Material sheet stamping device

A punching device and blank technology, applied in metal processing equipment, perforation tools, manufacturing tools, etc., can solve the problems of cutting material size error, high processing price, low production efficiency, etc., to save production costs, reduce operators, Solve the effect of low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

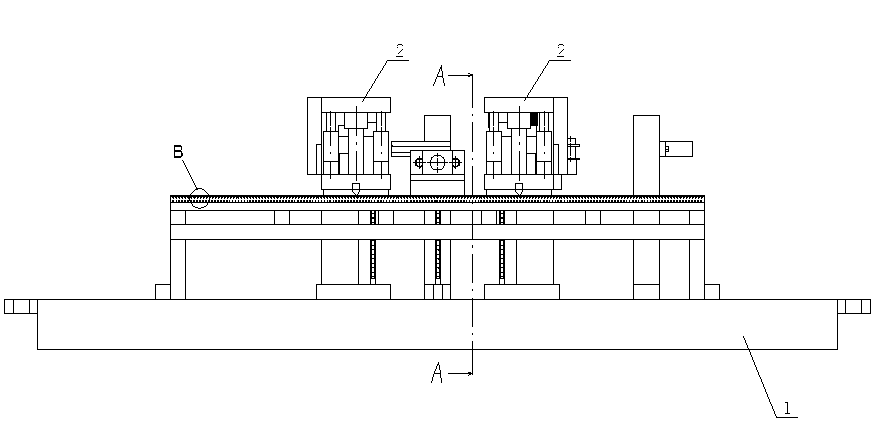

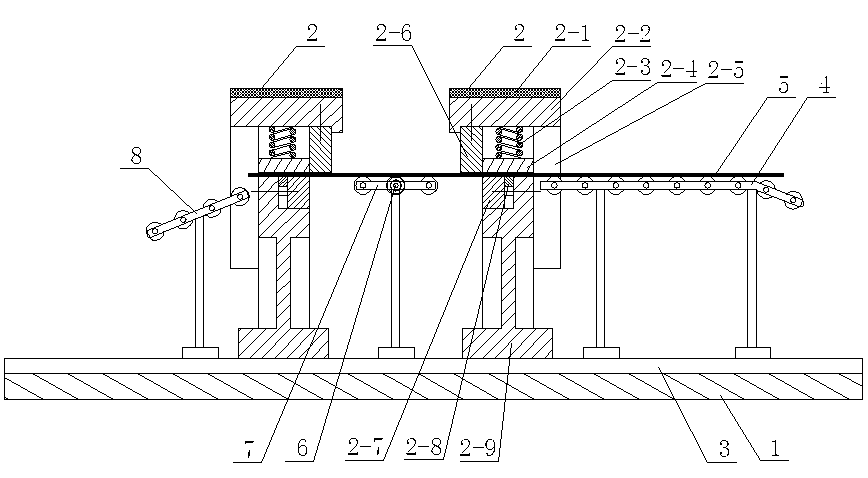

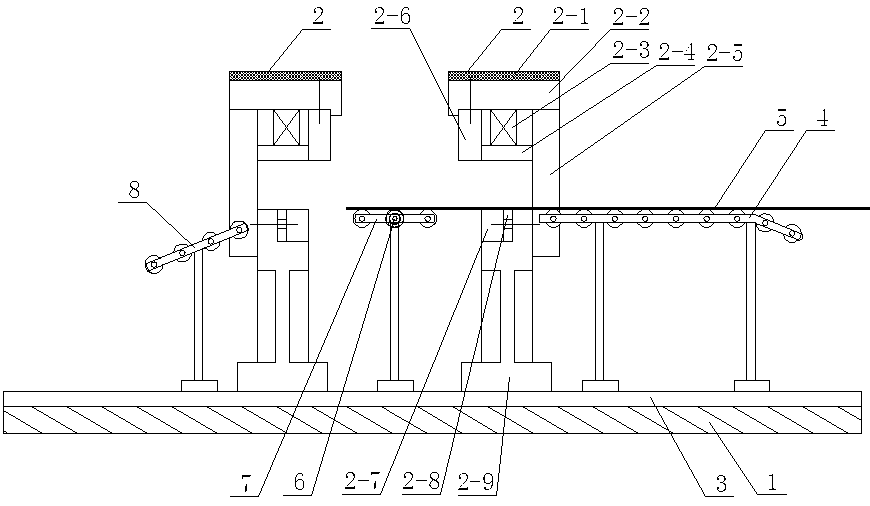

[0024] like figure 1 As shown in -6, the present invention mainly includes a base 1, a scale 13 is set on the base 1, a T-shaped groove 3 is set on the base 1, a front bracket 4 is set on the base 1, two sets of punching modules 2 are set on the base 1, One side of each group of punching modules 2 is respectively provided with a discharge frame 8 . The base 1 is also connected to a vertically arranged first air cylinder 6 , which is arranged between two groups of punching modules 2 , and the telescopic end of the air cylinder 6 is connected to a support frame 7 .

[0025] Each group of punching modules 2 is respectively connected to the second cylinder 12 arranged vertically, and the telescopic end of each second cylinder 12 is connected to the movable block 10 respectively, and each movable block 10 is connected to the roller 11 respectively, and each roller 11 is respectively supported on the base 1 on. Each group of punching modules 2 includes a lower mold base 2-9 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com