Temperature control system for evaporator of heat medium heater

A technology of evaporator temperature and control system, which is used in fluid heaters, lighting and heating equipment, etc., can solve problems such as untimely control, inability to ensure that the temperature is in the required range, and large deviation, and achieve the effect of improving the response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

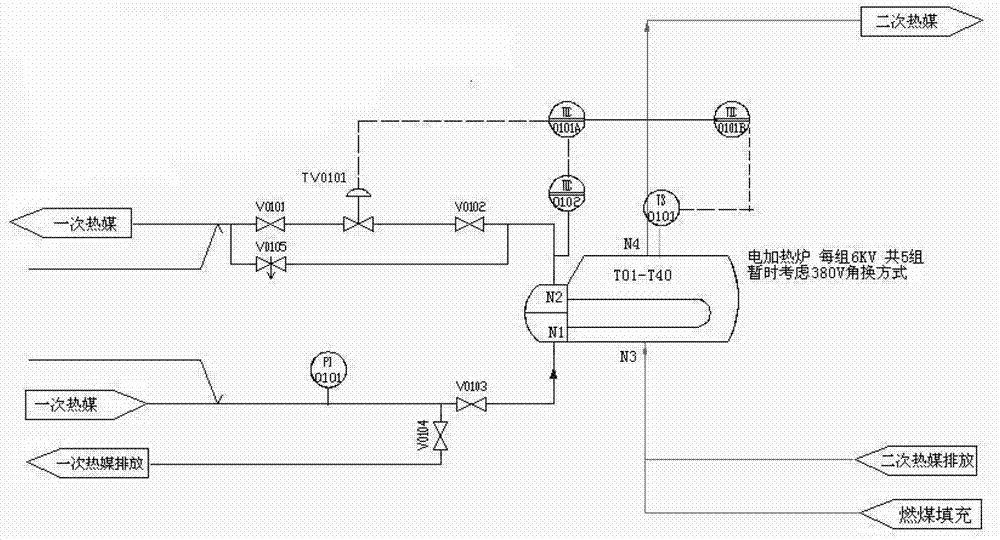

[0013] Example 1: PID process of heat medium furnace evaporator temperature control system

[0014] figure 1 Shown is the PID flow chart of the heat medium furnace evaporator temperature control system of the present invention, the system includes a programmable controller PLC, an analog input module, an analog output module, a PID module, a primary heat medium inlet regulating valve, and a primary heat medium outlet , the secondary heating medium inlet, the secondary heating medium outlet and the electric heating furnace, wherein, the programmable controller PLC adopting the PID algorithm is respectively connected with the analog input module, the analog output module and the electric heating furnace, and the electric heating The furnace is respectively connected with the primary heat medium inlet regulating valve, the primary heat medium outlet, the secondary heat medium inlet, and the secondary heat medium outlet. The temperature of the secondary heat medium outlet is inp...

Embodiment 2

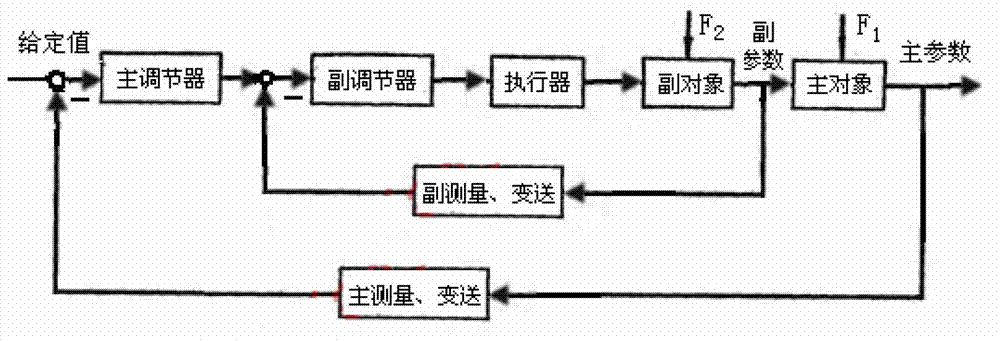

[0015] Embodiment 2: PID cascade control structure of heat medium furnace evaporator temperature control system

[0016] figure 2 It is a PID cascade control structure diagram of the heat medium furnace evaporator temperature control system of the present invention. Such as figure 2 As shown, among them, 1. Primary heat medium temperature is the secondary object; 2. The secondary heat medium temperature is the main object; 3. The primary heat medium temperature regulator is a secondary regulator; 4. The secondary heat medium temperature regulator is the main regulator.

[0017] The main regulator, that is, the secondary heat medium temperature regulator plays the role of fine adjustment and implements fixed value control; the secondary regulator, that is, the primary heat medium temperature regulator plays the role of coarse adjustment and implements follow-up control. The main loop is composed of main regulator, sub-regulator, actuator, sub-object (primary heat medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com