Automatic sample feeding mechanism for light hydrocarbon

An automatic sampling, light hydrocarbon technology, applied in the direction of analytical materials, instruments, etc., can solve problems such as being unfavorable for repeated analysis, affecting the resolution, large pre-column dead volume, etc., achieving simple structure, small sampling volume, and peak output effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

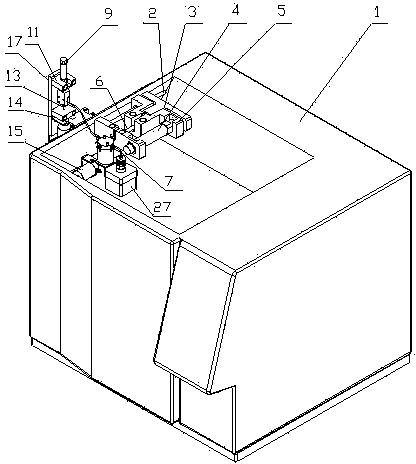

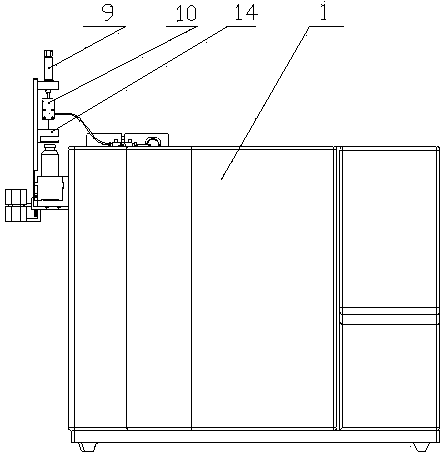

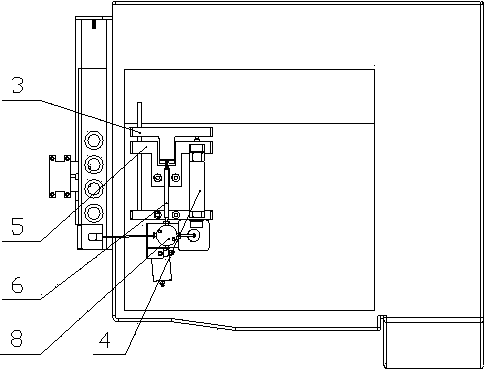

[0022] Such as Figure 1 to Figure 9 As shown, the light hydrocarbon automatic sampling mechanism is composed of a chassis 1, an injection component, a sampling component, a transmission positioning component and a four-way switching component. Analytical Instruments;

[0023] The injection assembly includes guide post 2, guide slider 3, cylinder A4, cylinder holder A5 and syringe 6;

[0024] The cylinder fixing seat A5 includes a front fixing block 51 and a rear fixing block 52, and the two fixing blocks are placed parallel to each other, and the corresponding two surface ends of the front fixing block 51 and the rear fixing block 52 are respectively processed with a fixed cylinder A4 cylinder block The support hole of the support hole and the support hole of a fixed guide post 2, the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com