Method for controlling temperature of heat-transfer medium (HTM) furnace evaporator

A technology of evaporator temperature and control method, which is applied to fluid heaters, lighting and heating equipment, etc. It can solve the problems of untimely control, large deviation, and inability to ensure that the temperature is in the required range, and achieve the effect of improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and specific operation processes, but the protection scope of the present invention is not limited to the following described embodiment.

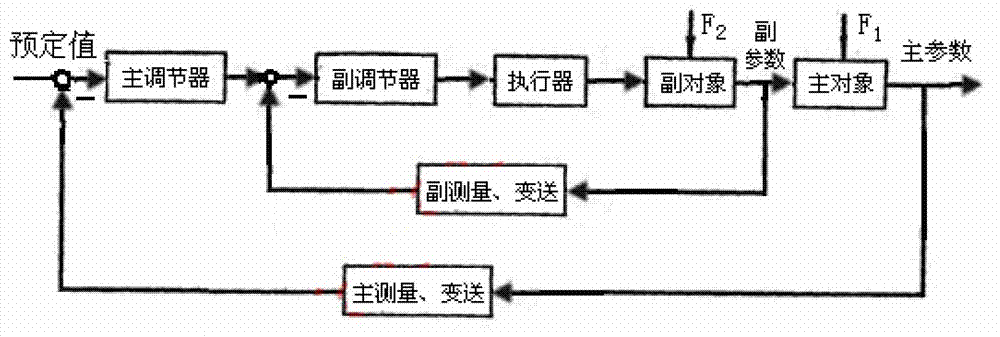

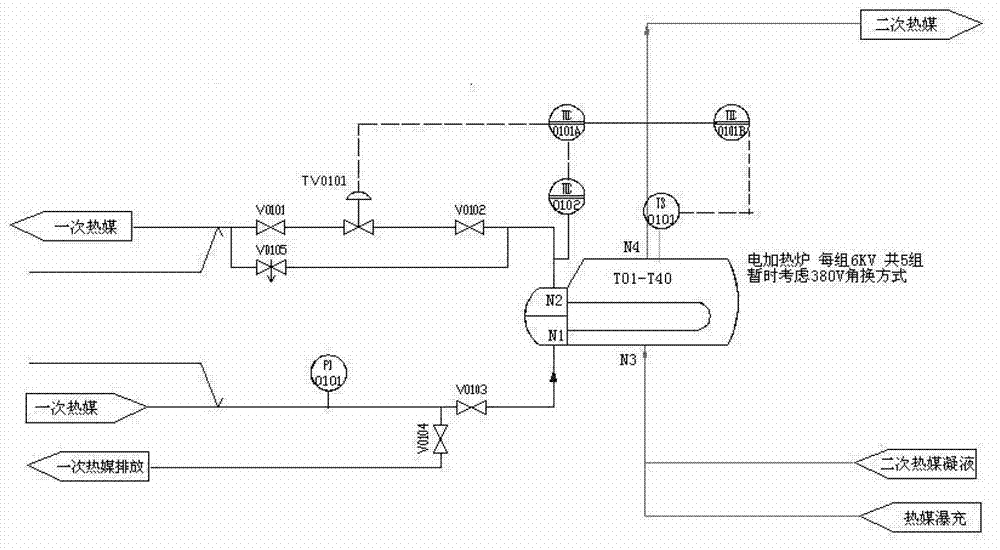

[0020] figure 1 It is the PID cascade control flow chart of the present invention, such as figure 1 In the shown heating medium furnace evaporator temperature control method, the primary heating medium inlet is provided with a second temperature sensor, and the second temperature sensor is connected to the second analog input module as a secondary object, and a secondary regulator is correspondingly set; The secondary heat medium outlet is provided with a first temperature sensor, and the first temperature sensor is connected to the first analog input module as the main objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com