Horizontal rotating suspension bracket for grab bucket

A technology of horizontal rotation and hanger, which is applied in earth mover/excavator, construction, etc. It can solve the problems of complicated synchronous coordination control, high maintenance cost, and large power transmission loss, etc., and achieves simple structure, stable rotation, and avoids The effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated below by specific examples.

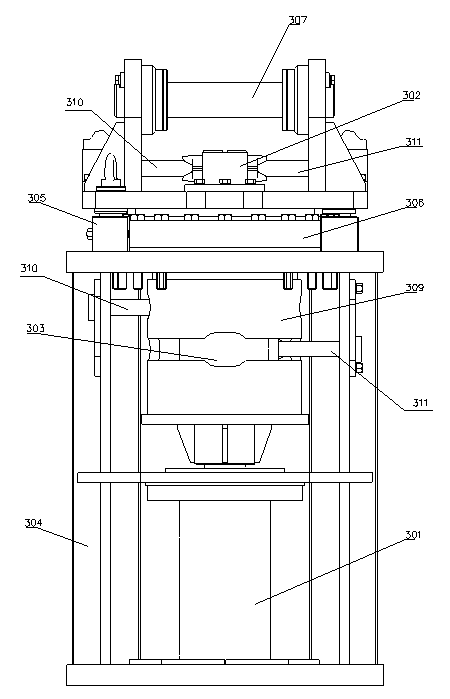

[0019] Such as figure 1 As shown, a horizontally rotating hanger for a grab bucket includes a frame 304, a hanger 307, a slewing bearing 306 whose outer ring is fixedly connected to the top of the frame 304, and the inner ring is fixedly connected to the hanger 307, and is arranged in the frame 304. The driving cylinder 301, the torsion transmission frame 309 which is arranged in the frame 304 and fixedly connected with the drive cylinder 301, and the top of the torsion transmission frame 309 is fixed in the top of the frame 304.

[0020] The horizontally rotating hanger for the grab also includes an oil seal sleeve 303 and a mandrel 302; the mandrel 302 is fixed at the center of the hanger 307 and is set in the torsion transmission frame 309 after passing through the inner ring of the slewing bearing 306 , the oil seal sleeve 303 is set on the mandrel 302 .

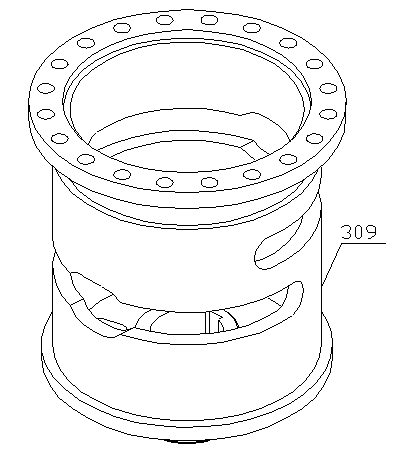

[0021] Such as figure 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com