Method for producing modified half-hollw section of pure copper

A manufacturing method, semi-hollow technology, applied in wire drawing dies, metal extrusion dies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

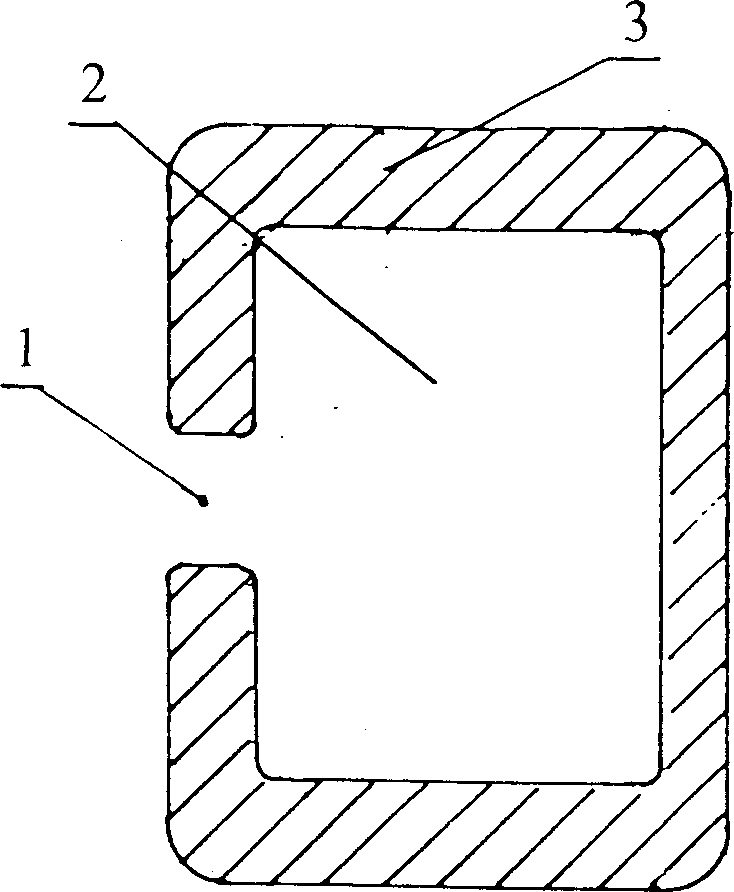

[0067] A method for manufacturing a C-shaped high-precision pure copper semi-hollow profile, the method includes the following processing techniques:

[0068] 1. Hot extrusion process of V-shaped billet with enlarged opening

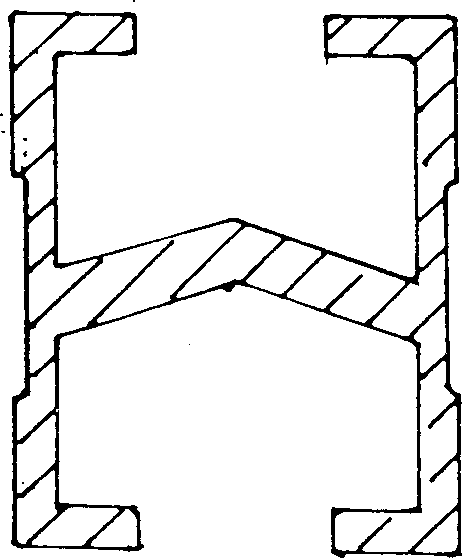

[0069] Heat a 46kg ingot weighing 46kg that meets the quality standard of pure copper for electricians to about 850°C, and use a V-shaped hot extrusion die (32) to Produced by conventional hard mold hot extrusion process. The die cavity of V-type hot extrusion die (32) is V-shaped, and its opening is greater than the opening that C section bar requires. The ratio of the area A enclosed by the tongue of the mold to the tongue base (6) and the area W of the axial section (10) of the width of the tongue base is less than or equal to 1.0.

[0070] The V-type hot extrusion die (32) is positioned with the tongue-shaped die holder (33) by the positioning pin hole (5), and is connected as a whole.

[0071] The outlet cone (8) is used to reduce extrusion resis...

Embodiment 2

[0083] A method for manufacturing a C-shaped high-precision pure copper semi-hollow profile. In addition to using a 32kg pure copper ingot for processing, the hot extrusion die, cold drawing combination die and subsequent auxiliary straightening and shaping used in the rest of the processing process Process conditions such as machine are all with embodiment 1.

[0084] Enhanced by the die holder in Figure 5 Figure 4 The V-shaped hot extrusion die shown can be hot-extruded to obtain 27.5kg of V-shaped billet with stable dimensions and high precision. The yield of the billet is 85%. The wall thickness tolerance of the billet is less than 2.5%. 15% machining margin; passed Image 6 The cold drawing combined die shown, according to Figure 7 The cold stretching process for processing semi-hollow profiles shown in the figure can obtain 25kg of high-precision C profiles, with a yield of 90%, and the wall thickness tolerance of C profiles is less than 2.5%. It is carried out on t...

Embodiment 3

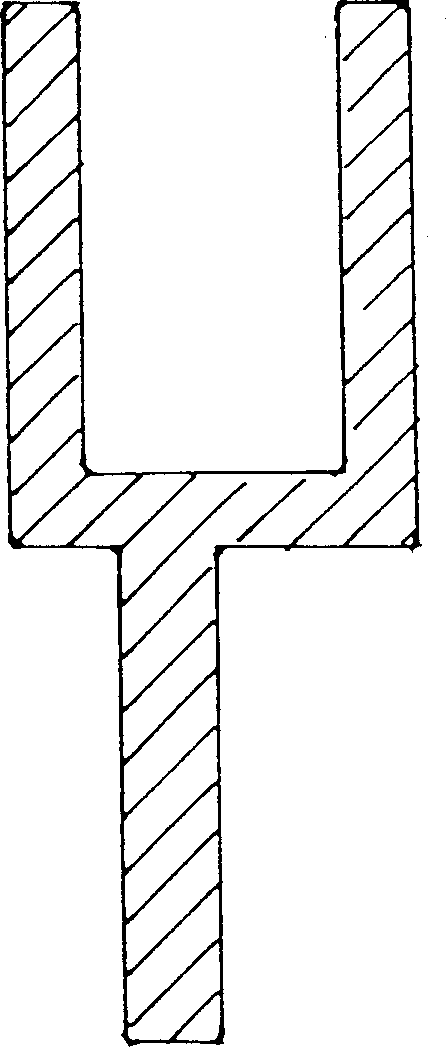

[0087] A method for manufacturing a fork-shaped pure copper semi-hollow profile, the processing technology of this method is similar to that of Embodiment 1. When processing a 60kg ingot weighing 60kg in accordance with the quality standard of pure copper for electricians, when processed under the same conditions as in Example 1, the fork-shaped pure copper material used by processing the fork-shaped pure copper material shown in Figure 10 reinforced by the mold holder shown in Figure 11 Approximate V-shaped hot extrusion die can be hot-extruded to obtain 54kg of fork-shaped blanks (approximately V-shaped or Y-shaped) with stable dimensions and high precision, and the blank yield is 90%. The blank has more than 25% processing allowance for further cold forming, and sufficient cold working allowance is to ensure that the fork profile has a thickness of 300N / mm 2 The above necessary conditions for high strength.

[0088] By processing the fork-type pure copper semi-hollow profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com