Working fluid level gauge for transmitting and receiving infrasonic waves and method thereof

A technology of infrasound wave and dynamic liquid level, applied in the field of automation equipment and oil exploitation, can solve the problems of easy divergence of wave packets, energy dissipation, environmental pollution, etc., and achieve the effect of overcoming the difficulty of accurate timing and overcoming easy divergence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

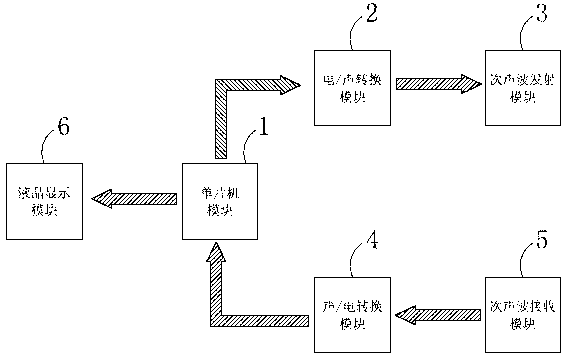

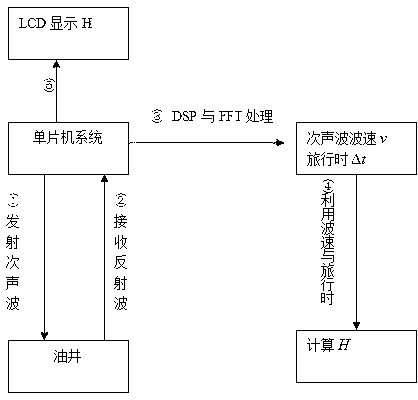

[0017] see figure 1 As shown, a dynamic liquid level instrument for transmitting and receiving infrasonic waves, which includes a single-chip microcomputer module 1, a first electric / acoustic conversion module 2 for converting electrical signals into infrasonic waves, an infrasonic wave transmitting module 3 for transmitting infrasonic waves, and a The second sound / electric conversion module 4, the infrasonic wave receiving module 5, and the liquid crystal display module 6 connected with the single-chip microcomputer module 1 are used to convert the infrasonic wave into an electric signal; one end of the first electric / acoustic conversion module 2 is connected with the single-chip microcomputer module 1 , the other end is connected to the infrasonic wave transmitting module 3; one end of the second sound / electricity conversion module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com