Air leakage mending set

A technology for air leak repair and kits, applied to tires, other household appliances, household appliances, etc., can solve problems such as fitting deviation, increase in travel cost, and decrease in yield, and achieve the effect of eliminating operational errors and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described in detail.

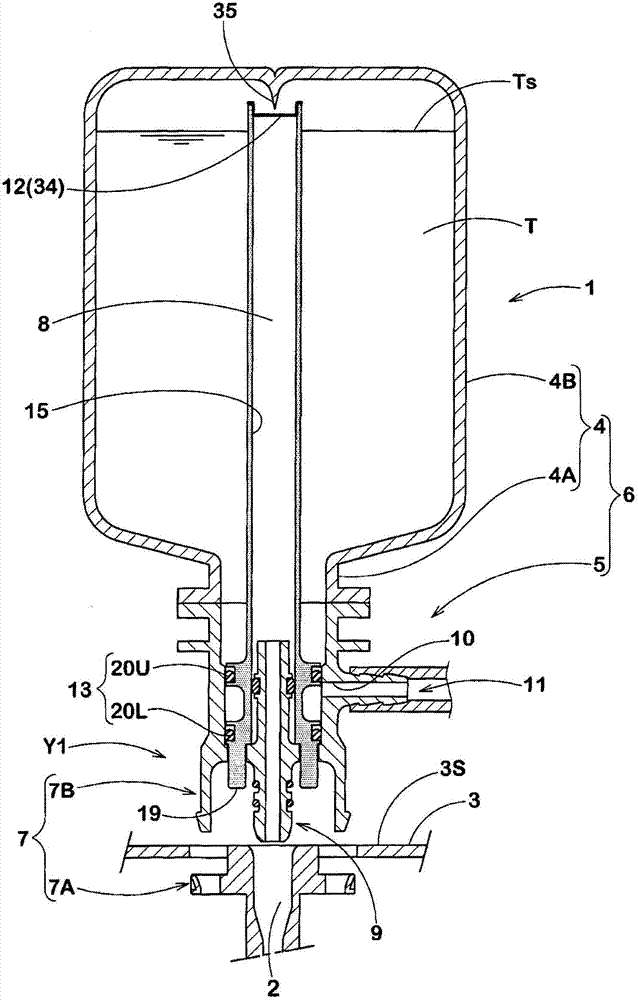

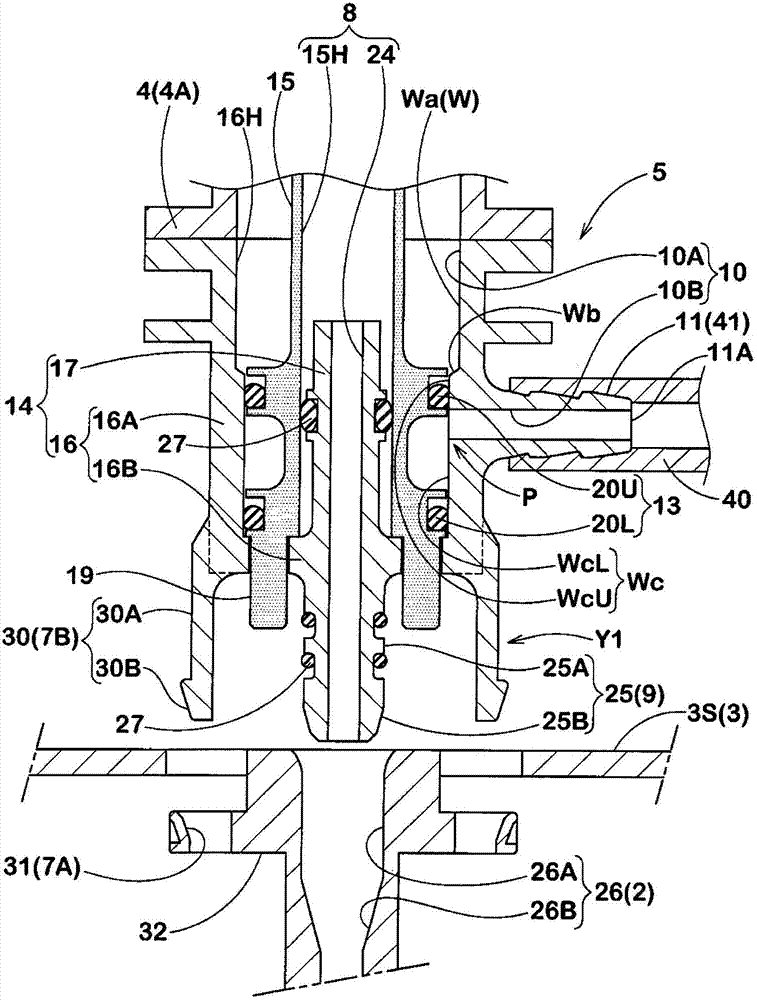

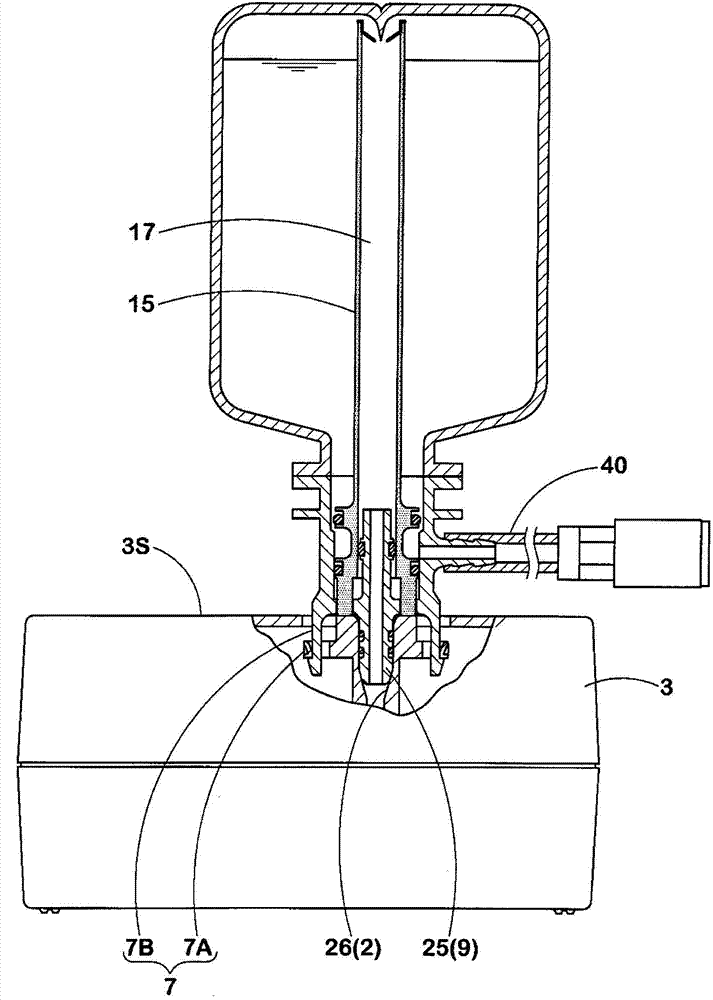

[0040] figure 1It is a cross-sectional view showing a state Y1 before connection of the leak repair kit 1 of the present invention. The leak repair kit 1 of the present embodiment includes a compressor 3 having a compressed air discharge port 2 for discharging compressed air. bottle unit 6, the bottle unit 6 is equipped with a draw-out cover 5 in the bottle container 4 containing the air leakage repair fluid T; The extraction cover 5 is connected with the compressor 3 and fixed as a whole.

[0041] Wherein, the connecting unit 7 is configured to include: a compressor-side connecting portion 7A formed on the compressor 3; and a drawing-out cover-side connecting portion 7B formed on the drawing-out cover 5. The compressor 3 and the bottle unit 6 are integrally fixed by connecting both 7A and 7B at the air leakage repair site. Thereby, it is possible to prevent the bottle unit 6 from falli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com