Concentricity detection equipment

A technology for testing equipment and concentricity, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of instability, deviation, and low measurement efficiency of measurement results, and achieve stable rotation, simple operation, and high detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

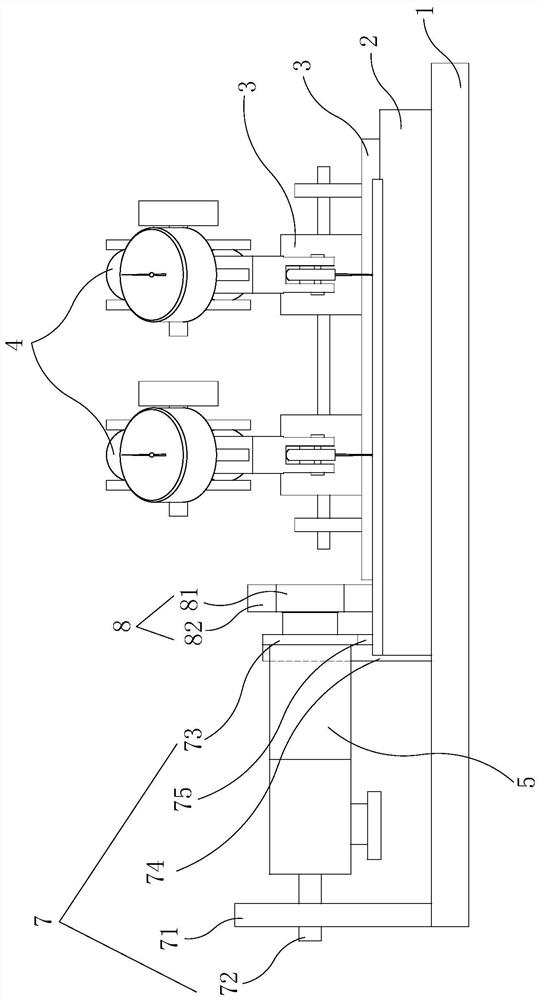

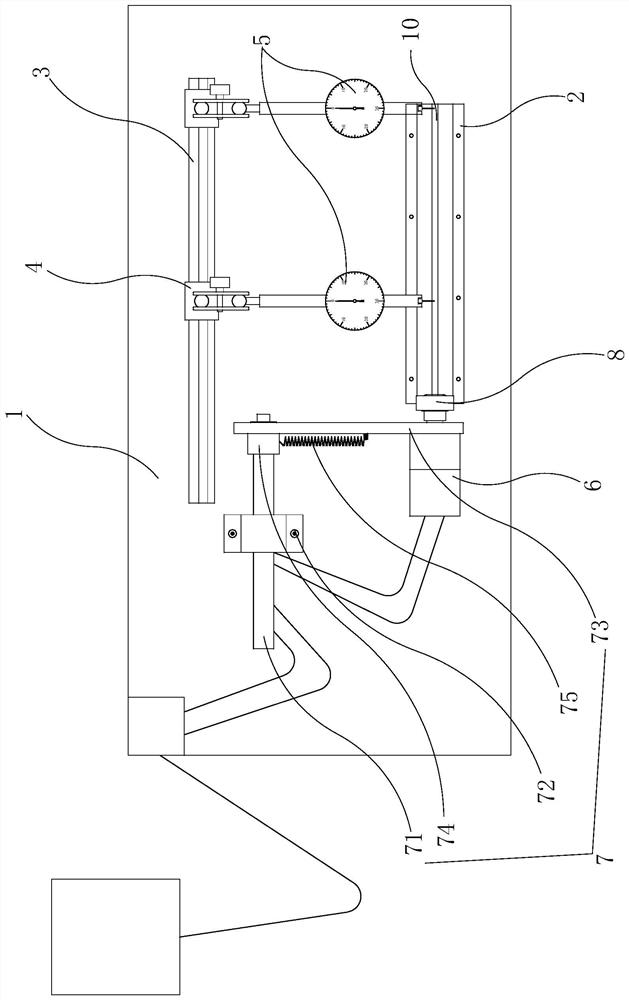

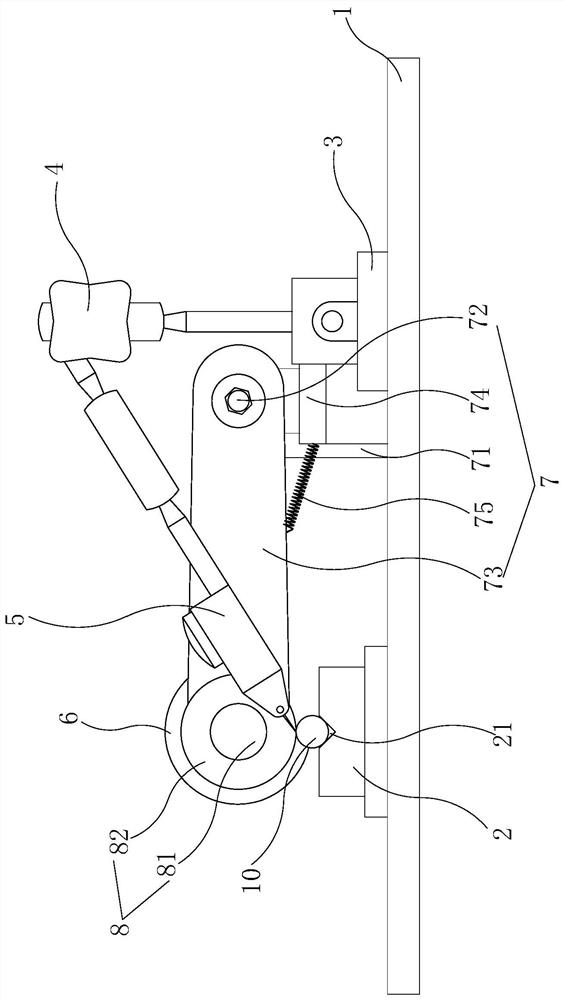

[0015] like Figure 1-Figure 3 As shown, the present invention is a kind of concentricity detection equipment, comprises machine platform 1, support frame 2, guide rail 3, dial gauge frame 4, dial gauge 5, motor 6, motor frame 7, guide wheel 8.

[0016] The support frame 2 and the guide rail 3 are all installed on the machine platform 1 and the support frame 2 is parallel to the guide rail 3, the dial indicator frame 4 can be moved and fixed on the guide rail 3, and one end of the dial indicator 5 is fixed on the dial indicator The free end of submeter frame 4, the other end of dial gauge 5 stretches to material rack 2, and the top surface of material rack 2 is provided with product placement 21, and this product placement position 21 is a V-shaped groove. The bottom of described motor frame 7 is installed on the machine platform 1, and motor 6 is fixedly installed on the free end of motor frame 7, and the output shaft of motor 6 is installed with the guide wheel 8 that is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com