Hauling-up device for replacing pin insulator and replacing method

The technology of a lifting device and a replacement method is applied in the direction of lifting device, overhead line/cable equipment, etc., which can solve the problems of limited working range of insulated needle bottles and difficulty in electrified replacement of damaged needle bottles, so as to achieve the effect of improving the working scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

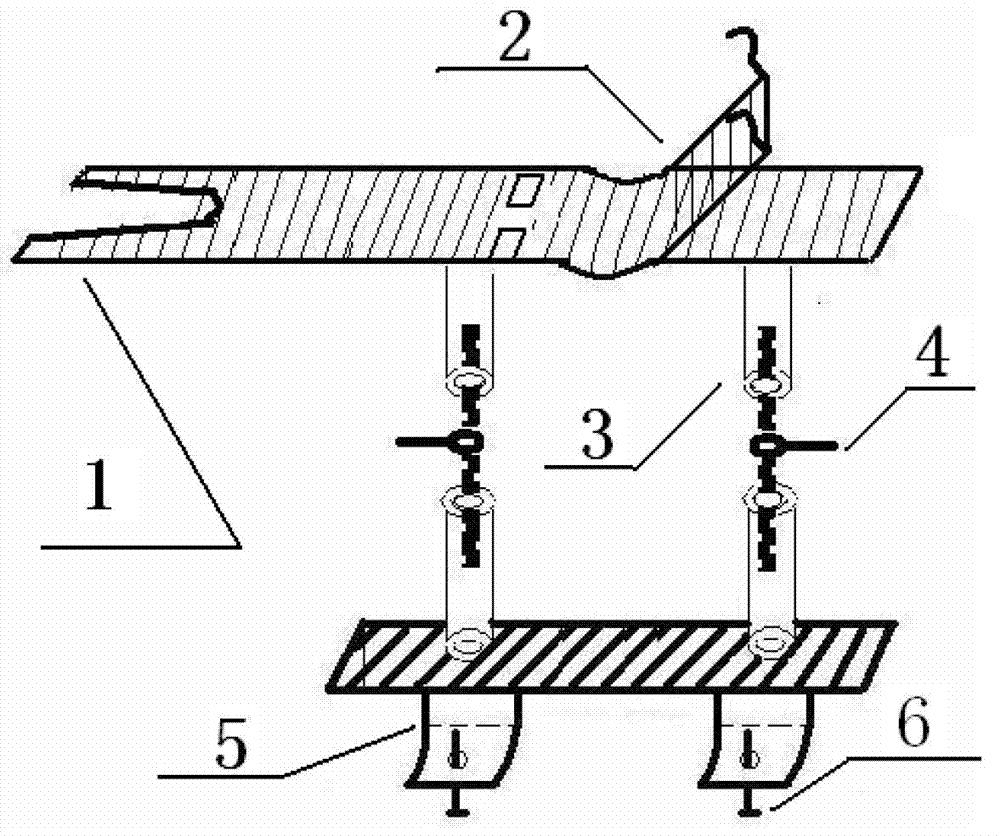

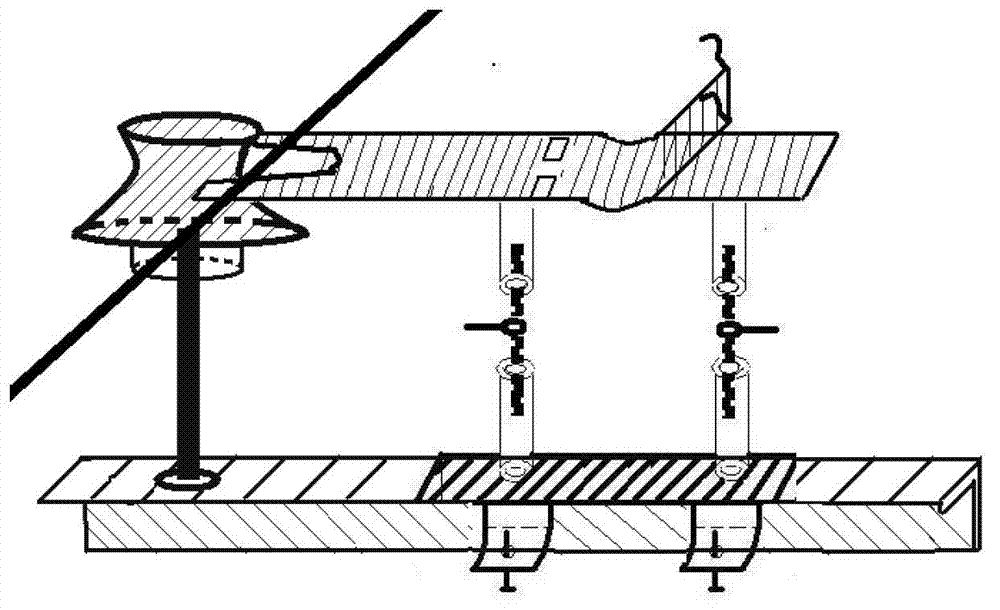

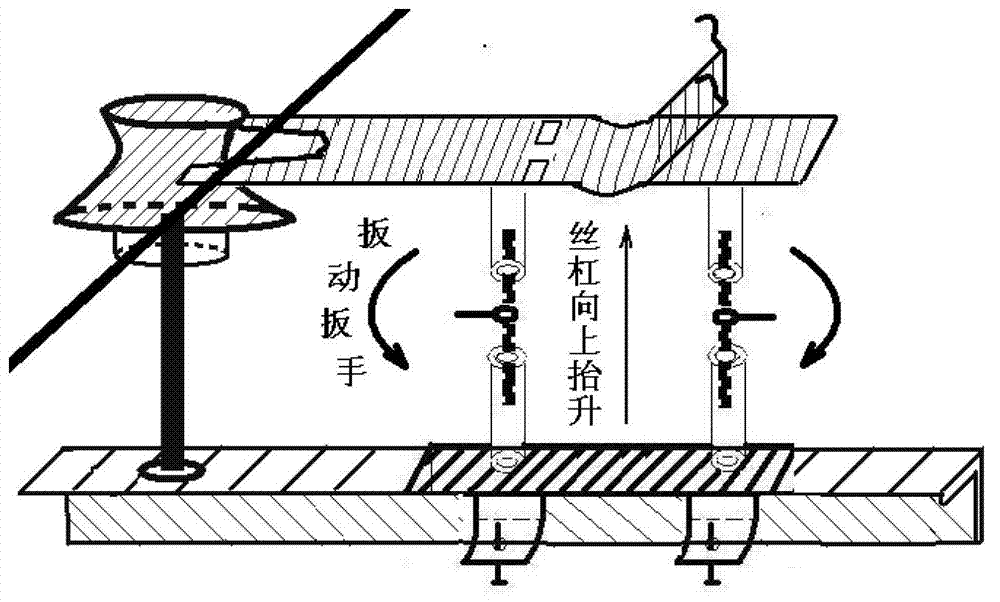

[0026] see figure 1 , a lifting device for replacing insulating needle bottles, including an insulating support with an insulating support wire opening 1 at one end, and a wire clamping slot and a matching wire clamping slot cover 2 on the insulating bracket; the insulating bracket passes through The lifting rod 3 is connected to the insulating base plate, and a fixing device 5 for fixing the cross arm is provided under the insulating base plate; the lifting rod includes an upper sleeve connected by a rod with positive and negative threads at both ends and The lower sleeve has positive and negative threaded rods at both ends and is connected with the ratchet wrench 4 .

[0027] Specifically, grooves are arranged next to the wire clamping slot, and hooks matching the grooves are provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com