Thin plate workpiece feeding mechanism

A technology of feeding mechanism and workpiece, applied in thin material handling, object supply, pile separation, etc., can solve the problems of low work efficiency of workers, high production cost of enterprises, inconvenient operation of workers, etc., to achieve simple maintenance work, improve work efficiency, Simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

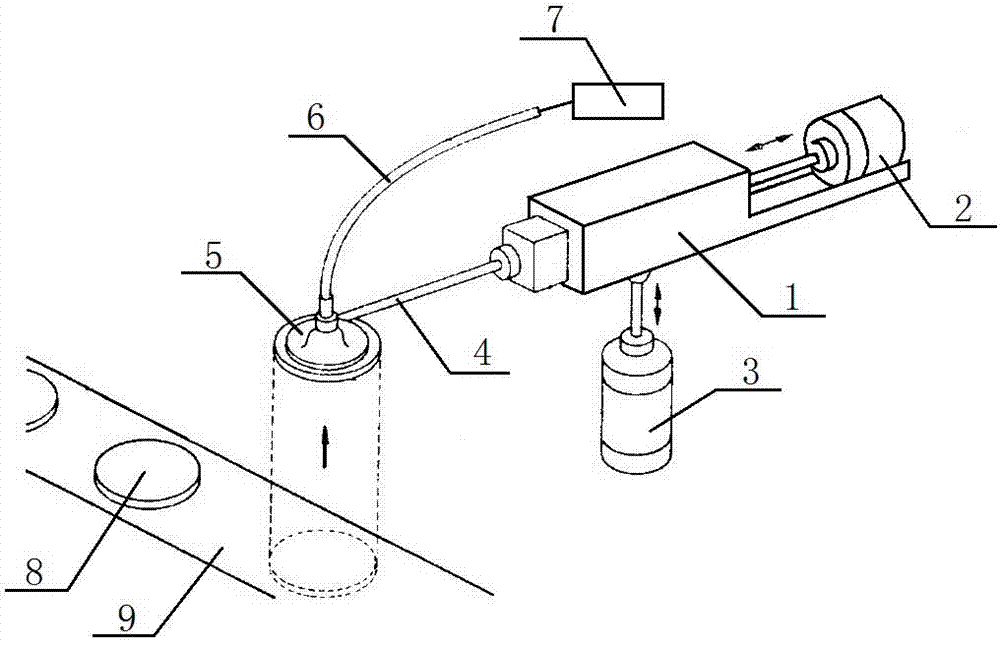

[0010] like figure 1 As shown, the present invention provides a thin-plate workpiece feeding mechanism, including a cylinder mounting block 1 and a workpiece table 9 on which a thin-plate workpiece 8 is placed. The rear end of the cylinder mounting block 1 is connected to the horizontal cylinder 2, the lower end is connected to the vertical cylinder 3, and the front end is passed through the connecting rod. 4 is connected to the suction cup 5, the suction cup 5 is connected to the vacuum device 7 through the hose 6, and the suction cup 5 and the thin plate workpiece 8 are both circular.

[0011] In this embodiment, the arrangement of the horizontal cylinder 2 and the vertical cylinder 3 realizes the adjustment of the position of the suction cup 5 and facilitates the transportation of the thin plate workpiece 8 .

[0012] In addition, both the suction cup 5 and the thin-plate workpiece 8 are circular, mainly considering the convenience of sucking the thin-plate workpiece 8 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com