Laser marking machine for detecting capsules

A laser marking and capsule detection technology, applied in typewriters, printing and other directions, can solve the problems of poor marking effect, unstable operation of conveyor chain, unstable rotation, etc., to achieve low missed detection rate and avoid overlapping blur phenomenon. , the detection effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

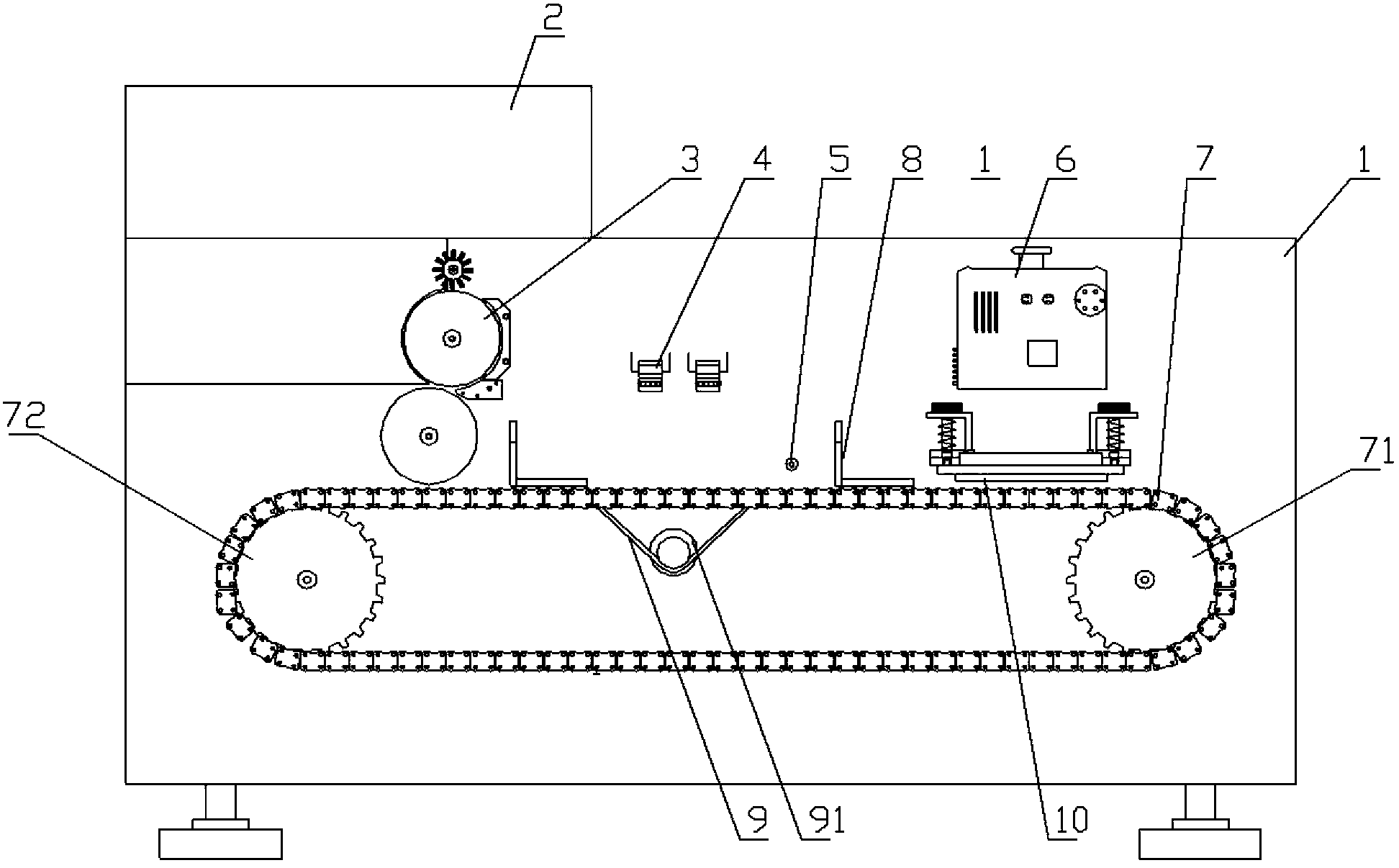

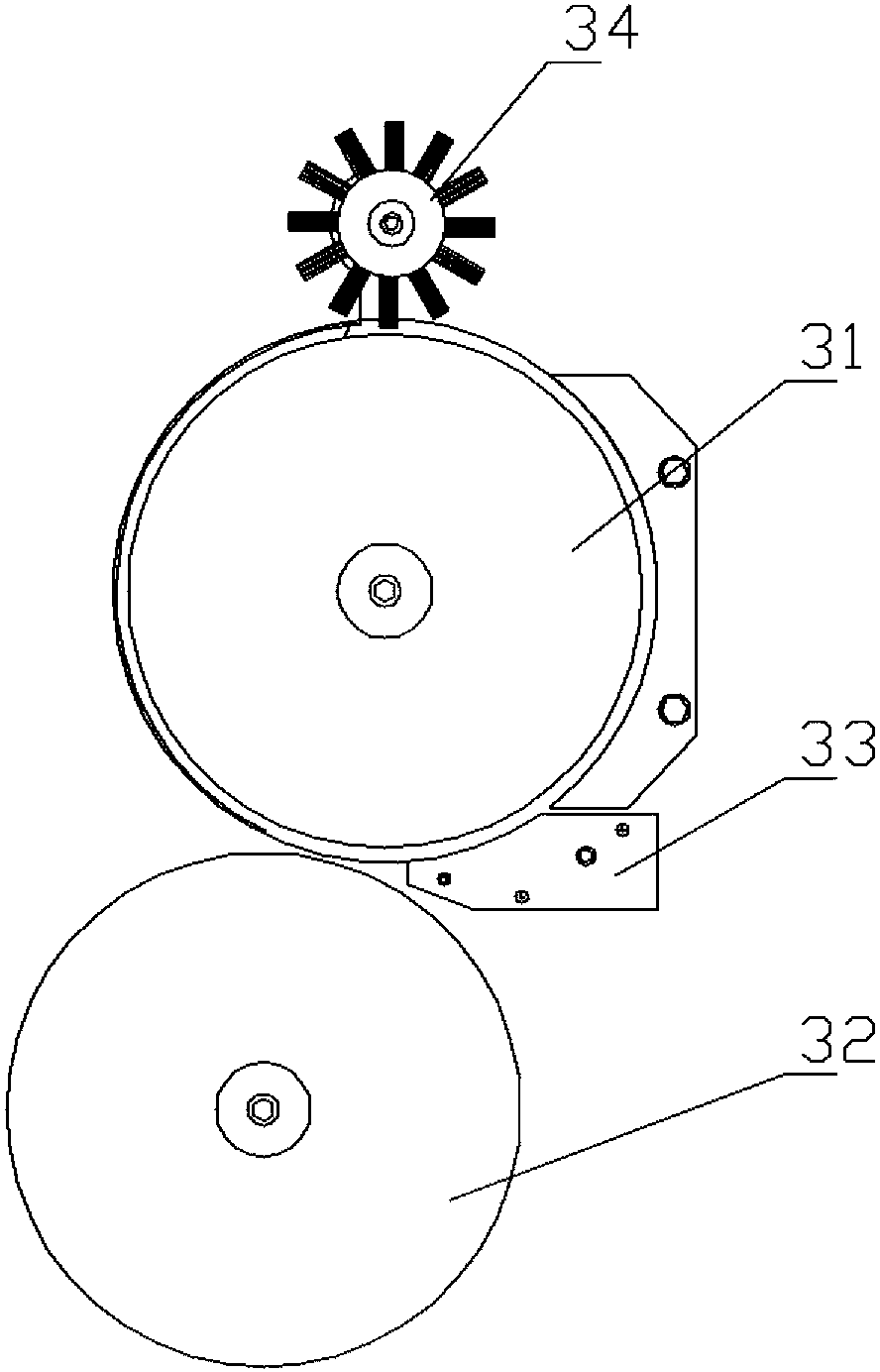

[0026] Example: see Figures 1 to 7 As shown, the all-in-one capsule detection and laser marking machine includes a frame 1, a vibrating feeding tray 2, a capsule positioning and arrangement device 3, a capsule image detection device 4, an air blowing nozzle 5, and a capsule laser marking device 6. A conveying chain 7 is installed on the top of the conveying chain 7, and a capsule positioning arrangement device 3, a capsule image detection device 4, an air blowing nozzle 5 and a capsule laser marking device 6 are arranged in sequence from left to right above the conveying chain 7,

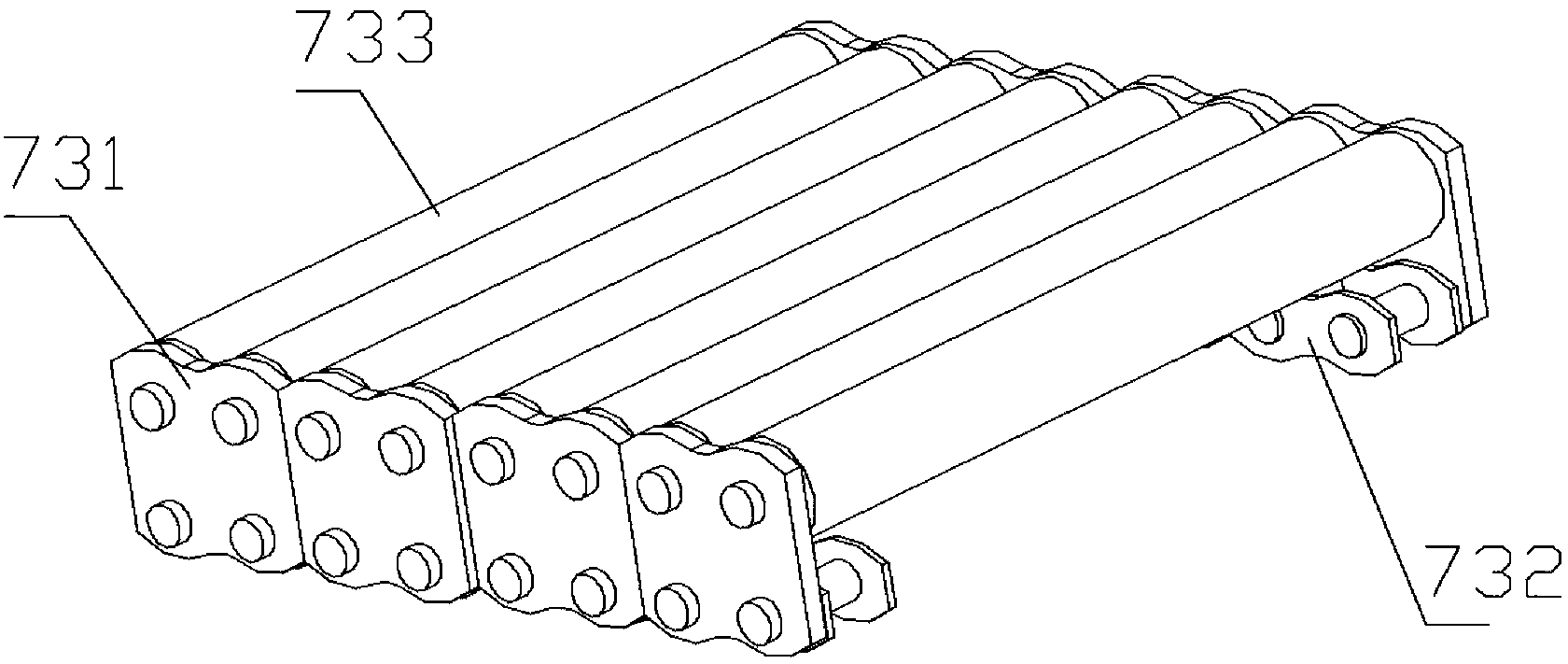

[0027] Conveyor chain 7 is made up of driving sprocket 71, driven sprocket 72 and conveyor belt 73, and conveyor belt 73 is made up of clip 731, chain 732, roller 733, and two chains 732 are respectively fixed on two clips 731, two The roller 733 is hinged on the two clips 731; the chain 732 is installed on the driving sprocket 71 and the driven sprocket 72, and the friction wedge belt 9 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com