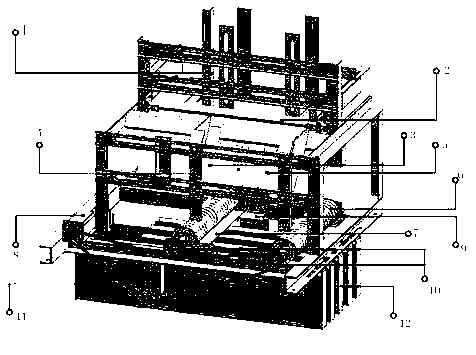

Cutting board spiral material dividing mechanism of automatic carton partition board insertion machine

A technology of screw material distribution and screw mechanism, which is applied in paper/cardboard containers, container manufacturing machinery, containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

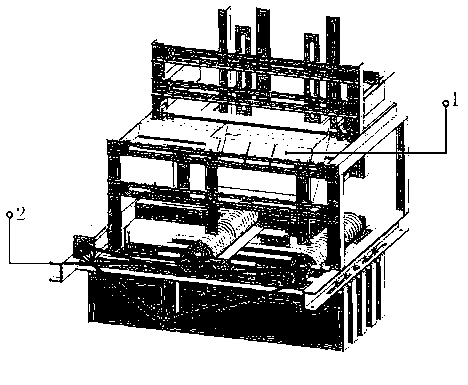

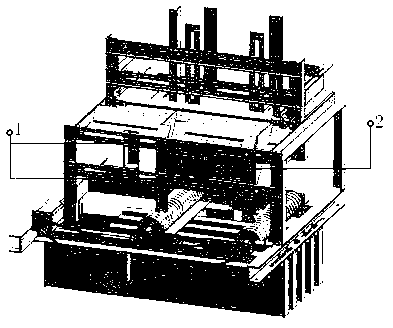

[0024] The accompanying drawings of this specification have clearly listed the overall structure of the machine and the structural details of each part. The description part also gives a detailed description of the working process of the machine and the working principle of each part. When making the machine according to this scheme, the size of the machine should also be designed according to the size range of the packaging cartons to be plugged.

[0025] The control system of the machine makes the machine a whole with coordinated actions of various parts, and there is a strict sequence and timing relationship between each action. For example, after the knife plate has settled down on the inclined material path, the air port can spray air to make the knife plate stand up. After the knife plate falls into the screw space, the screw can rotate and advance. It is recommended to use the PLC controller to complete these cooperations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com