Intelligent industrial sewing electronic bobbin winder

A kind of winder and sewing technology, which is applied in the direction of bobbin winding in sewing machines, sewing equipment, sewing machine components, etc., can solve the problems of economic loss, low use efficiency, frequent failures, etc., and achieve the effect of broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

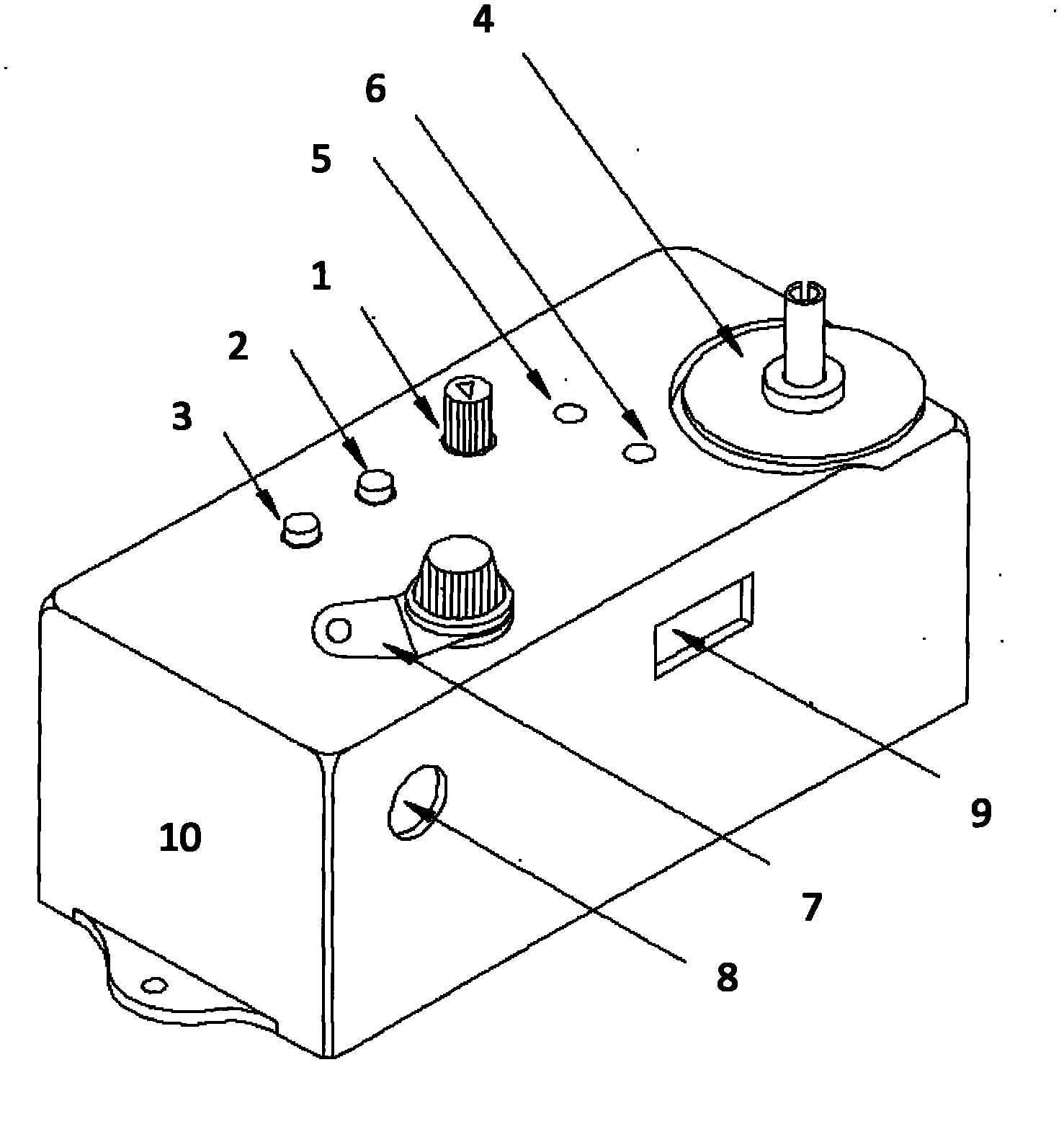

[0010] Embodiments of the present invention refer to figure 1 shown.

[0011] An intelligent seam electronic wire winder, including a housing, a wire winder, and a wire gripper, the wire winder and the wire gripper are located on both sides of the housing, and it is characterized in that: the smart seam electronic The winding device also includes a single-chip microcomputer, a switching power supply, a micro-DC motor, a circuit board, a power interface, an indicator light, a switch button, and an adjustable potentiometer, and the single-chip microcomputer, a circuit board, a switching power supply, and a micro-DC motor are located inside the housing The power interface, indicator light, switch button, and adjustable potentiometer are located outside the housing, and the single-chip microcomputer, power interface, indicator light, switch button, adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com