Adaptive-centering optical lens mounting device and optical element interval control method

A technology of optical lens and mounting device, which is applied in the direction of optical elements, mounting, optics, etc., can solve problems such as complex processing and manufacturing difficulties, avoid excessive drop in centering accuracy, reduce the impact of imaging quality, and make surface processing and manufacturing easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

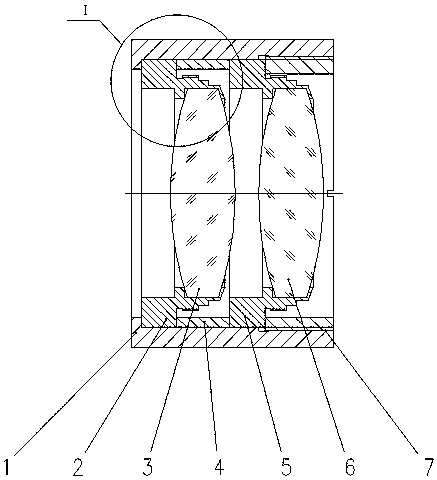

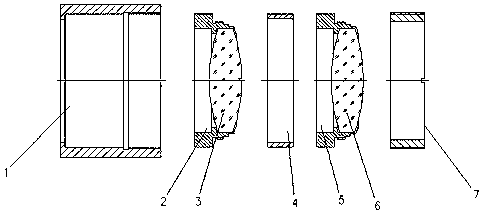

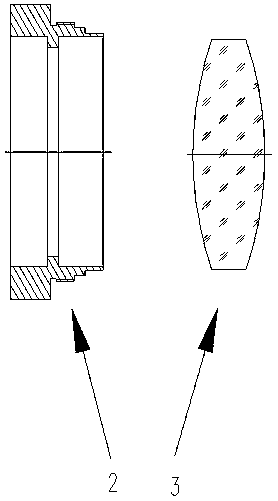

[0031] like Figure 5-8 As shown, this self-adaptive centering optical lens installation device, the optical lens includes: a lens barrel 1, a first roll edge mirror base 2, a first optical element 3, a spacer 4, a second roll edge mirror base 5, a first Two optical elements 6, pressure ring 7;

[0032] The first optical element 3 is assembled on the first roll edge mirror base 2, the second optical element 6 is assembled on the second roll edge mirror base 5, the first roll edge mirror base 2, the spacer 4, the second roll edge mirror base 5. Put them into the lens barrel 1 in turn, and fasten them in the lens barrel through the thread of the pressure ring 7;

[0033] The left side of the first roll side mirror base (2) is a cylinder, the longitudinal section of the cylinder is an isosceles trapezoid, and the cylinder and the lens barrel (1) are in line contact; the left side of the second roll side mirror base (5) It is a cylinder, the longitudinal section of the cylinder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com