Integrated vertical gas-electric vertical welding special equipment

A technology of vertical gas-electric vertical welding and special equipment, applied in arc welding equipment, welding equipment, welding equipment and other directions, can solve problems such as increased construction cost and achieve the effect of reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

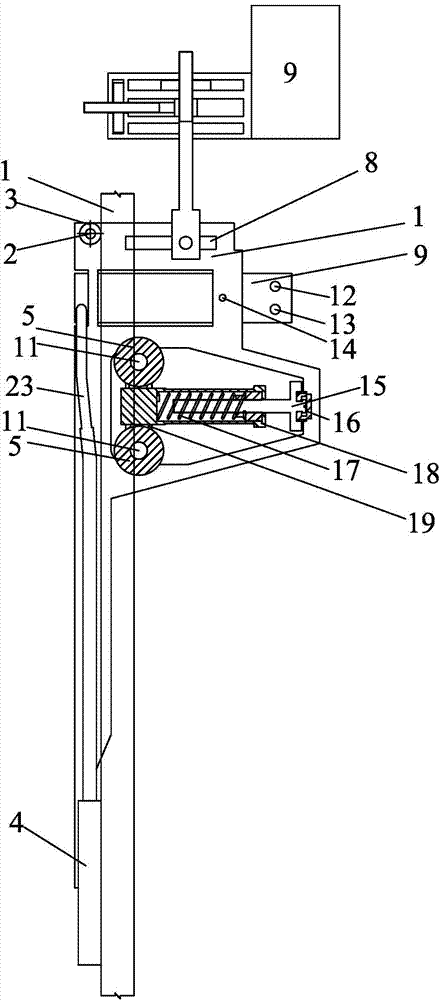

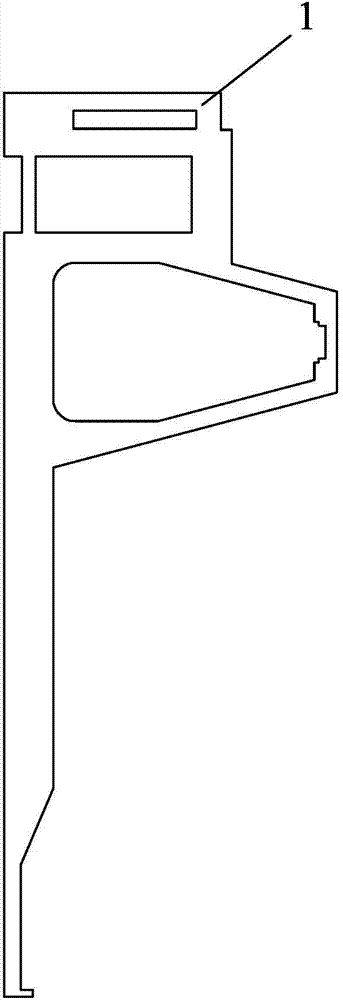

[0047] Such as figure 2 and image 3 As shown, the special equipment for vertical gas-electric vertical welding includes a plate-shaped frame body 1, and the plate-shaped frame body 1 is divided into the straight edge side (left side in the figure) behind the back of the steel plate 10 to be welded and the plate-shaped frame body 1 located on the back side of the steel plate 10 to be welded. There are two parts on the special-shaped side (right side in the figure) of the front face of the steel plate 10. Wherein the support body upper part of straight side side perforates wheel axle 2 to set positioning wheel 3 after; Correspondingly, the back slider 4 is provided with a hole structure for hooking with the hook structure of the plate-shaped frame body, and also provided with a trapezoidal groove for realizing forced forming of the weld seam.

[0048] The front end faces of the positioning wheel 3 and the back slider 4 are in a plane, and are used to fit the back side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com