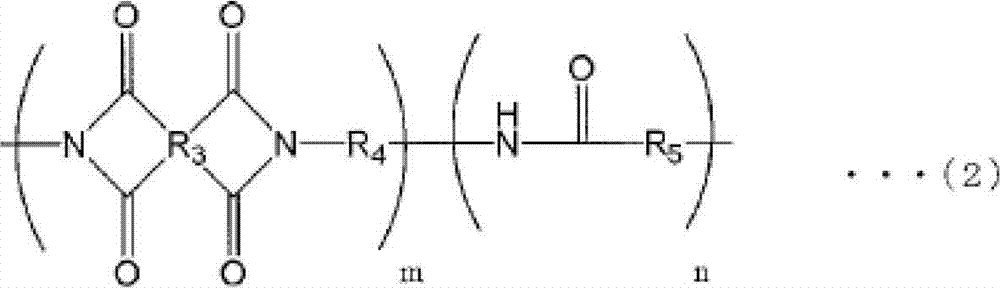

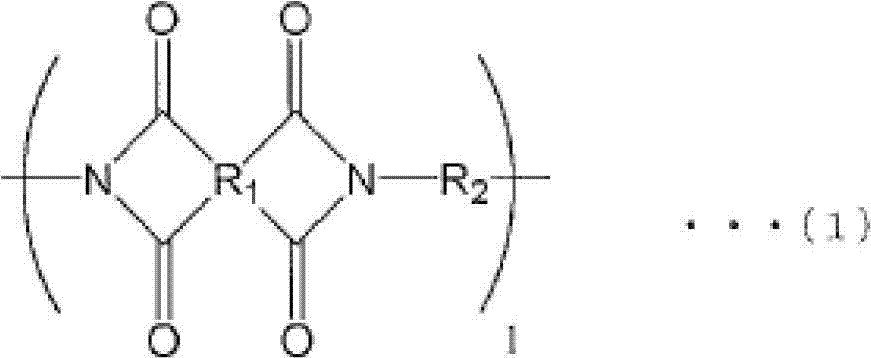

Negative electrode paste, negative electrode and method for manufacturing negative electrode, and non-aqueous electrolyte secondary battery

A technology of non-aqueous electrolyte and negative electrode slurry, which is applied in the direction of non-aqueous electrolyte battery electrodes, electrode manufacturing, and secondary batteries. Productivity, effect of suppressing dimensional change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0125]

[0126] 100g average particle size is 5μm, BET specific surface area is 3.5m 2 / g silicon oxide SiO x (x=1.01) into the batch heating furnace. The inside of the furnace is depressurized by an oil rotary vacuum pump, and the temperature is raised to 1,100°C. After reaching 1,100°C, CH 4 The gas was flowed in at 0.3 NL / min, and the carbon covering treatment was carried out for 5 hours. In addition, the degree of vacuum at this time was 800 Pa. Cool down after treatment to obtain 97.5g of SiO covered by carbon 2 Black particles in which Si particles are dispersed. The obtained black particles are conductive particles with an average particle size of 5.2 μm and a BET specific surface area of 6.5 m 2 / g, and the carbon coverage of the black particles was 5.1% by mass.

[0127]

[0128] Pour nitrogen into a 2L four-necked flask, and charge 192.0g (1.0 mole) of trimellitic anhydride as polyvalent carboxylic acid anhydride, and charge 250.0g (1.0 mole) of 4,4'-diph...

Embodiment 2)

[0143] Adjust the negative electrode slurry of the present invention, use 0.01 mass parts (relative to binder is 0.1 mass %) PP13-TFSI as ionic liquid, in addition, manufacture negative electrode and non-aqueous electrolyte under the same conditions as in Example 1 Secondary batteries, and various evaluations.

Embodiment 3)

[0145] Adjust the negative electrode slurry of the present invention, use 0.1 mass parts (relative to binder is 1.0 mass %) PP13-TFSI as ionic liquid, in addition, manufacture negative electrode and non-aqueous electrolyte under the same conditions as in Example 1 Secondary batteries, and various evaluations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com