Binding construction method of steel pipe column ring beam reinforcing bars

A technology of steel bar binding and construction method, applied in construction, building structure, processing of building materials, etc., can solve the problems of steel bar damage, difficult to restore to its original state, and difficult construction, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

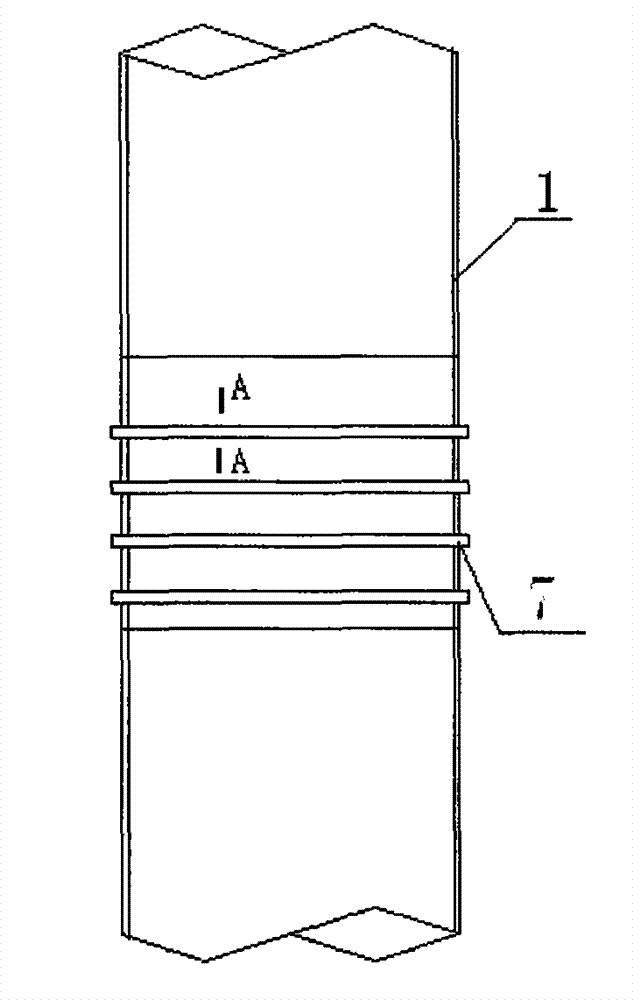

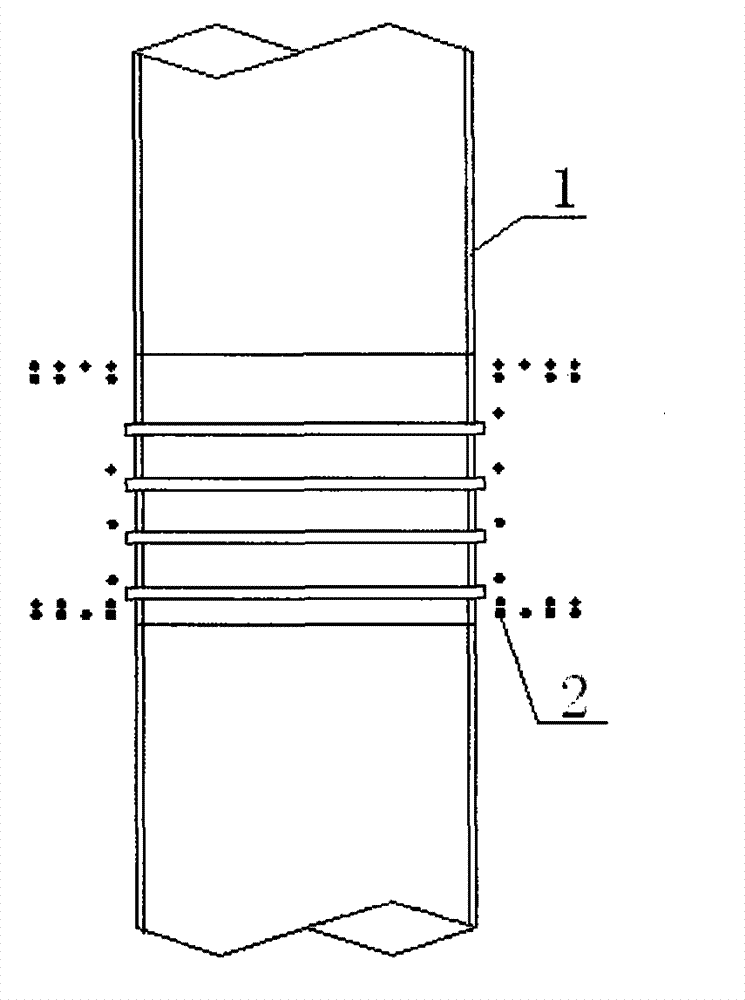

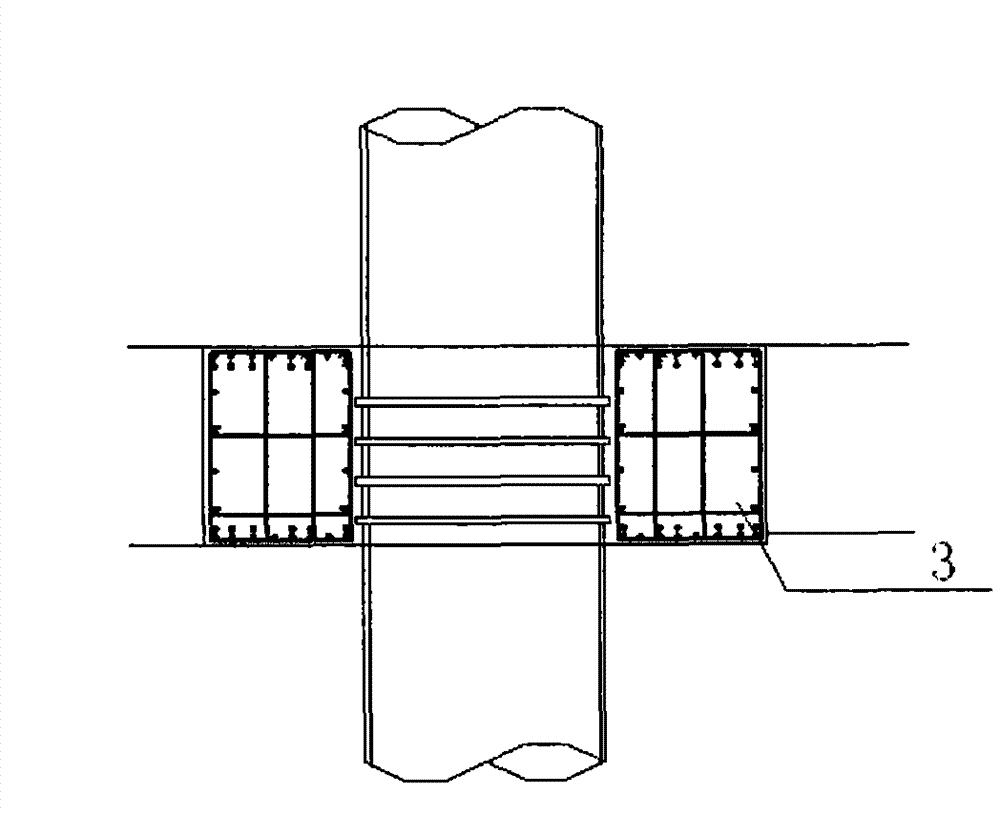

[0070] A steel pipe column ring beam steel bar binding construction method, including the ring beam steel bar binding in general, the ring beam steel bar binding with connectors, and the ring beam steel bar binding at the part connected with the outer wall, characterized in that:

[0071] In the general case described, i.e. without connectors and without connection to the external wall, the binding of the ring beam reinforcement at the intersection of the steel pipe column with the floor slab normally involves the following steps:

[0072](1) Put all the ring-shaped longitudinal steel bars of the ring beam into the steel pipe concrete column, then gather all the longitudinal steel bars together and tie them with iron wires; the ring beam is longitudinally close to the 5 rows of horizontal steel bars on the inner side of the steel pipe column, and processed into two semicircles For steel bars, one of the joints is welded on one side, and the other joint is connected by a straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com