Prefabricated ultra-high performance concrete honeycomb arch bridge structure and construction method thereof

An ultra-high performance, bridge structure technology, applied in the field of bridge engineering, can solve the problems such as the inability to effectively guarantee the economy, the quality of the arch bridge is difficult to guarantee, and the rise-span ratio cannot be too small, so as to reduce the demand for formwork, increase the aesthetics, The effect of reducing the difficulty of rebar binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

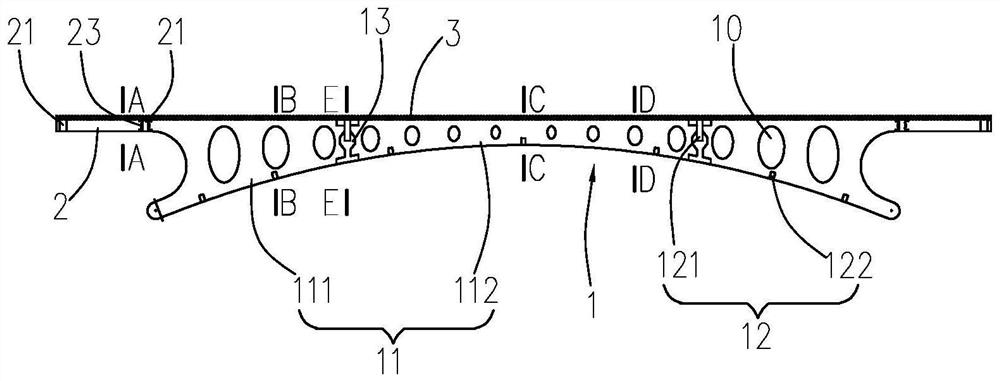

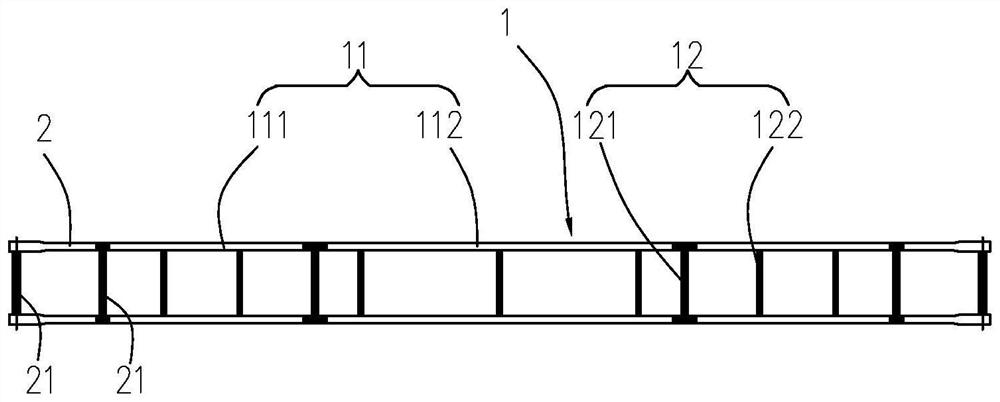

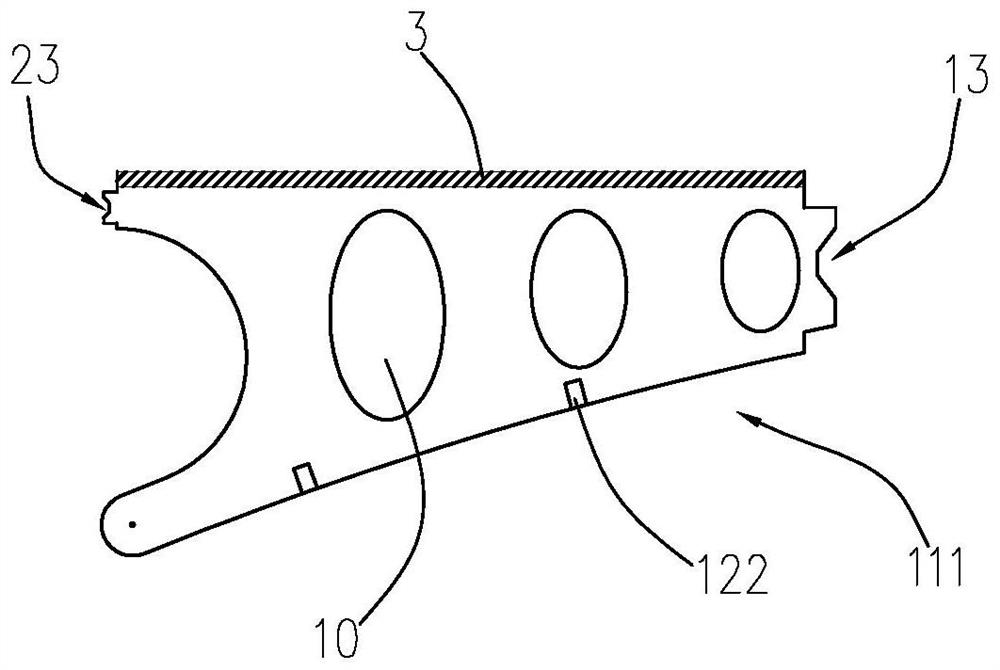

[0045] Please refer to Figure 1 to Figure 13 , the prefabricated ultra-high performance concrete honeycomb arch bridge structure of the present invention includes an arch unit 1, a rigid frame unit 2, and a bridge deck unit 3, wherein the rigid frame unit 2 is connected to the arch unit 1, and the bridge deck unit 3 is laid on the arch unit 1 and 2 surfaces of the rigid frame unit.

[0046] The arch unit 1 is horizontally prefabricated in segments using ultra-high performance concrete materials. During the prefabrication process, by setting a column structure on the formwork, the formed arch unit has several holes 10. The holes 10 can not only reduce the The weight of the arch unit can also increase the beauty of the bridge. Specifically, the shape of the hole 10 may be circular, oval or other shapes.

[0047] In this embodiment, there are at least two arch units along the transverse bridge of the bridge, which can widen the bridge deck. Correspondingly, the positions, sha...

Embodiment 2

[0067] The structure is basically the same as in Example 1, the difference is that there are three arch units in the transverse bridge direction, and the thickness of each arch unit is 30cm.

[0068] Compared with the prior art, the prefabricated ultra-high performance concrete honeycomb arch bridge structure and construction method thereof provided by the present invention have the beneficial effects of:

[0069] 1. The prefabricated ultra-high-performance concrete honeycomb arch bridge structure provided by the present invention adopts the ultra-high-performance concrete prefabricated arch piece as the main force-bearing member, which can fully exert its ultra-high compressive strength performance, thereby reducing material consumption and structural size, Maximize the slenderness of the arch bridge; and open holes in the middle of the arch unit where the force is less, on the one hand reduce the weight of the arch unit, lower the requirements for the substructure, and reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com