Discharge valve assembly for two-stroke engine, provided with cooling, non-contacting seal and self-cleaning

A technology of valve components and exhaust valves, applied in engine components, engine control, combustion engines, etc., can solve environmental pollution and other problems, and achieve the effect of eliminating thermal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

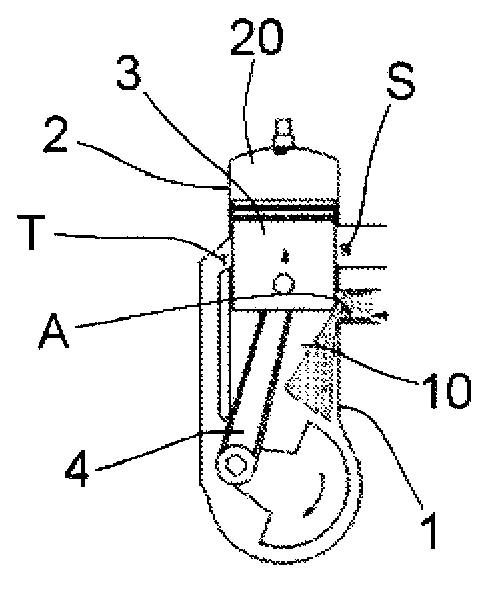

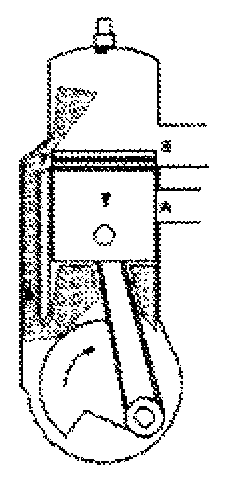

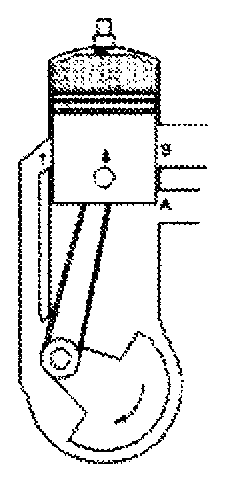

[0046] With reference to the aforementioned figures, the exhaust valve assembly of the present invention is described, generally indicated by the reference numeral (100).

[0047] figure 2 A two-stroke internal combustion engine (200) is shown coupled to an exhaust box (300). Parts of an internal combustion engine (200) are used for Figure 1A~1F The same reference numerals are used in the description of , and thus their detailed descriptions are omitted.

[0048]The exhaust valve assembly (100) is installed downstream of the exhaust port (S) of the cylinder (2) of the engine. The valve assembly (100) can be integrally formed with the casing of the engine (200), or as an independent component, arranged between the casing of the engine (200) and the exhaust box (300).

[0049] refer to image 3 with Figure 4 , the valve assembly (100) includes a housing (5) and a valve (7) rotatably mounted on the housing (5).

[0050] refer to Figure 5 , the valve (7) is substantially...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap