Support assembly for locking structure of rotation arm and combined mirror of onboard head-up display

A technology of locking structure and rotating arm, which is applied to aircraft parts, transportation and packaging, etc. It can solve the problems of large installation space, complex structure of locking mechanism, low reliability and safety, and achieve reliable locking, reliable locking and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

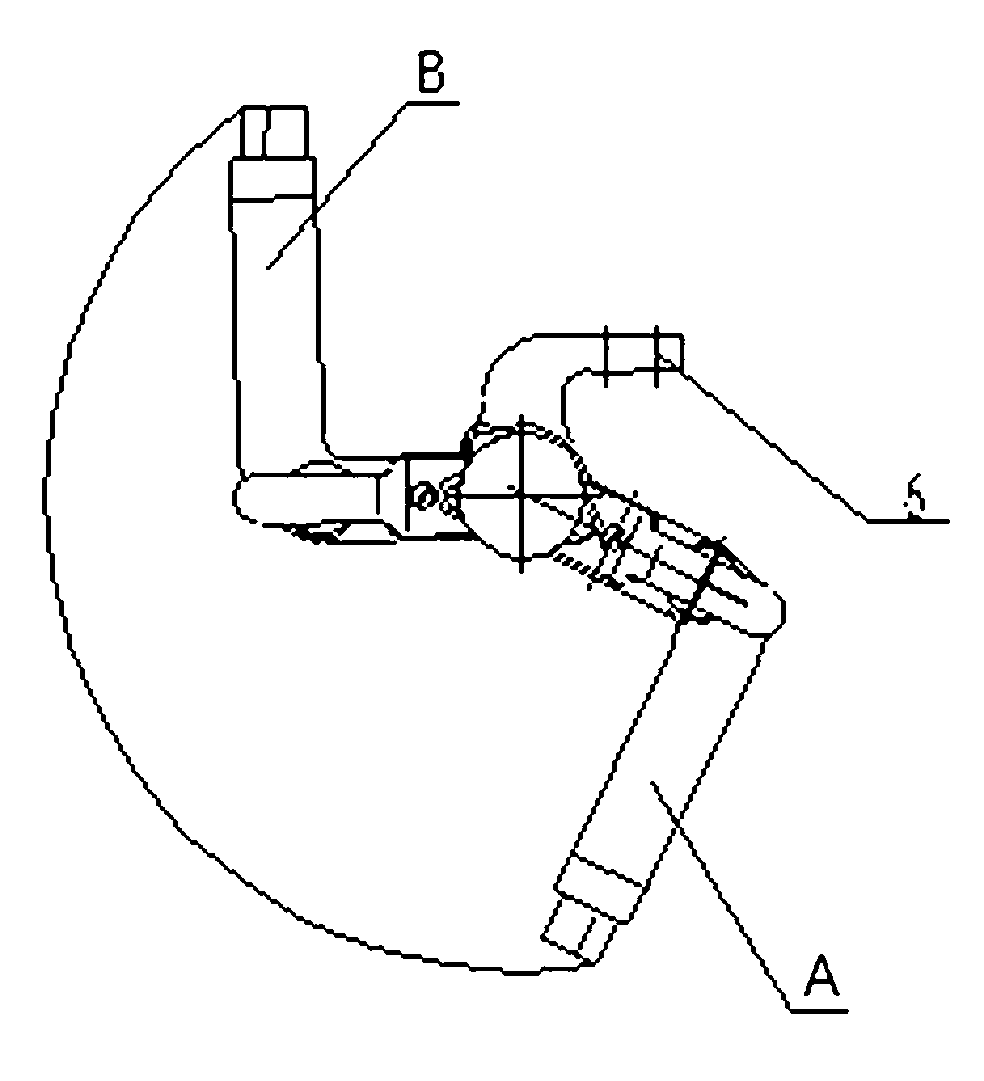

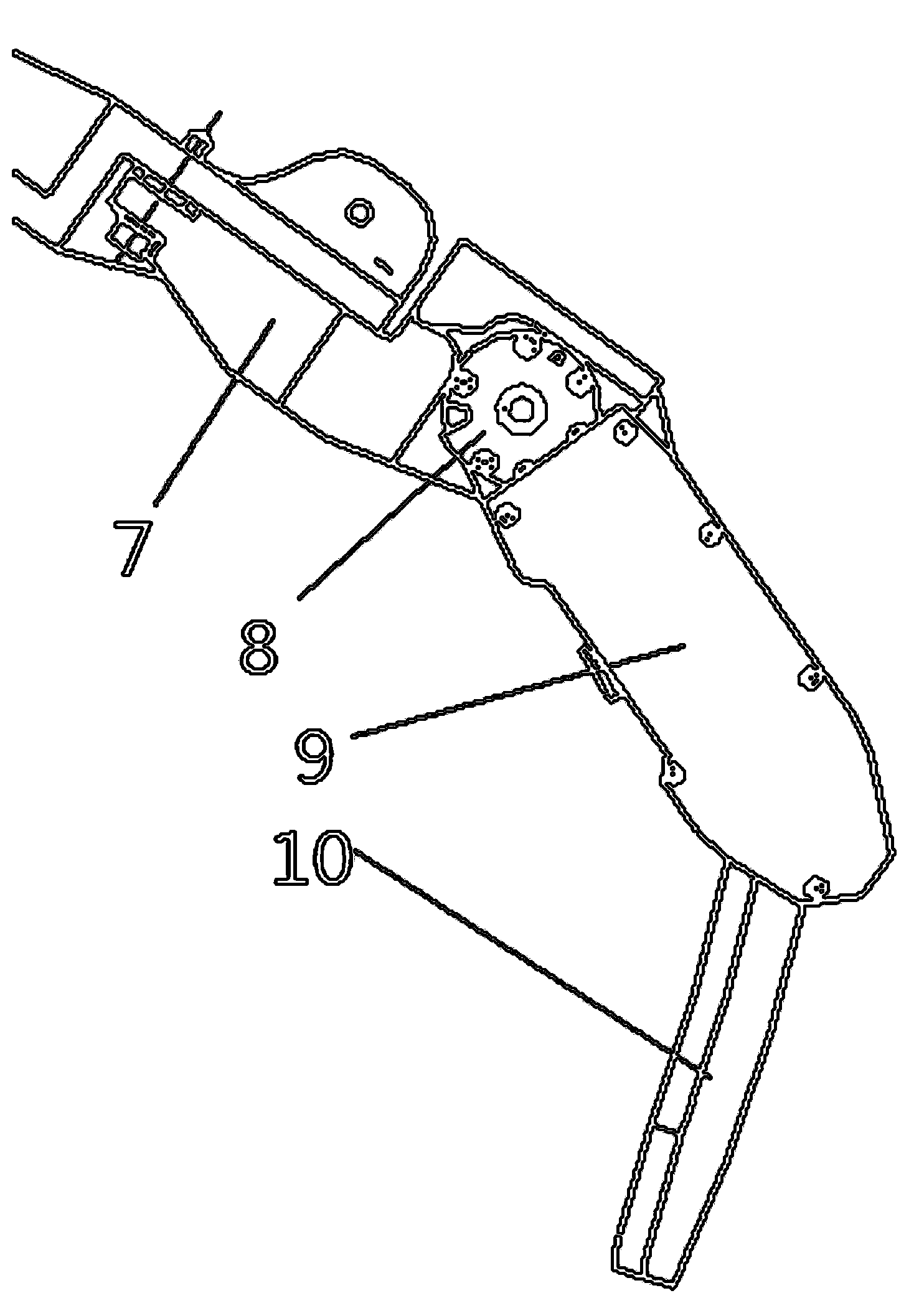

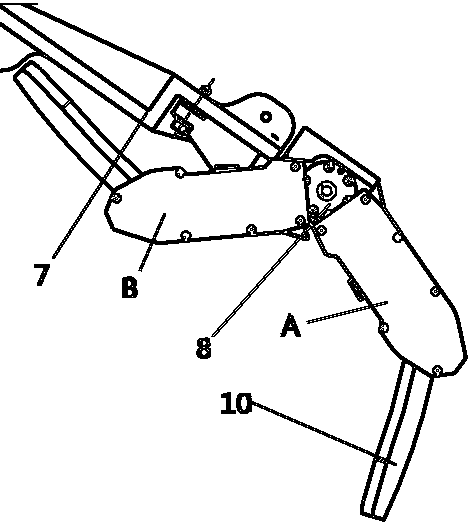

[0021] Embodiments of the bracket assembly for the combination mirror of the airborne head-up display Figure 3~5 As shown: it includes the mounting support 7 for being installed on the corresponding body and the combination mirror mounting frame which is rotatably assembled on the mounting support 7 and has a stowed position and an unfolded position. The frame is positioned at the locking structure of the stowed position B and the unfolded position A. The locking structure includes a positioning wheel 8 arranged on the mounting support 7, axially consistent with the rotation axis of the rotating arm 9, and coaxially rotating with the positioning wheel. Cooperating rotating arm 9, the front end of rotating arm 9 is equipped with glass frame, and glass frame comprises the glass bearing that is used for installing corresponding combination glass 10 that is rotatably arranged on rotating arm 9 front end. The outer circumference of the positioning wheel 8 is provided with position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com