Clamping device

A technology of clamping device and receiving sleeve, which is applied in the direction of portable mobile devices, accessories of tool holders, chucks, etc., and can solve problems such as receivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

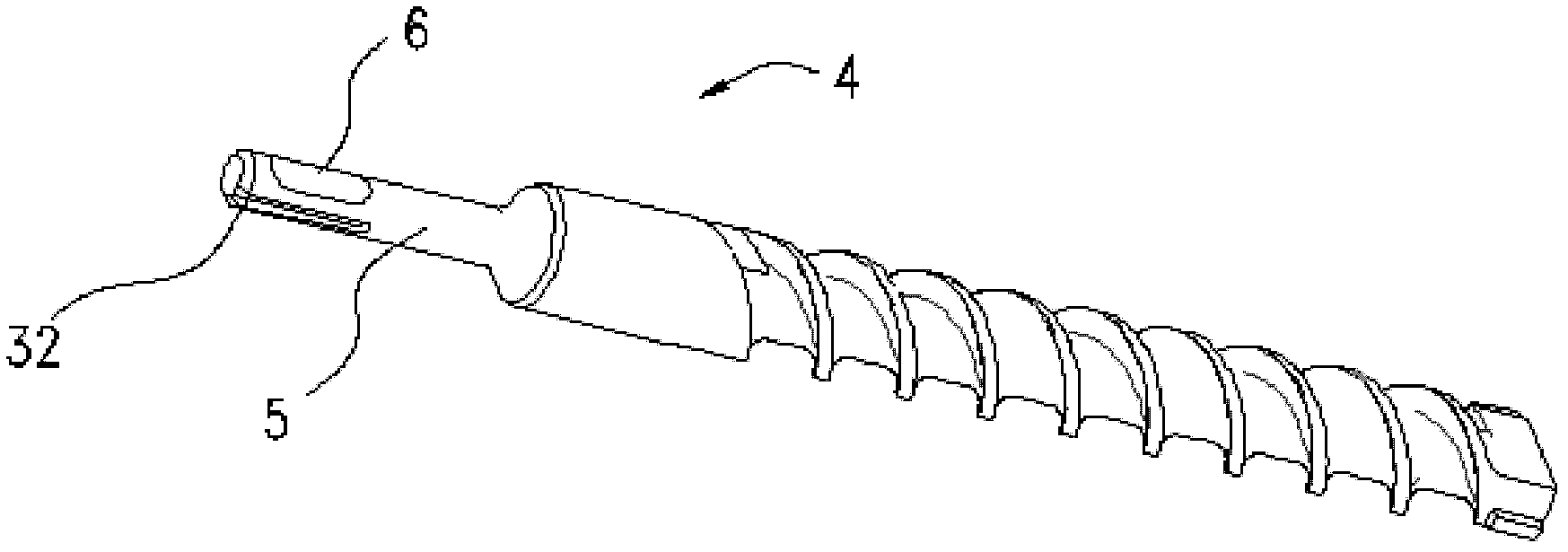

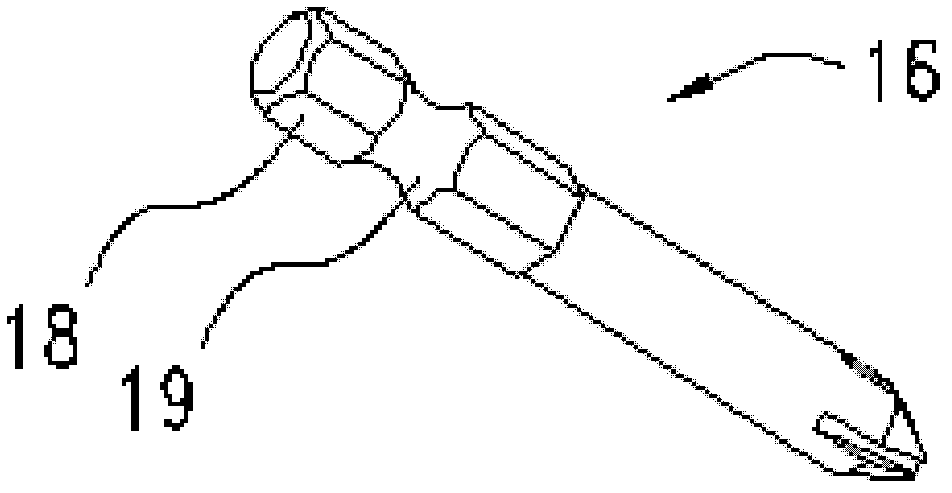

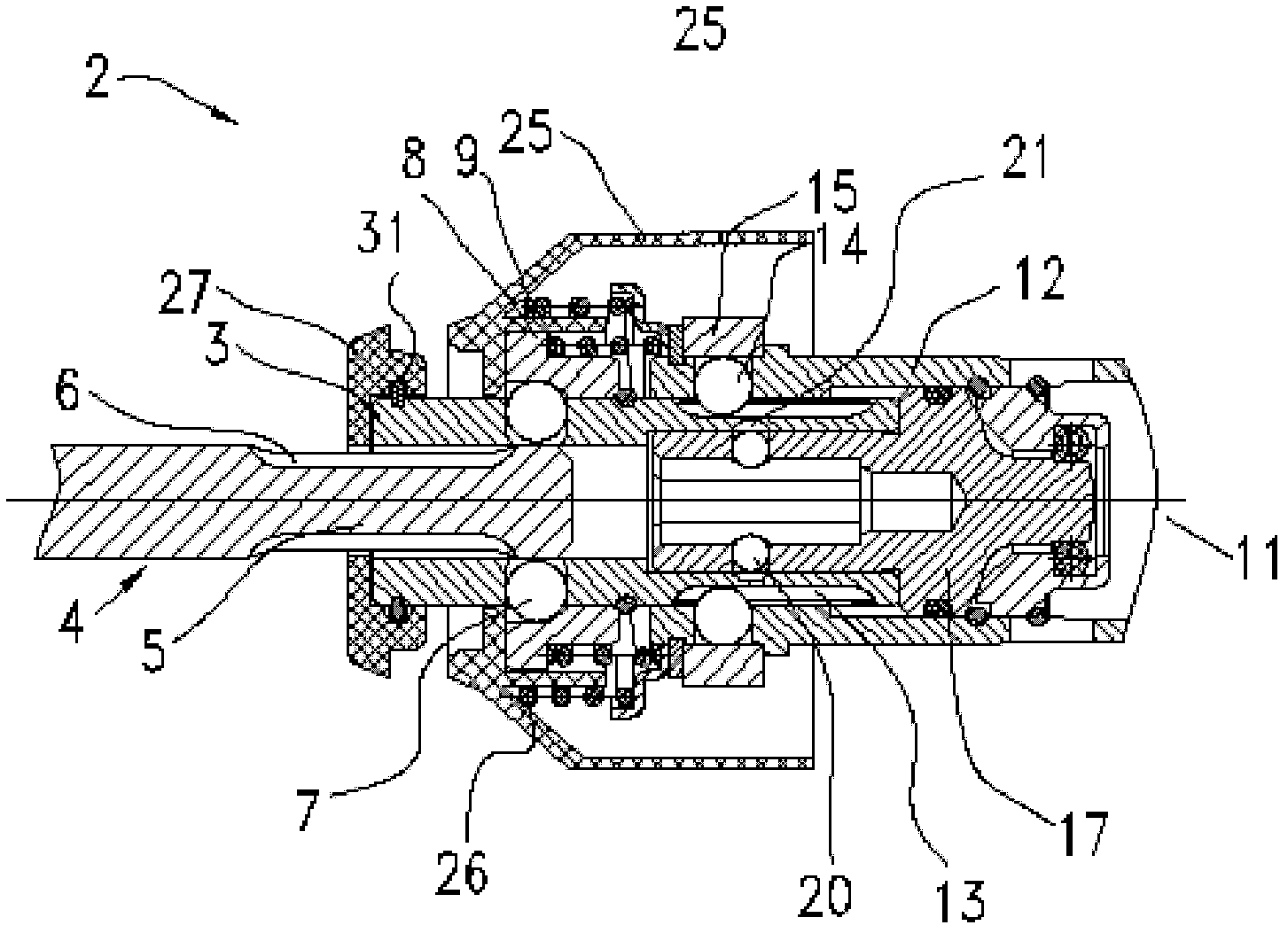

[0019] together with reference Figure 1 to Figure 12 As shown, the clamping device of the present invention is applied to an electric tool with a hammer tube. The clamping device 2 includes: a first receiving sleeve 3 for accommodating the first working head. A working handle that is matched with the receiving sleeve 3; a second receiving sleeve 17 is used to accommodate the second working head, and the second working head has a working handle that cooperates with the second receiving sleeve 17; wherein the first working handle has a difference In terms of the shape of the second working handle, for example: the first receiving sleeve 3 can be plugged and fitted with the SDS-Plus type working head 4, and the second receiving sleeve 17 can be plugged and fitted with the HEX type working head 16. The first receiving sleeve 3 and the hammer tube 12 in the tool holder 1 are connected to each other through the first transmission structure, and the first receiving sleeve 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com