Rotating type belt taking-up and paying-off mechanism

A belt retractable and rotating technology, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of unbalanced force on the turret, and achieve the effects of stable rotation, reasonable layout, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

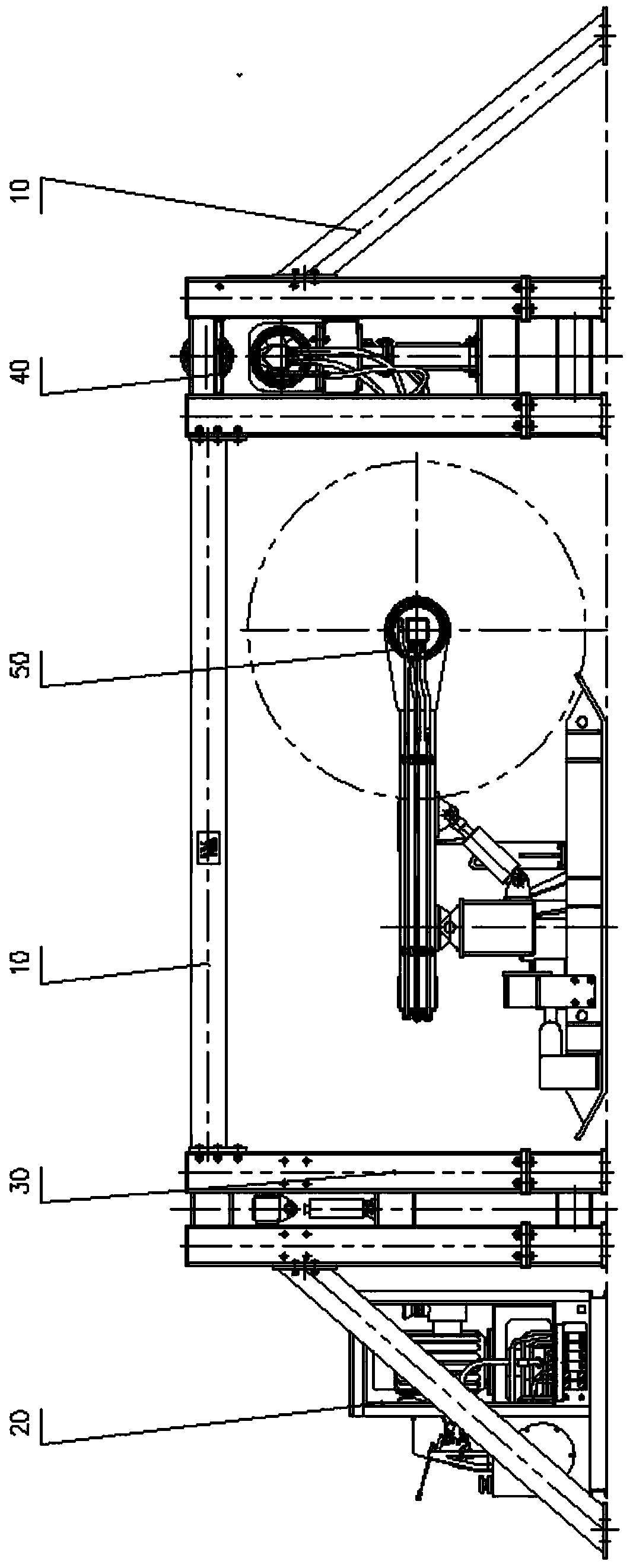

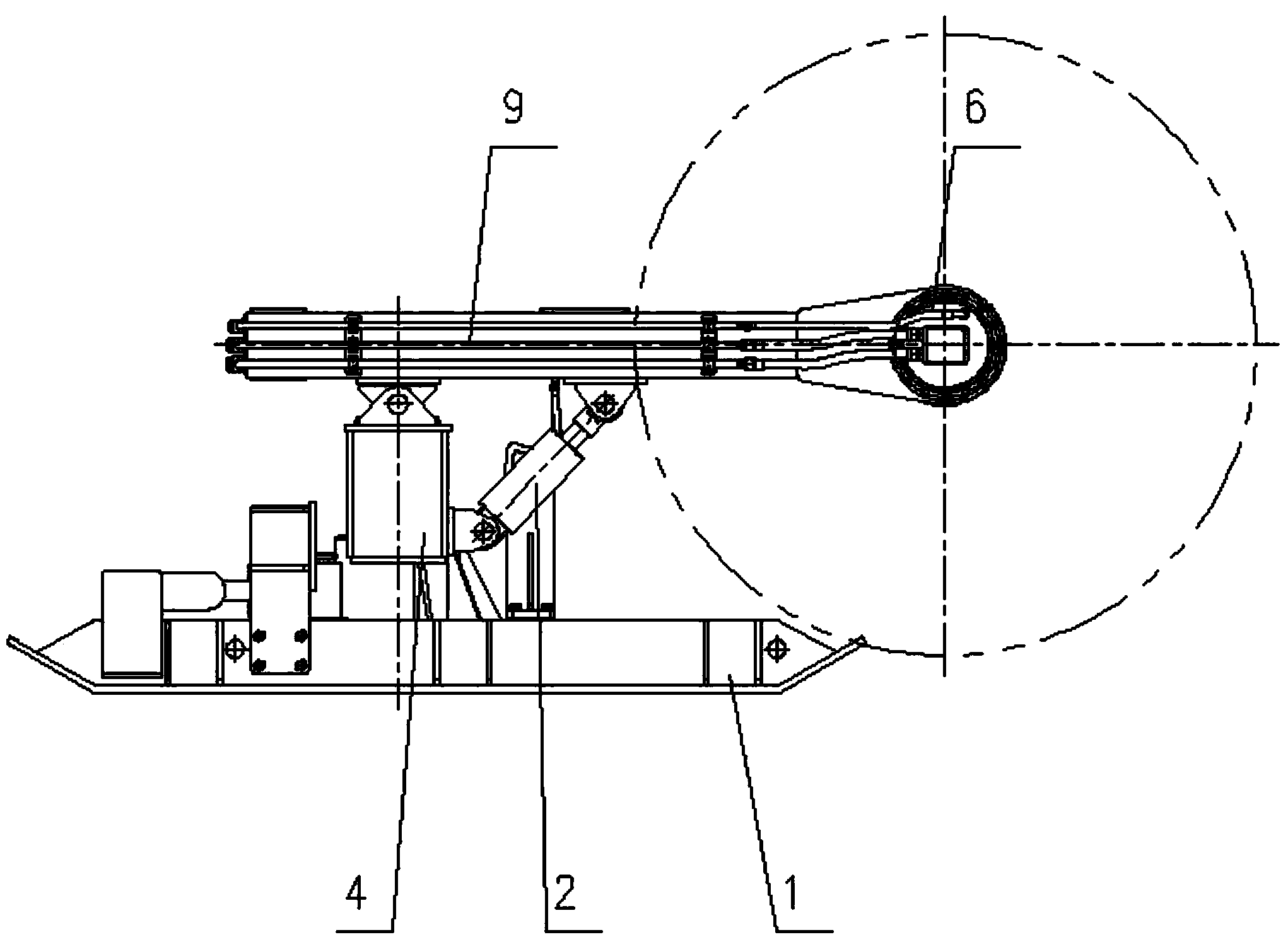

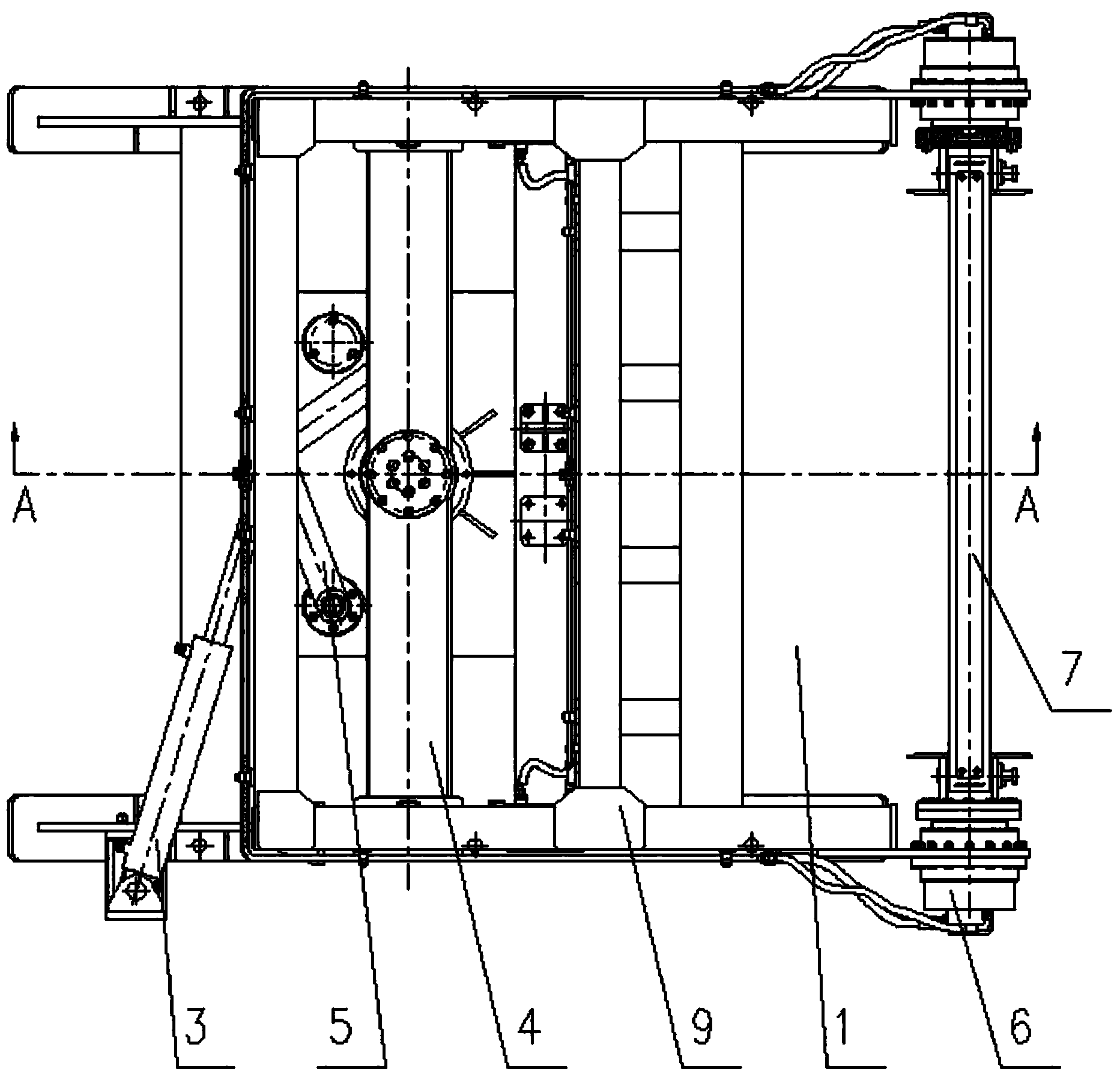

[0030] like Figure 2 to Figure 4 As shown, a rotary retractable belt mechanism includes a base 1, a turret 4 and a cantilever 9, the base 1 is provided with a vertical shaft 1.1, the turret 4 is set on the vertical shaft 1.1 and is connected with the vertical shaft 1.1 through a bearing, the cantilever 9 The bottom has three hinge points, one of which is hinged with the top of the turret 4 through a pin shaft, and the other two hinge points are hinged with the sides of the turret 4 through two lifting hydraulic cylinders 2, and the head of the cantilever 9 is connected There is a detachable take-up mandrel 7, the take-up mandrel 7 is driven to rotate by a hydraulic motor 6 located on its side, the tail of the base 1 is provided with a rotating hydraulic cylinder 3, and the lower side of the turret 4 is connected with a link mechanism 5, which is connected to The rod mechanism 5 is composed of two connecting rods, the two connecting rods are jointly hinged with the piston rod ...

Embodiment 2

[0038] like Figures 5 to 7 As shown, the second embodiment is basically the same as the first embodiment, except that an anti-roll deflection guide device 8 is provided on the inner side of the cantilever 9 .

[0039] When the hydraulic motor 6 drives the take-up mandrel 7 to start take-up, the anti-roll deflection guide device 8 starts to work, and the linear speeds of the guides at different positions and the take-up at different positions cooperate with each other, so that both ends of the rolled-out belt roll are neat And tight inside.

[0040] The anti-roll deflection guide device 8 can adopt two structural forms, wherein one anti-roll deflection guide device 8 includes a guide shaft connected to the inside of the cantilever 9 and several bearings sleeved outside the guide shaft and connected in series.

[0041] Another anti-roll deflection guide device 8 includes a guide shaft connected to the inside of the cantilever 9 and several nylon sleeves connected in series out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com