A numerical control forming machine for plate-fin heat exchanger fins

A plate-fin heat exchanger and forming machine technology, applied in heat exchange equipment, etc., can solve problems such as unstable operation, slow pitch adjustment speed, insufficient torque, punch processing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

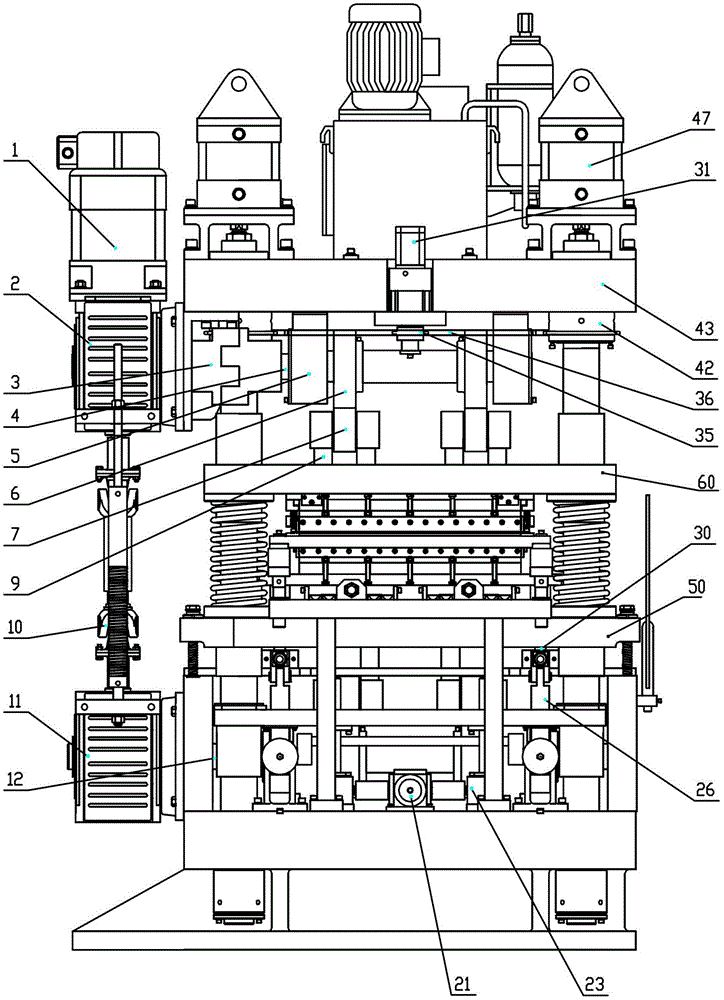

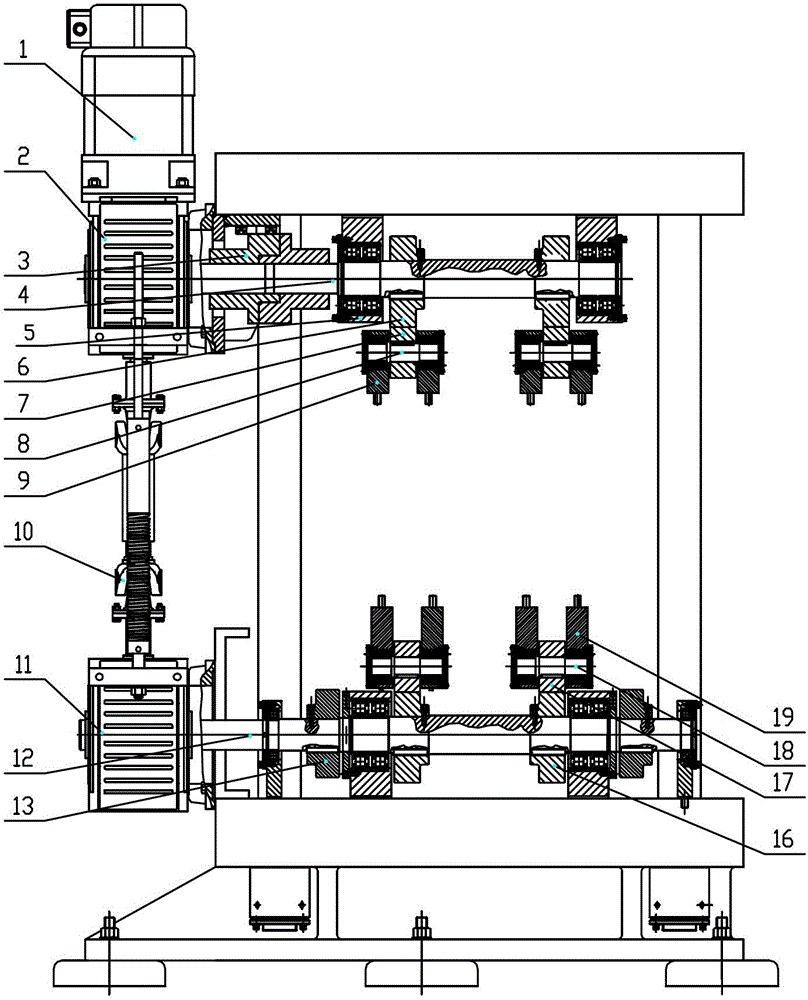

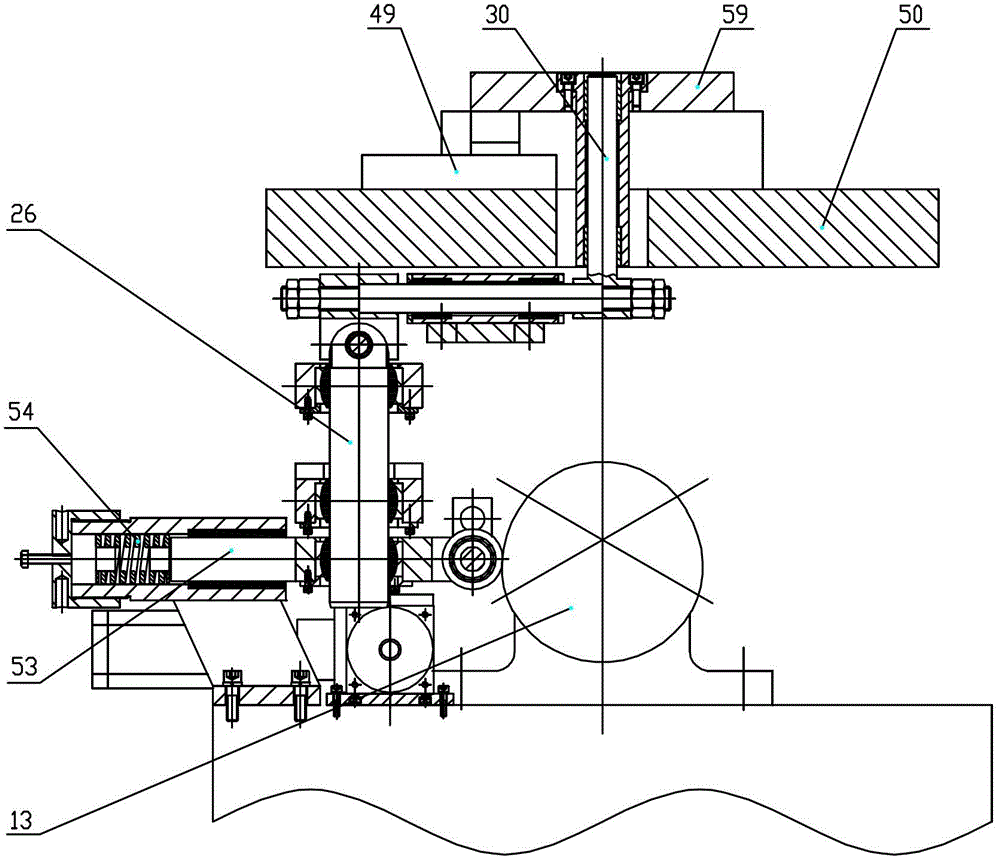

[0019] Such as figure 1 , 2 . The plate-fin heat exchanger fin CNC forming machine shown in 3 includes an upper template 60, a lower template 50, a spindle servo motor 1, and a control box (not shown) with a touch screen, which is arranged in the control box PLC controller, the touch screen is connected with the PLC controller; the top of the upper template 60 is provided with an upper spindle 4, the upper cam seat 5 is installed on the upper spindle 4, the upper cam 6 is installed on the upper cam seat 5, and the upper cam 6 is installed below There is an upper roller 7 that can be pushed by the upper cam 6 to reciprocate up and down. The upper roller 7 is fixed on the upper roller shaft support 9 through the upper roller shaft 8, and the upper roller shaft support 9 is fixed with the upper template 60; A lower main shaft 12 is provided, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com