A Mine Austrian Ash Top Reconstruction and Construction Method Based on Kilometer Directional Drilling Technology

A construction method and mine technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of large number of openings, large-scale bedding area treatment of difficult high-pressure Austrian ash aquifers, and low hole utilization rate. Achieve the effect of increasing mechanical strength and solving deep mining problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

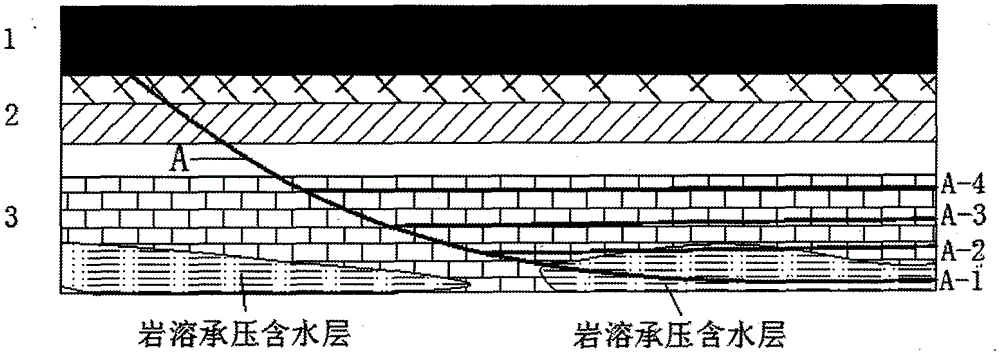

[0024] A certain coal mine is a deep well and large water mine with a buried depth of more than 700m and a static water pressure of 6Mpa. The floor rock of its mining area ( figure 1 ) Are: lower coal 1, impermeable mudstone layer 2, Ordovician limestone 3. The mining of the lower group of coal faces the problem of insufficient safety thickness of the water blocking floor. At the same time, there are two groups of water conducting faults (water conducting faults 9, 10) developed in the stope area. In order to carry out grouting transformation to Ordovician limestone aquifers and water-conducting structures, under the premise of ensuring coal mine safety production, the technical scheme of the present invention is adopted to advance the transformation of mining area floor, liberating mineral resources. The implementation process is as follows:

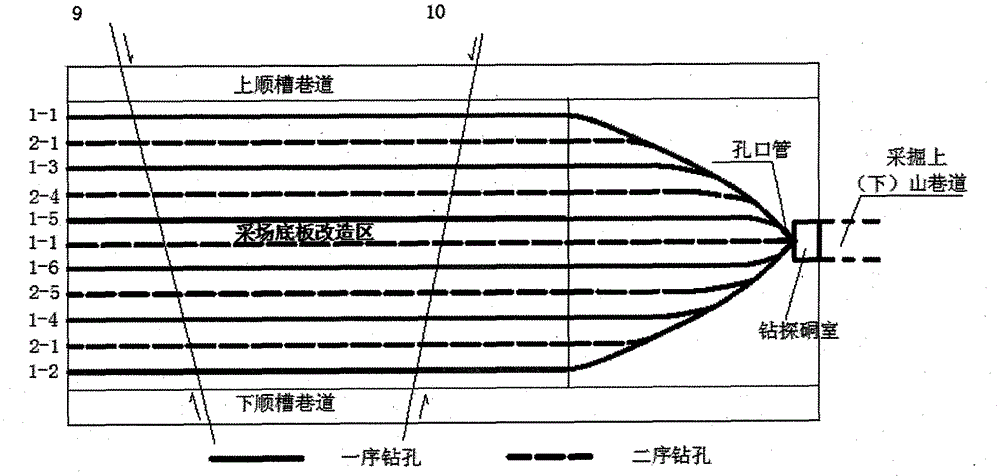

[0025] (1) such as figure 2 According to the engineering technical requirements, a drilling chamber is arranged in the downhill roadwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com