Aircraft flap mechanism having compact large fowler motion providing multiple cruise positions

一种飞行器、襟翼的技术,应用在气动襟翼延伸机构领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

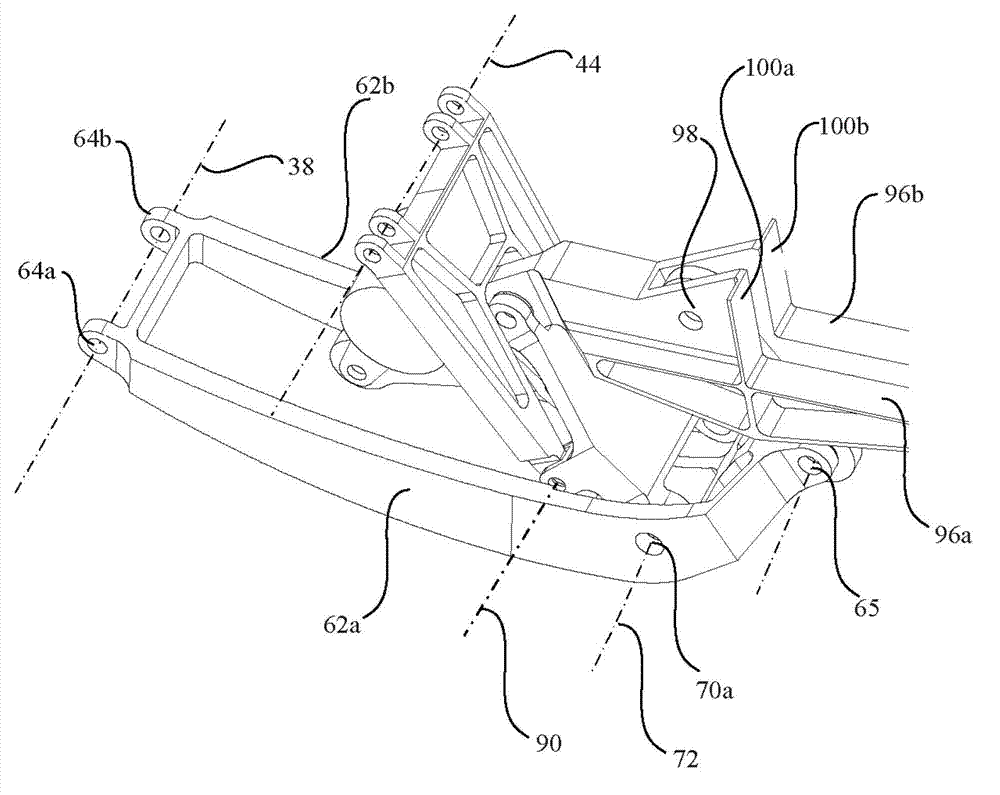

[0048] Embodiments disclosed herein provide a mechanism with large flap Fowler motion in a compact volume. Provides kinematic and link arrangement differentials that allow initial forward or aft motion in the flaps to be relatively small and roughly parallel to the wing lower surface while driving rapid changes in angle (for the TEVC range), and after commencing TEVC range motion, Provides faster Fowler extensions with varying angles. This is critical for TEVC capability as well as mid-flap position with drooping spoilers.

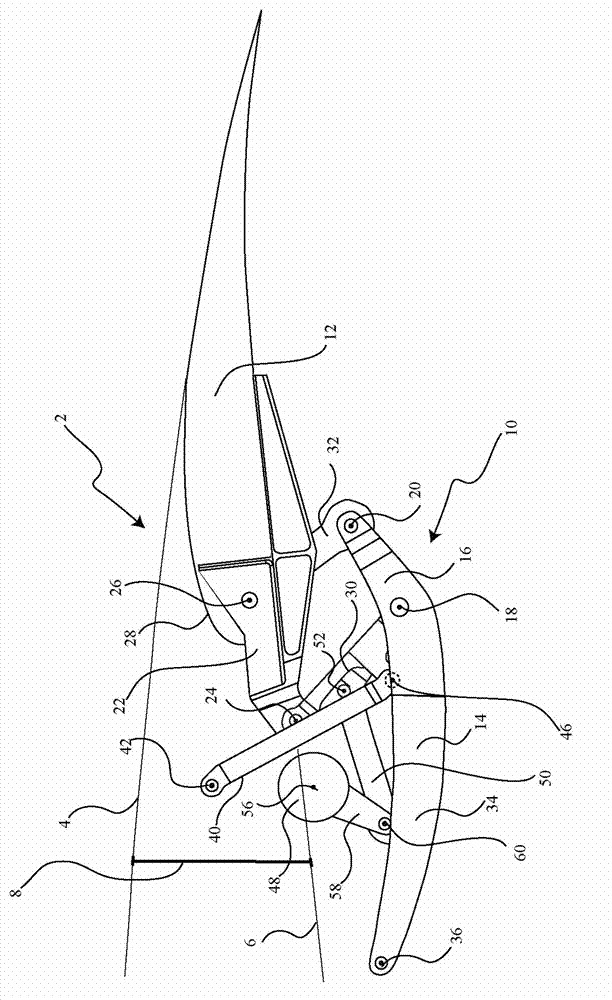

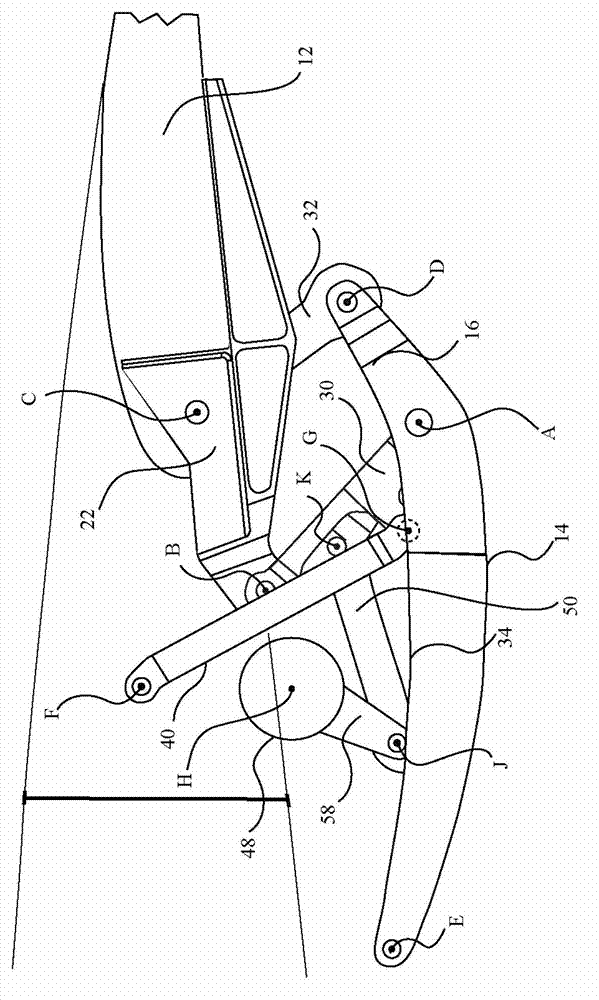

[0049] As shown in the example embodiment in FIG. 1 , a pivot mechanism 10 for an aerodynamic flap 12 , hereinafter referred to as a flap, provides large Fowler motion, TEVC and droop motion. Mounted in the wing 2, the mechanism, having an upper surface 4 and a lower surface 6 including a rear beam 8, comprises a hinged support quadrilateral joint with a support beam 14 including a rear portion 16 having a An axis of rotation 18, and an axis of rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com