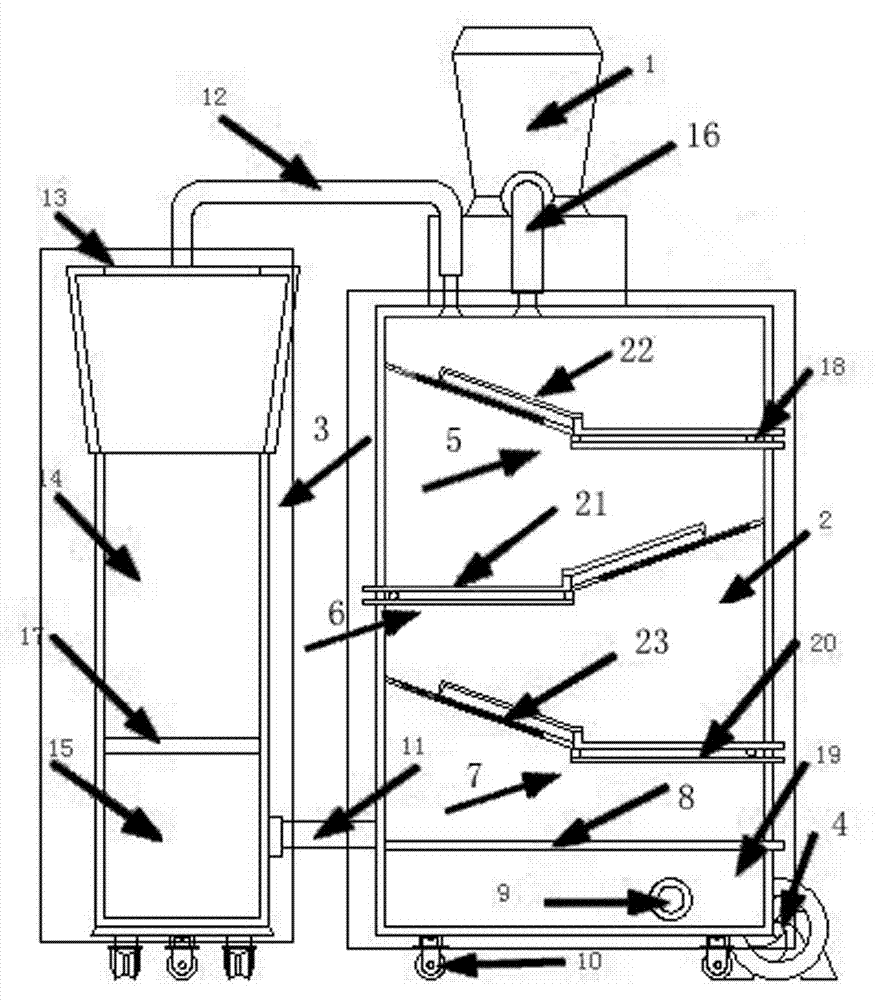

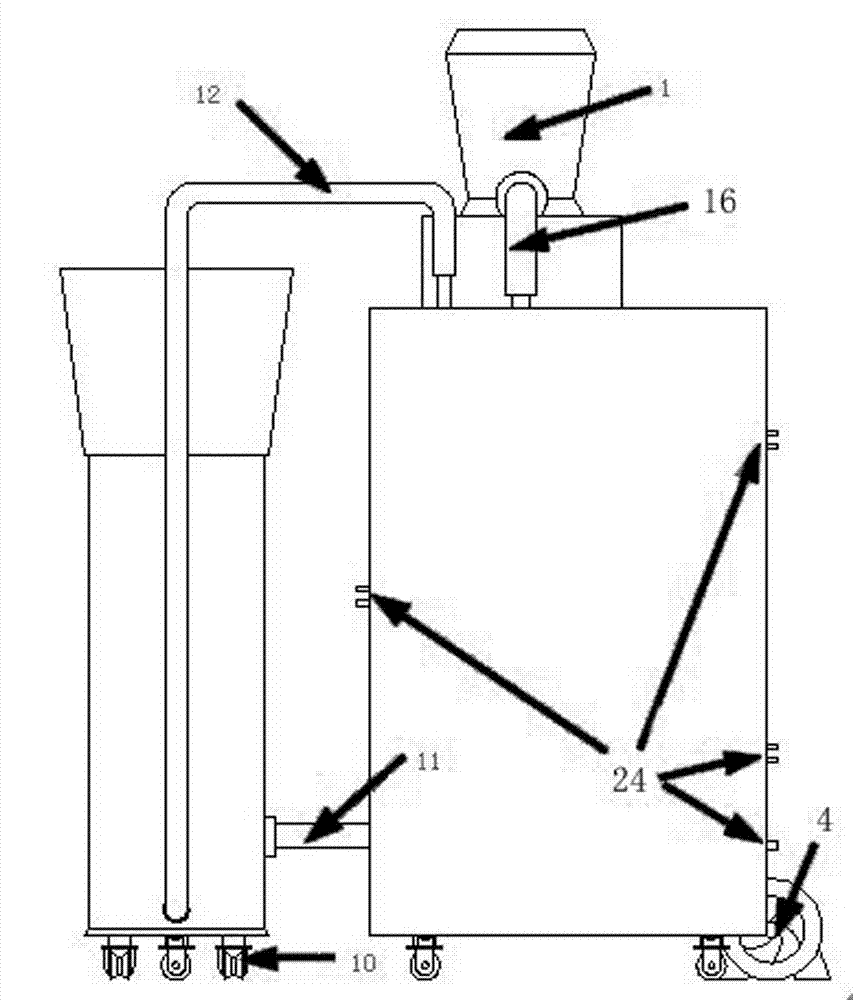

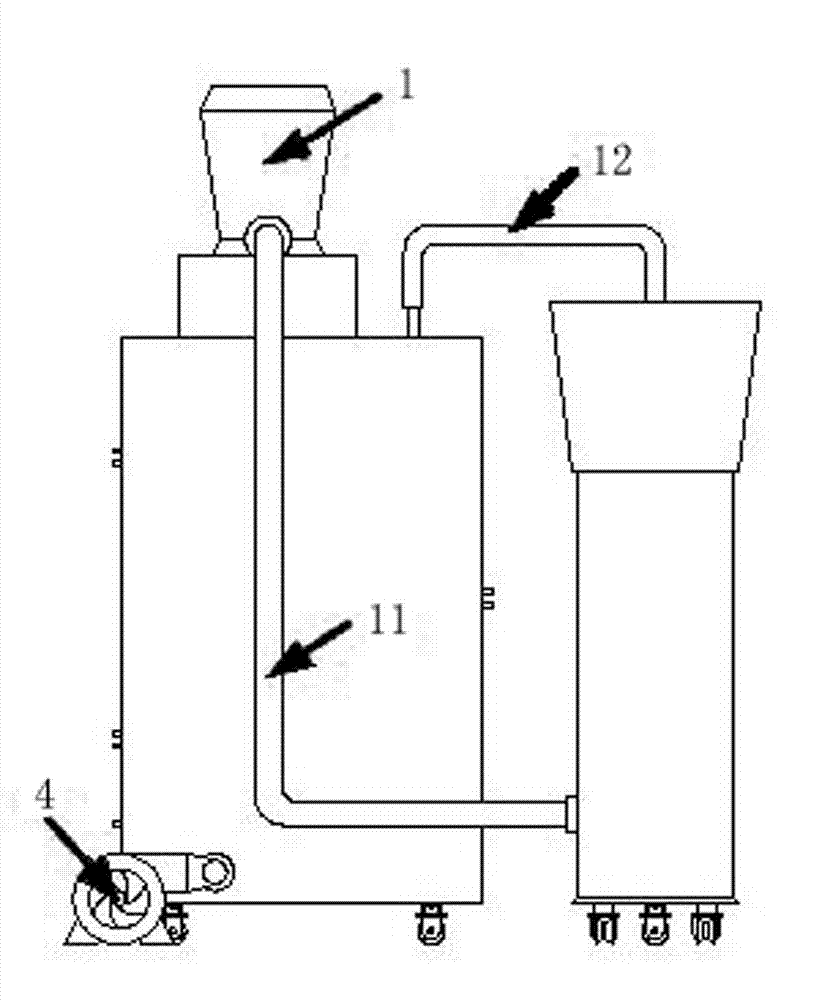

Biodegradable waste processor and method for producing mycoprotein by using same

A garbage disposer and biodegradation technology, applied in the field of environmental protection technology and biotechnology, can solve the problems of insufficient garbage grinding, cumbersome operation, easy to burn out switches or motors, etc., to save manpower, maintain environmental sanitation, and eliminate kitchen waste the harmful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046]Take 0.25kg of banana peels, orange peels, melon seed peels, leftover vegetable leaves, leftovers, waste paper and 0.1kg of Rhizopus niger and Saccharomyces cerevisiae (the ratio of the two is 1:1) and mix and crush them, and send the solids into Garbage fermentation system, ventilated, temperature controlled at 25°C; waste liquid produced during the garbage crushing process and leachate produced during the fermentation process enter the landfill leachate recovery and reuse system, adjust the pH value to 4, ventilate and aerate, and carry out fermentation treatment , to obtain the culture medium. The culture solution is pumped to the rubbish crushing system, and crushed together with the aforementioned rubbish, thus completing the recycling of the bacteria. After culturing for 16 hours, collect the culture and dry it to obtain bacterial protein. The protein content of the bacterial protein can reach more than 30%, which can be used as a feed additive.

Embodiment 2

[0048] Take 0.25kg of banana peels, orange peels, melon seed peels, leftover vegetable leaves, leftovers, waste paper and 0.1kg of Rhizopus niger and Saccharomyces cerevisiae (the ratio of the two is 1:1) and mix and crush them, and send the solids into Garbage fermentation system, ventilation, temperature control at 30°C; waste liquid generated during the garbage crushing process and leachate generated during the fermentation process enter the landfill leachate recovery and reuse system, adjust the pH value to 5, ventilate and aerate, and carry out fermentation treatment , to obtain the culture medium. The culture solution is pumped to the garbage crushing system, and crushed together with the aforementioned garbage, thus completing the recycling of the bacteria. After culturing for 20 hours, the culture is collected and dried to obtain bacterial protein. The protein content of the bacterial protein can reach more than 30%, which can be used as a feed additive.

Embodiment 3

[0050] Take 0.25kg of banana peels, orange peels, melon seed peels, leftover vegetable leaves, leftovers, waste paper and 0.1kg of Rhizopus niger and Saccharomyces cerevisiae (the ratio of the two is 1:1) and mix and crush them, and send the solids into Garbage fermentation system, ventilation, temperature control at 35°C; waste liquid generated during the garbage crushing process and leachate generated during the fermentation process enter the landfill leachate recovery and reuse system, adjust the pH value to 6, ventilate and aerate, and carry out fermentation treatment , to obtain the culture medium. The culture solution is pumped to the garbage crushing system, and crushed together with the aforementioned garbage, thus completing the recycling of the bacteria. After culturing for 24 hours, the culture is collected and dried to obtain bacterial protein. The protein content of the bacterial protein can reach more than 30%, which can be used as a feed additive.

[0051] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com