Suction type SF6 gas leakage monitoring method

A gas leakage and inhalation technology, which is applied in the direction of measuring devices, application of light to test fluid tightness, and material analysis through optical means, can solve the problems of limited application range and low monitoring accuracy of leakage monitoring systems, and achieve compact and compact devices. The effect of high reliability and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

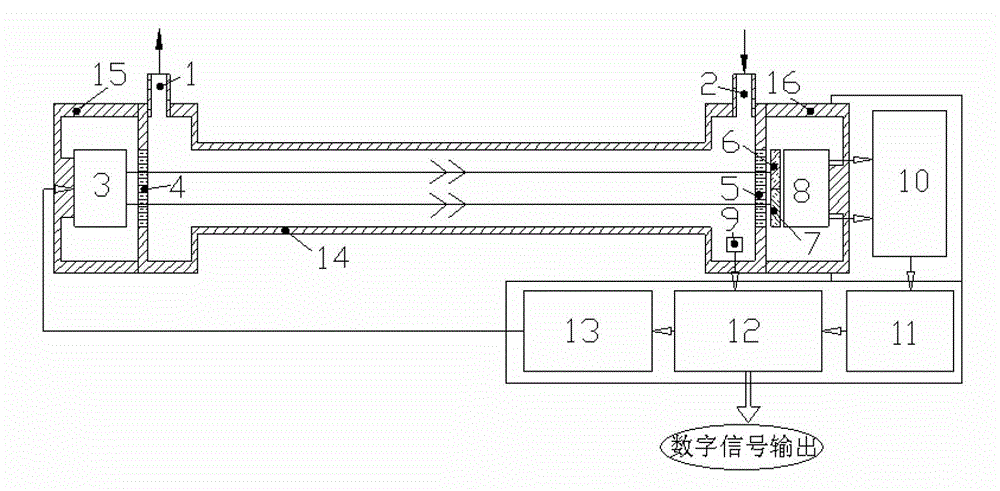

[0021] The concrete structure of this embodiment sees attached figure 1 The inner hollow device body 14 forms an air chamber, the inner wall of the air chamber is plated with gold reflective film, and an air outlet 1 and an air inlet 2 are arranged on it. Windows 4 and 5 are installed at both ends of the device body 14, so that the air chamber is sealed and not To hinder the transmission of infrared light, a temperature detector 9 is arranged in the gas chamber. The left side of the window 4 is provided with an infrared light source 3 , which is fixed by an end cover 15 and connected to the device body 14 . The right side of the window plate 5 is provided with a dual-channel infrared detector 8, and a reference filter 6 and a measurement filter 7 are respectively installed in front of the two passages of the dual-channel infrared detector 8, so that the dual-channel infrared detector 8 It can output a reference signal and a measurement signal, fix the dual-channel infrared de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com