Cultivator-hiller suitable for operation between ridges

A technology of a soil cultivator and a frame is applied in the field of agricultural machinery and can solve the problems of not providing trenching, ridge, and soil cultivating operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

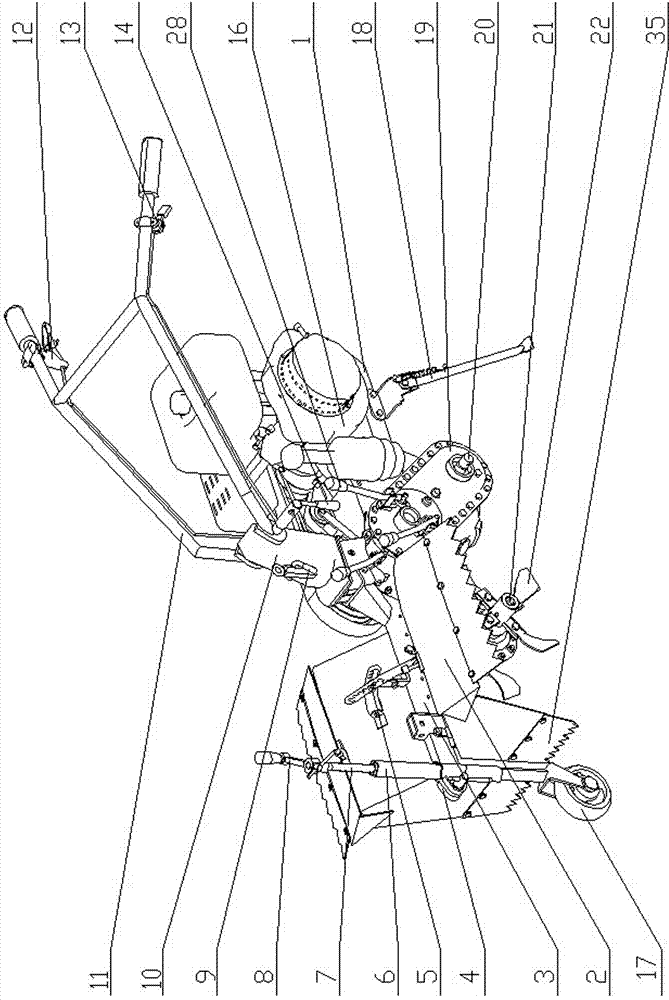

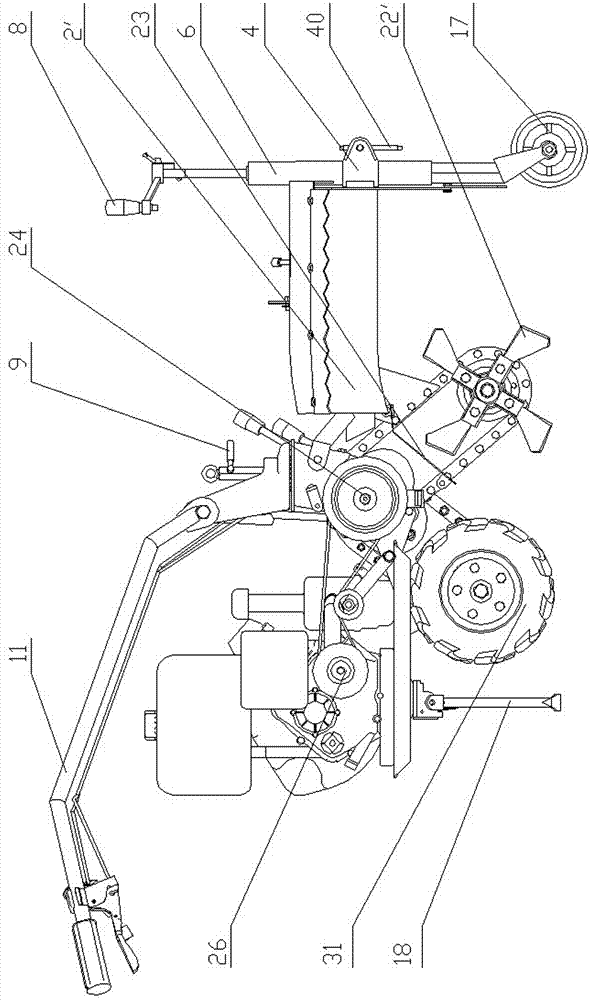

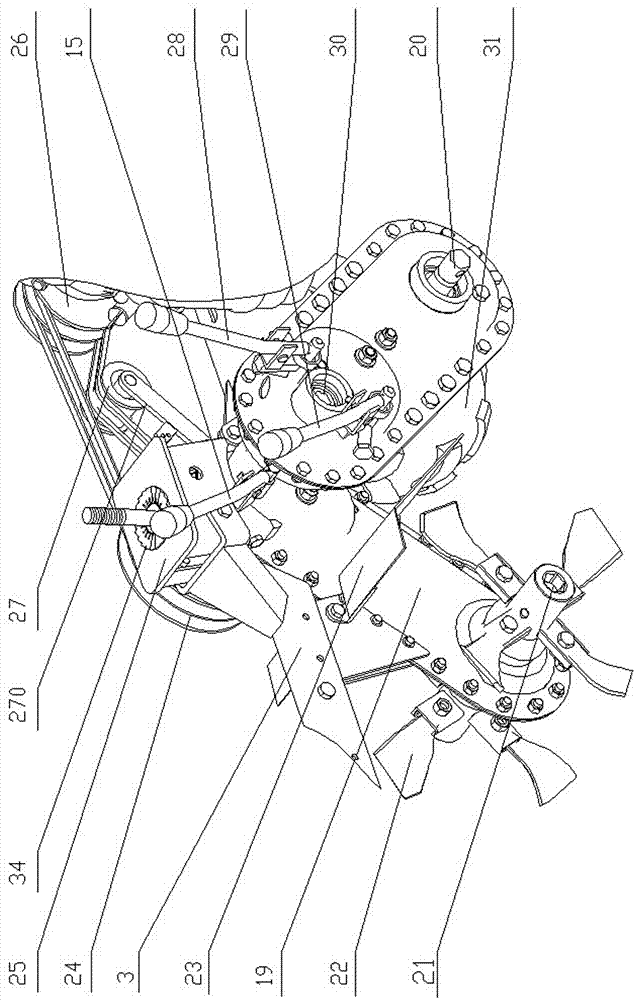

[0024] The following describes the specific implementation of the cultivator cultivator suitable for inter-row operations in the present invention in conjunction with the accompanying drawings.

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the cultivating soil cultivator suitable for inter-ridge operation of the present invention includes a frame device composed of a frame 1 and a support 3 fixed on the front of the frame 1, and also includes a power unit connected to the frame device, a soil cultivator devices, running gear and manipulating gear.

[0026] Described power unit comprises power machine 16, gearbox 19 that are fixed on the frame device, and power machine 16 is provided with driving wheel 26, and driven wheel 24 is coaxially connected with gearbox main shaft 30, between driving wheel 26 and driven wheel 24 Transmission connection; the gearbox 19 is provided with a ground wheel shaft 20 and a coulter shaft 21; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com