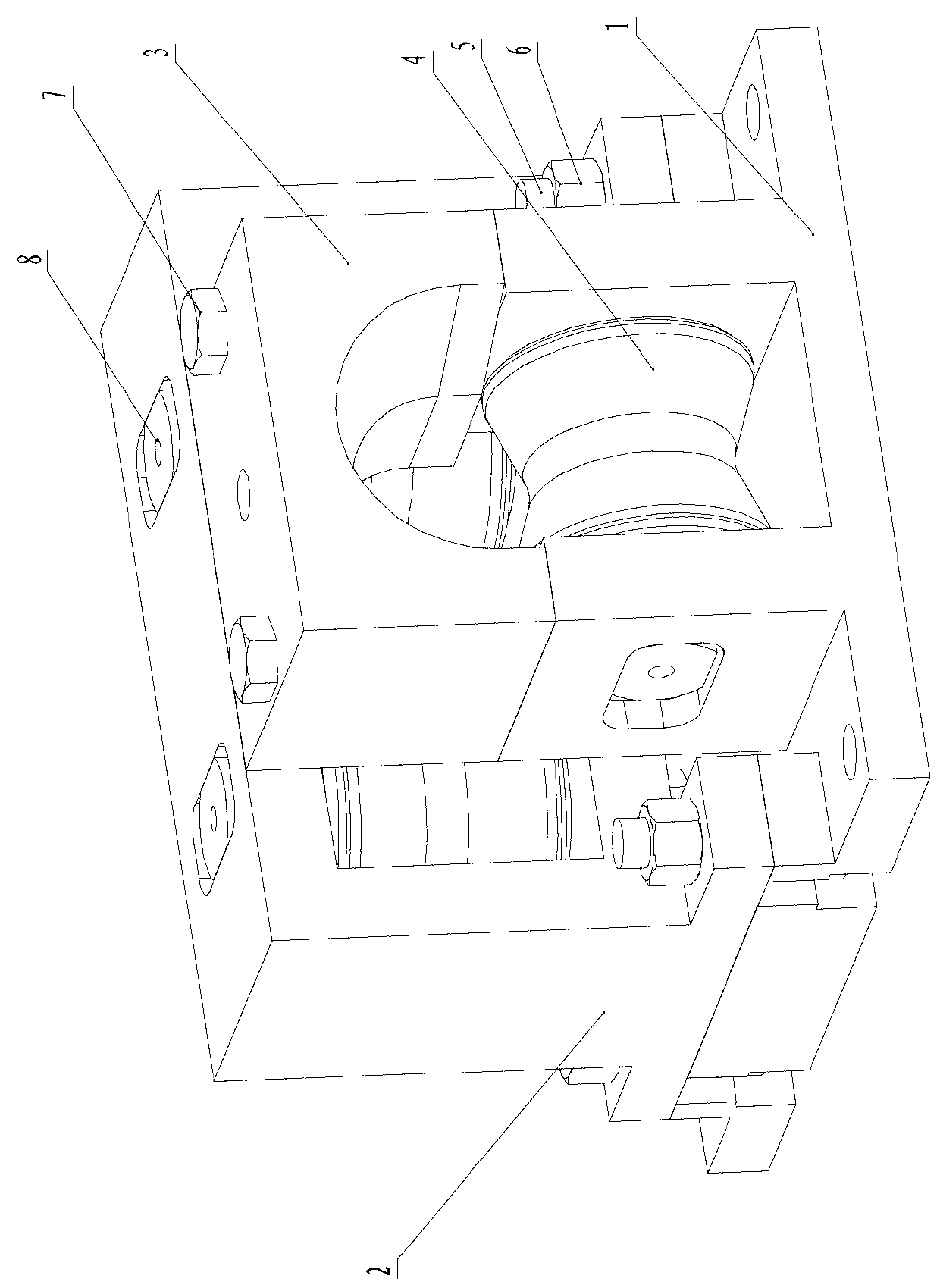

[0014] An anti-scratch rolling guide groove provided in this embodiment has a structure as shown in the figure, including a rolling element device 9 and a sliding guide groove 10 . Among them, the rolling body device includes a lower guide roller seat 1, which is equipped with a lower guide roller 4, and the rolled piece passes on the guide roller, and the guide roller can hold up the rolled piece; Left and right guide roller housing 2, left and right guide roller 5 and right guide roller 6 that are equated with lower guide roller size are respectively equipped with in this left and right guide roller housing, can prevent like this rolling piece side from being scratched. Then the left and right guide roller seats are fixed on the lower guide roller guide roller seats by connecting bolts and nuts. At the same time, a guide roller shaft 8 runs through the lower guide roller, wherein a bearing 16 is arranged symmetrically in the center of the outer side of the guide roller shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com