Method for recycling and reusing stone slab waste

A waste recycling and stone slab technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as damage to the environment, huge burden, and difficulty in obtaining large-scale burial sites, so as to improve environmental protection benefits. , the effect of adding variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

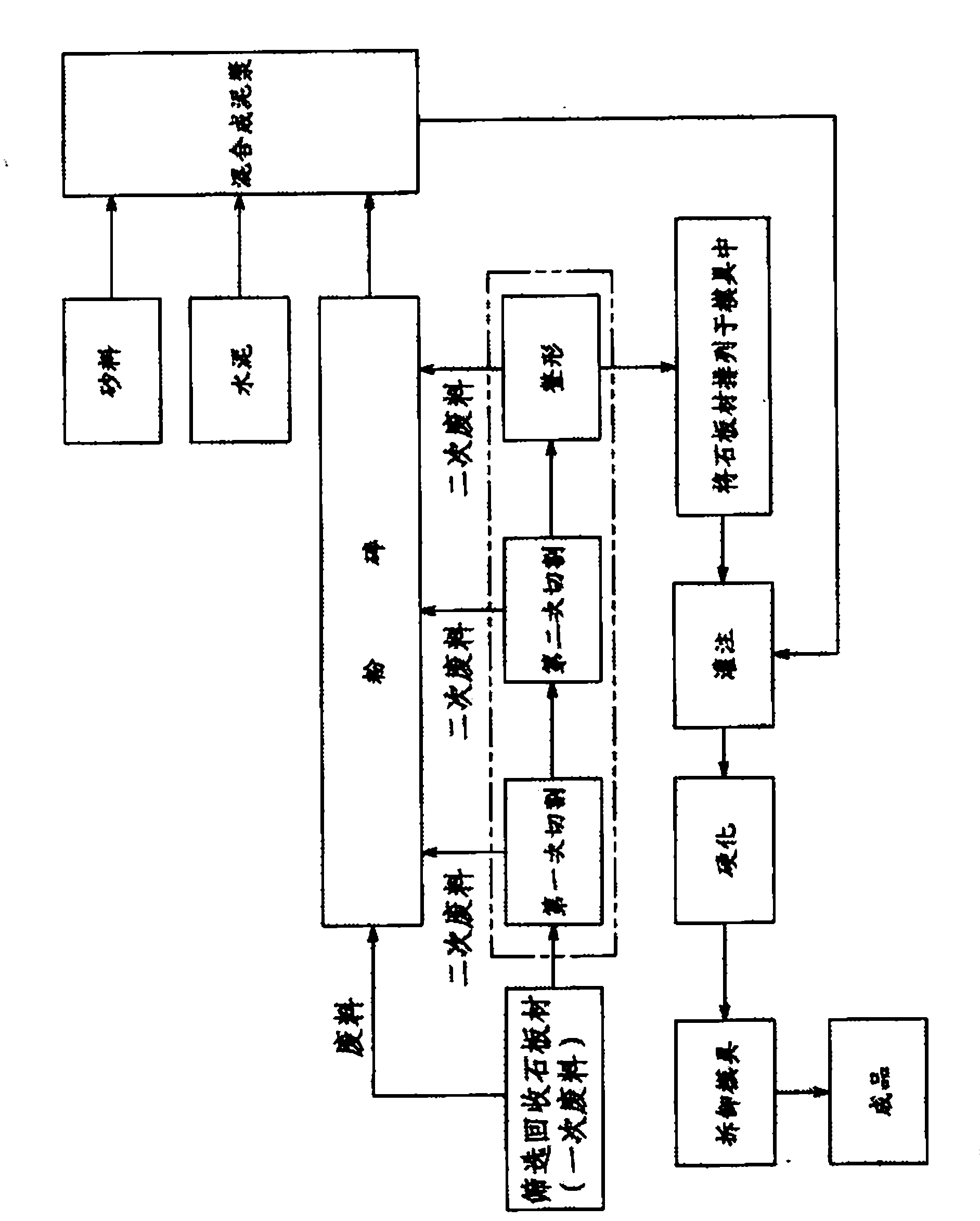

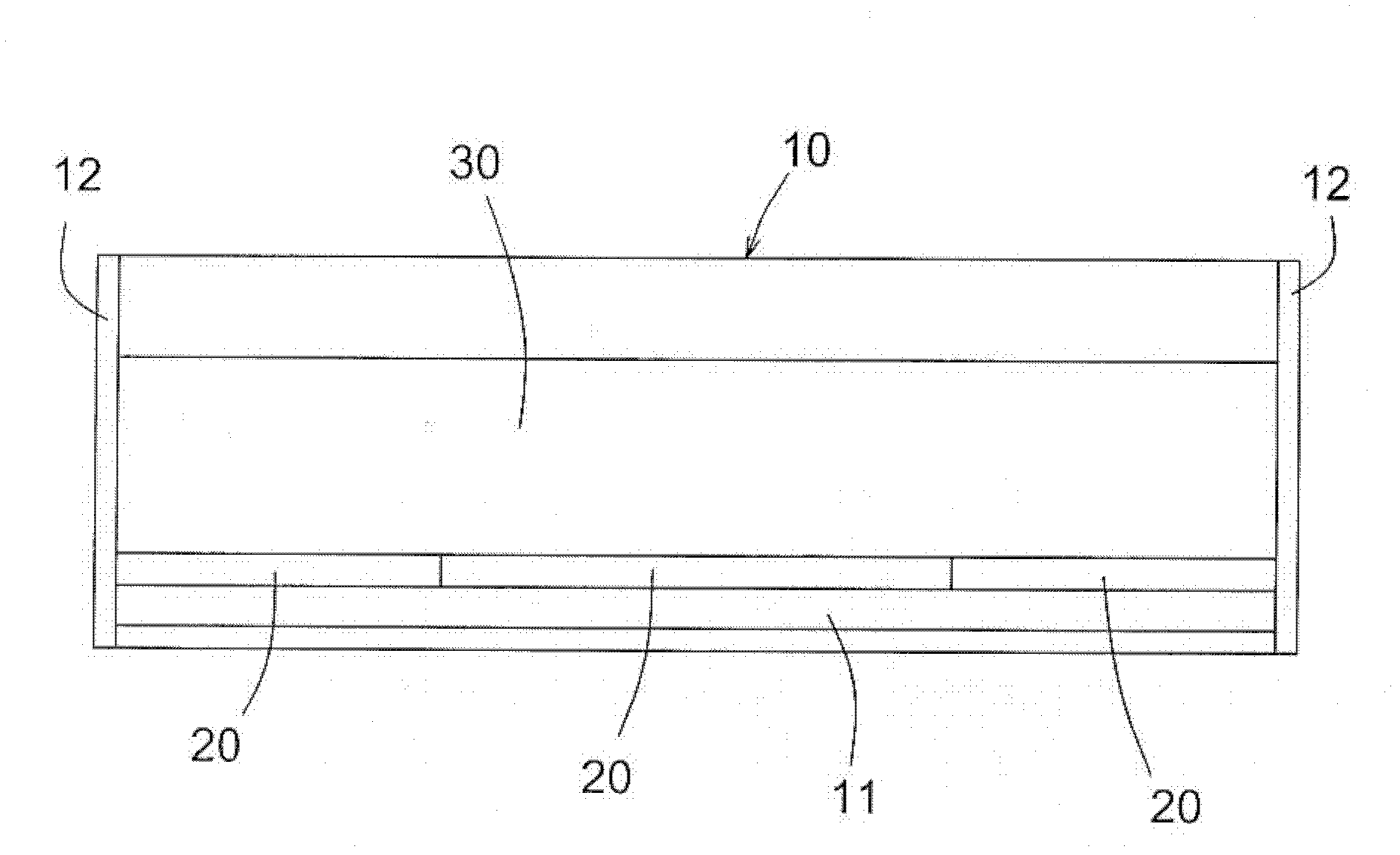

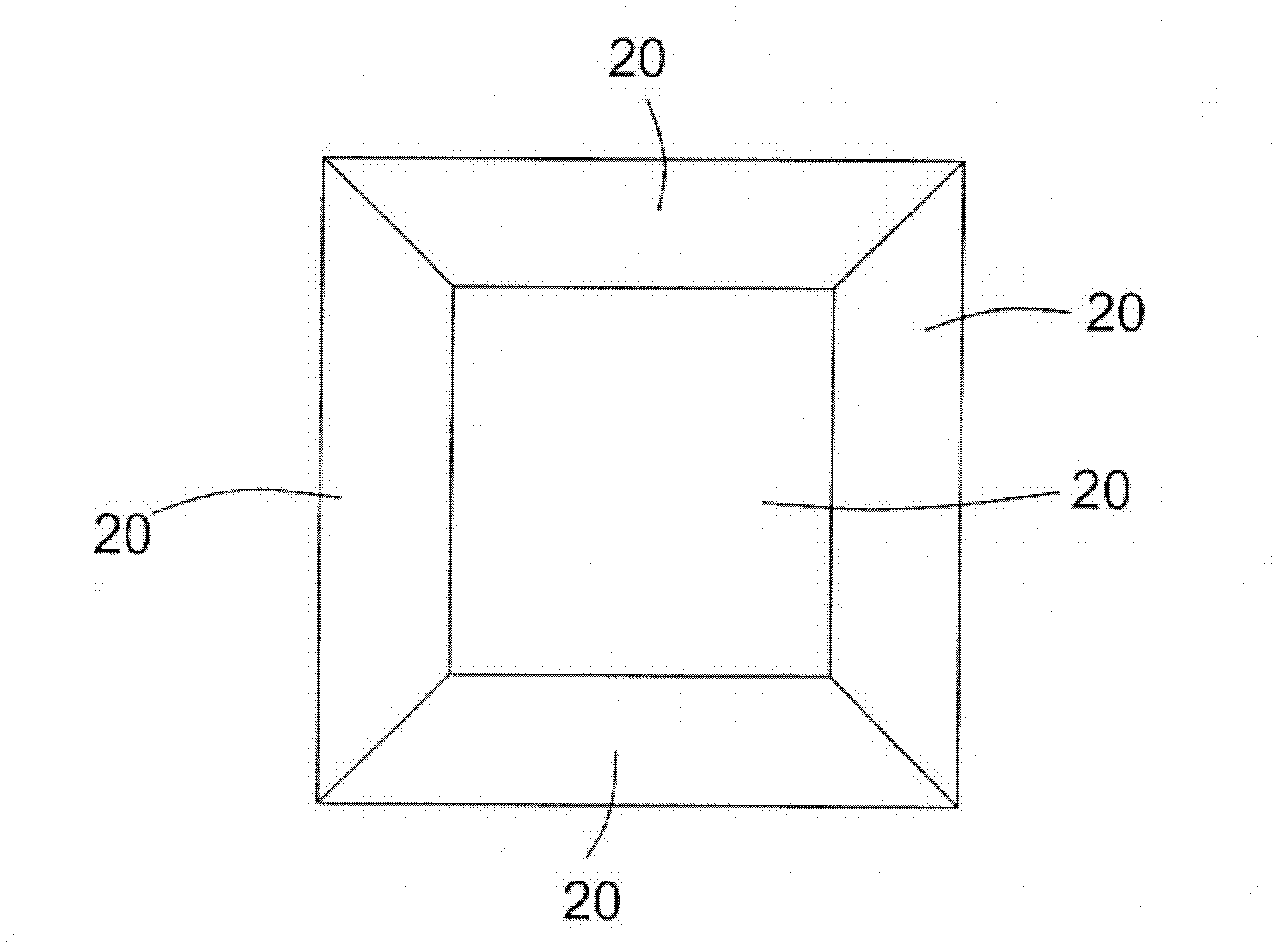

[0036] see figure 1 As shown, the present invention relates to a method for recycling and reusing stone slab waste, which is the "primary waste" formed by the remaining stone slab waste after cutting by the stone factory or the originally flawed stone slab waste, etc. The stone slabs obtained after cutting are placed in a mold, and the "secondary waste" that cannot be reused after cutting is crushed, mixed with an appropriate amount of cement, water and sand to form concrete, and the Concrete is poured into the mold covered with stone slabs. After hardening, the mold can be removed to obtain a large-area building material whose surface is composed of several stone slabs. In the above method, the present invention can fully utilize the recycled stone slabs , there is no cost to obtain raw materials, and the formed waste materials are all crushed to form fine gravel and then reused. In the manufacturing process, the amount of sand and gravel used can be reduced. In addition to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com