Water-adding viscosity-reducing device

A technology for reducing viscosity and water pipelines, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc. It can solve the problems of oilfields not being able to be exploited normally, increasing costs, etc., and achieve the effects of convenient management, fuel saving, and simple production shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

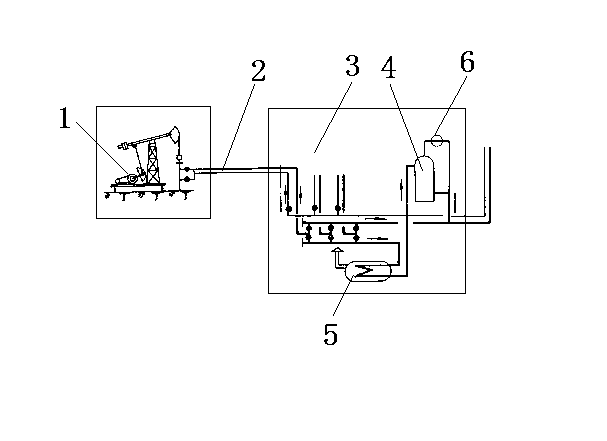

[0009] combined with figure 1 , to further describe the present invention:

[0010] This utility model is mainly composed of a well site 1, an oil delivery pipeline 2, a metering station 3, and a water mixing pipeline 7. The well site 1 is connected to the oil delivery pipeline 2 and the water mixing pipeline 7 respectively, and the oil delivery pipeline 2 is connected to the metering station 3 , the metering station 3 includes a metering separator 4 and a heating furnace 5, the heating furnace 5 is fixed on the oil outlet pipeline 2, and the oil outlet pipeline 2 is connected to the metering separator 4 through the heating furnace 5, and the metering separation The device 4 is provided with a control valve 6 .

[0011] When the oil well is exploited, active water is mixed into the well through this device, which solves the problem of high-viscosity crude oil exploitation. It is easy to put into production, easy to stop production, convenient to manage, and safe to produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com