Leak detector

A leak detection and sensor technology that can solve problems such as affecting optical properties and fiber deformation by detecting the presence of fluids, instruments, measuring devices, etc. at the leak point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

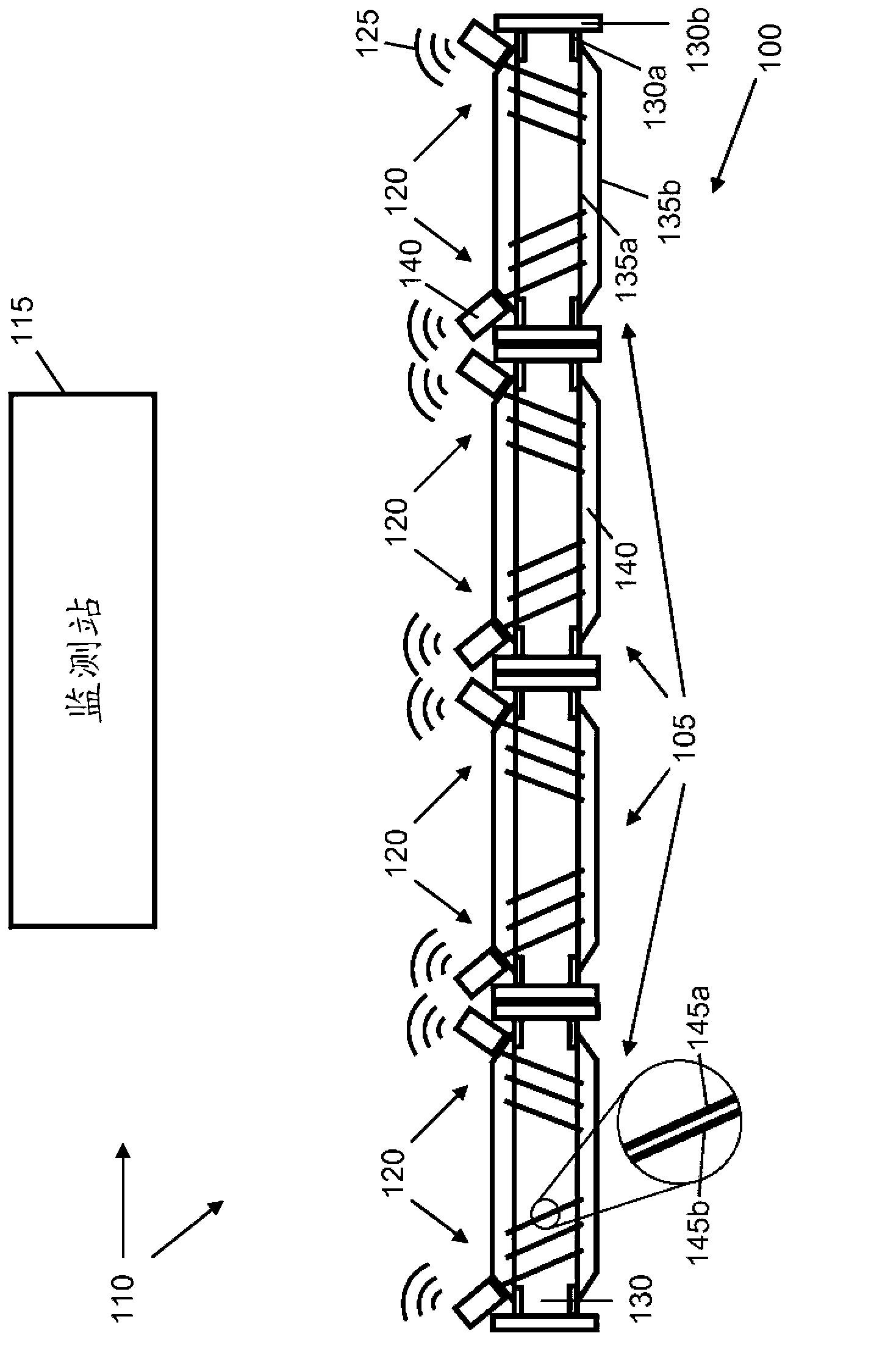

[0022] refer to figure 1 , the underwater hose 100 is formed from connected hose sections 105 and in use is submerged underwater. The leak detection system 110 consists of a monitoring station 115 and a plurality of sensor devices 120 , two mounted to each hose section 105 of the hose 100 . Each sensor device 120 independently communicates with monitoring station 115 via transmitted sonar signals 125 . In other embodiments, the hose 100 is not submerged (eg, it floats on the surface of the water), and the transmitted signal 125 is an electromagnetic signal.

[0023] The hose sections 105 are connected to each other at their ends to form the hose 100 . A hose end fitting 130 is located at each end of the individual hose sections 105 by which the hose sections 105 are connected together. Each end fitting 130 consists of a tubular portion 130a connected to a larger diameter flange 130b. A hole is formed through the flange 130b through which the respective end fittings 130 of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap