A Downhole Electro-hydraulic Control Fracturing Sleeve

A fracturing sliding sleeve, electro-hydraulic control technology, applied in wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve problems such as inconvenient switching operations, and achieve simple and convenient operation and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

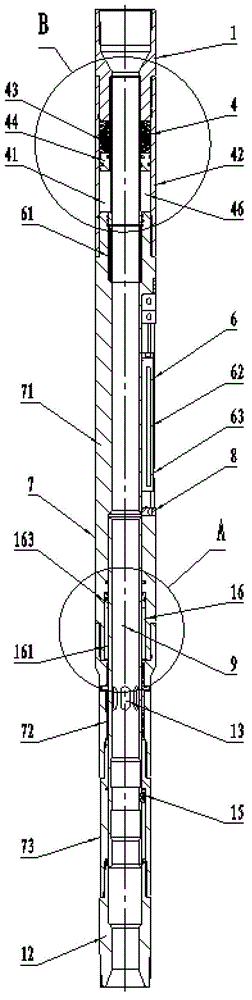

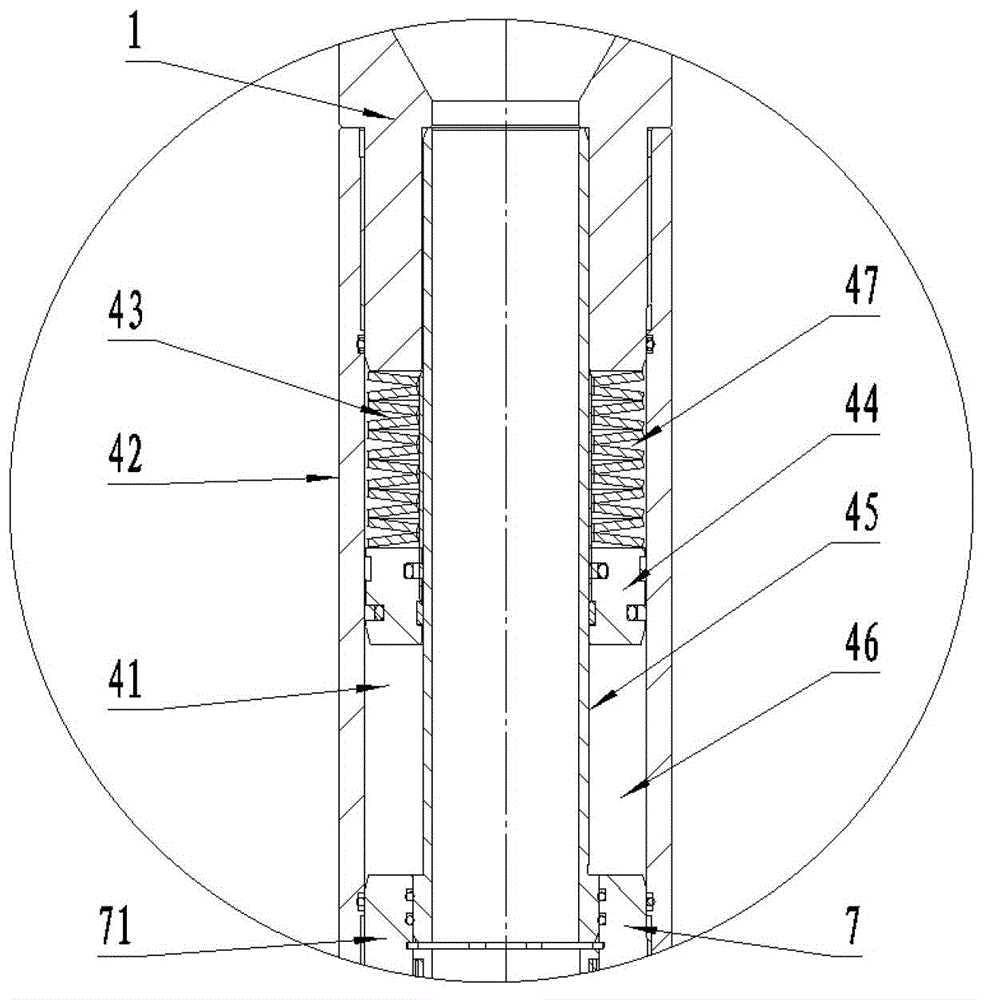

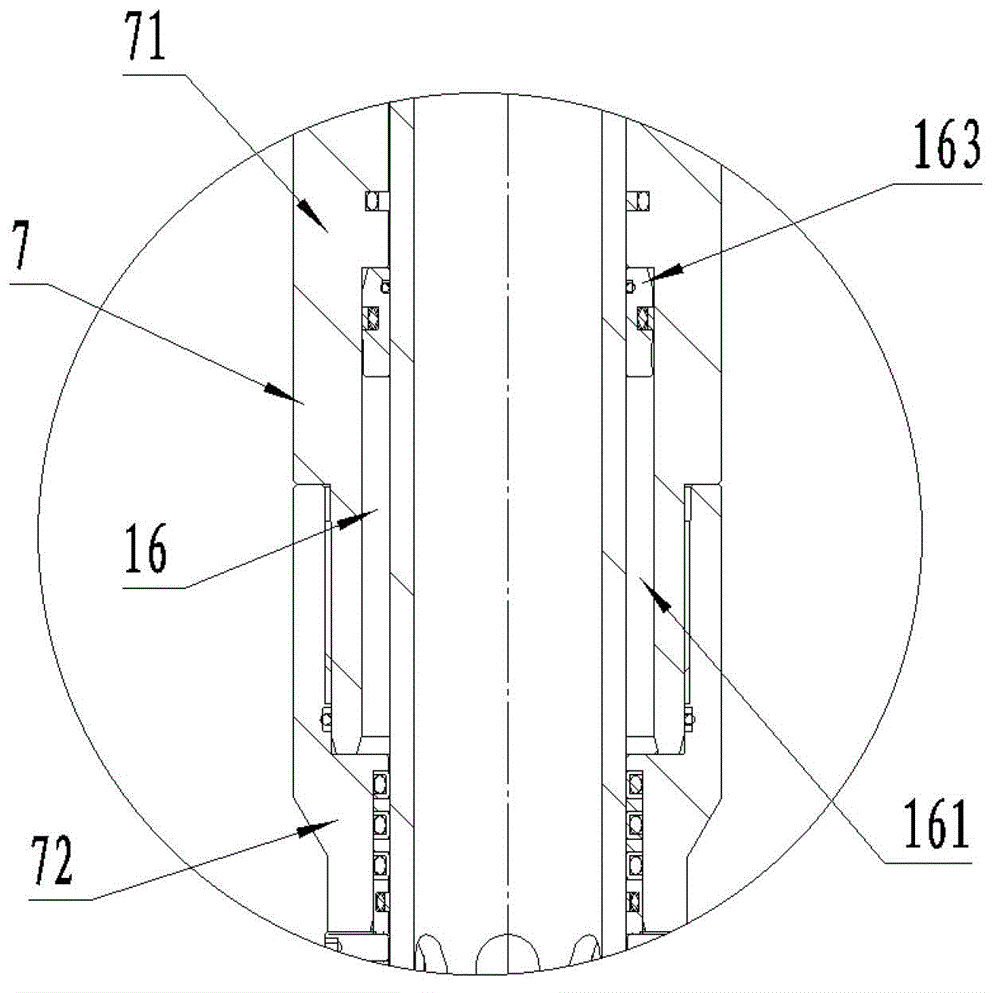

[0023] The downhole electro-hydraulic controlled fracturing sliding sleeve of the present invention will be described in detail below with reference to the accompanying drawings. A downhole electro-hydraulic controlled fracturing sliding sleeve includes an outer sleeve 7 and an inner sleeve 9 arranged in the outer sleeve 7. The two ends of the inner sleeve 9 are connected to the outer sleeve 7 in a sealed manner, and the inner sleeve 9 can run along Along with the axial sliding of the outer sleeve 7, a closed annular cavity 16 is provided between the outer sleeve 7 and the inner sleeve 9. In the annular cavity 16, a closed annular cavity 16 is sequentially connected along the axial direction of the outer sleeve 7. The first oil storage cavity 161, the annular sliding sleeve piston 163 fixedly connected to the inner sleeve 9, and the closed second oil storage cavity 162. The downhole electro-hydraulic controlled fracturing sliding sleeve also includes a hydraulic oil supply Devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com