A soil cultivator with an improved spiral soil cultivating mechanism

A soil cultivator and screw technology, which is applied to agricultural machinery and tools, agricultural machinery equipment, shovels, etc., can solve the problems of crop leaf crushing, non-directional soil cultivation, etc., and achieve the effects of saving energy, reducing mechanical damage, and reducing crop damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

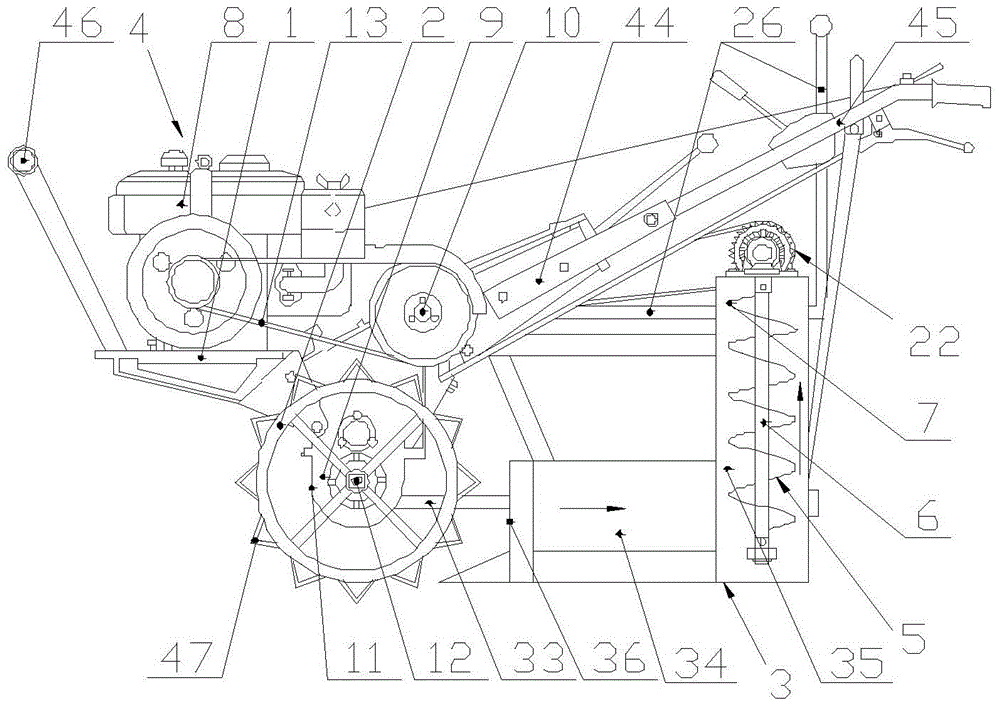

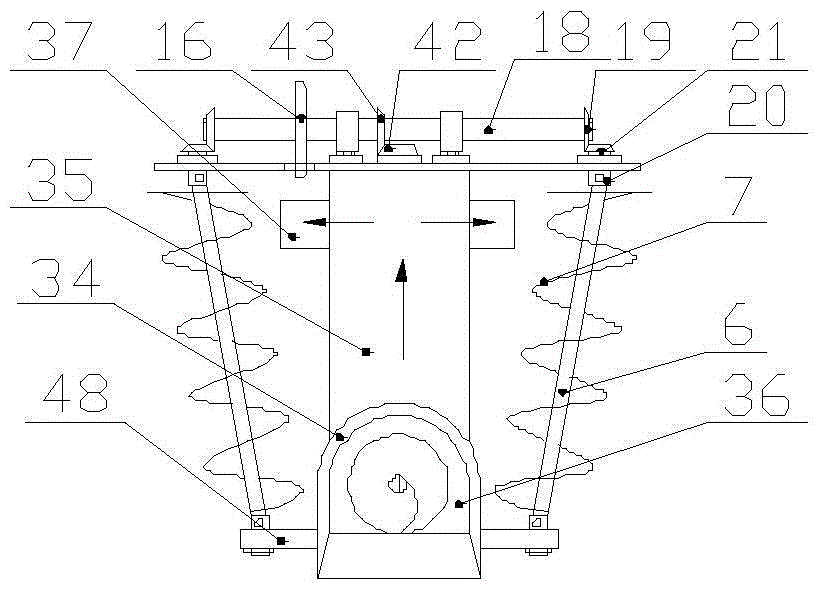

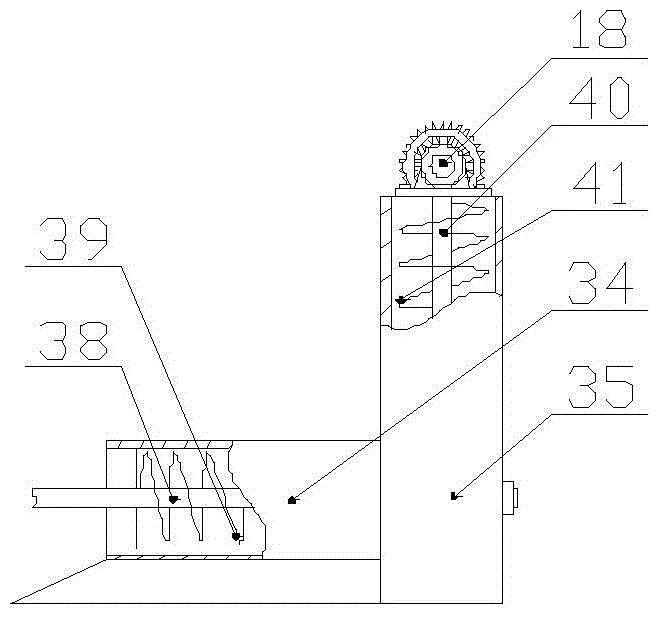

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0024] refer to Figure 1~5, a soil cultivating machine improved with a spiral soil cultivating mechanism, comprising: a frame 1 for installing various components, a wheel 2 installed at the bottom of the soil cultivating machine, a spiral soil cultivating mechanism 3 for realizing the soil cultivating function, and a driving device for providing power 4. The driving device 4 is respectively connected to the screw soil cultivation mechanism 3 and the wheel 2 in transmission. Both the driving device 4 and the screw soil cultivation mechanism 3 are installed on the frame 1 . A weeding device 5 for weeding is provided on the cultivator. The weeding device 5 includes at least one set of spiral weeding knives, each set of spiral weeding knives includes a first rotating rod 6 and a first helical blade 7, and the first helical blade 7 is helically wound around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com