Mop bucket and mop tray matched with same

A technology for mop buckets and mop discs, which is applied in the direction of cleaning carpets, floors, and cleaning equipment. It can solve the problems of inconvenient operation, complicated deceleration device, and difficult alignment, and achieves easy alignment and positioning, good cleaning effect, and reduced speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

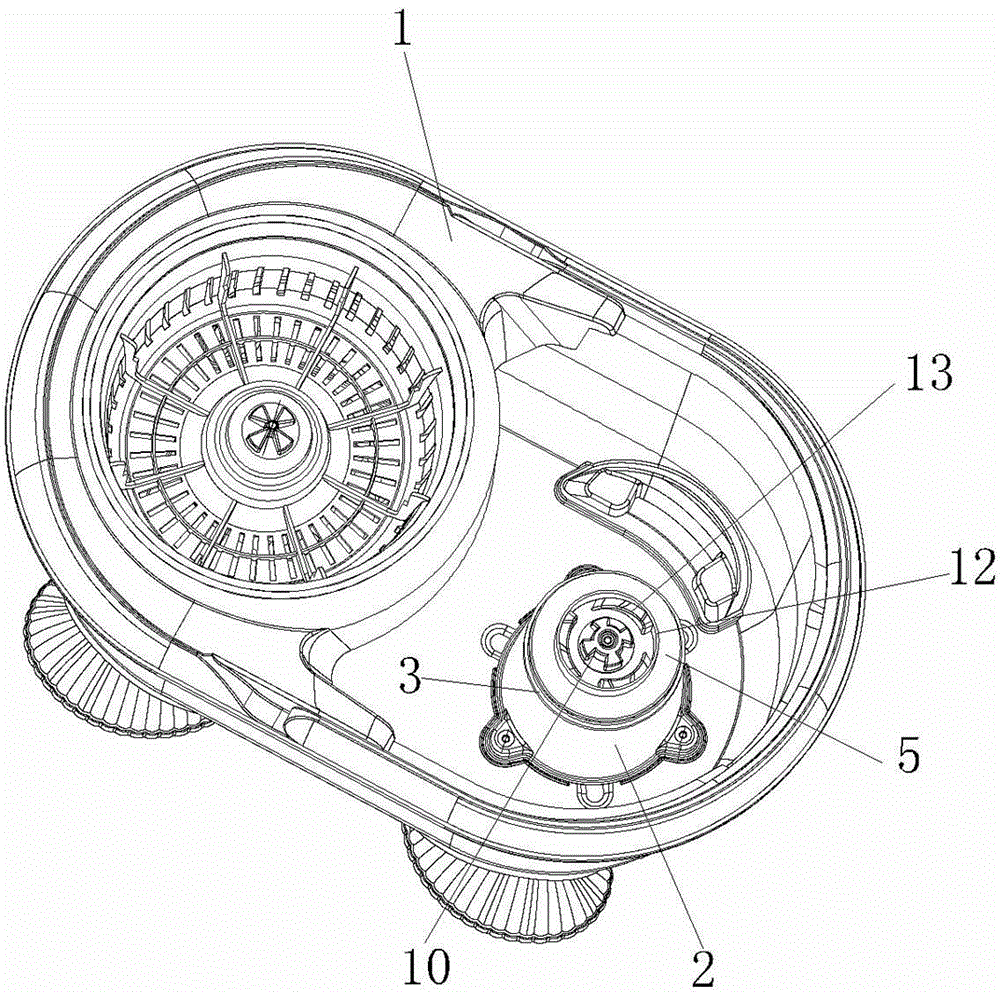

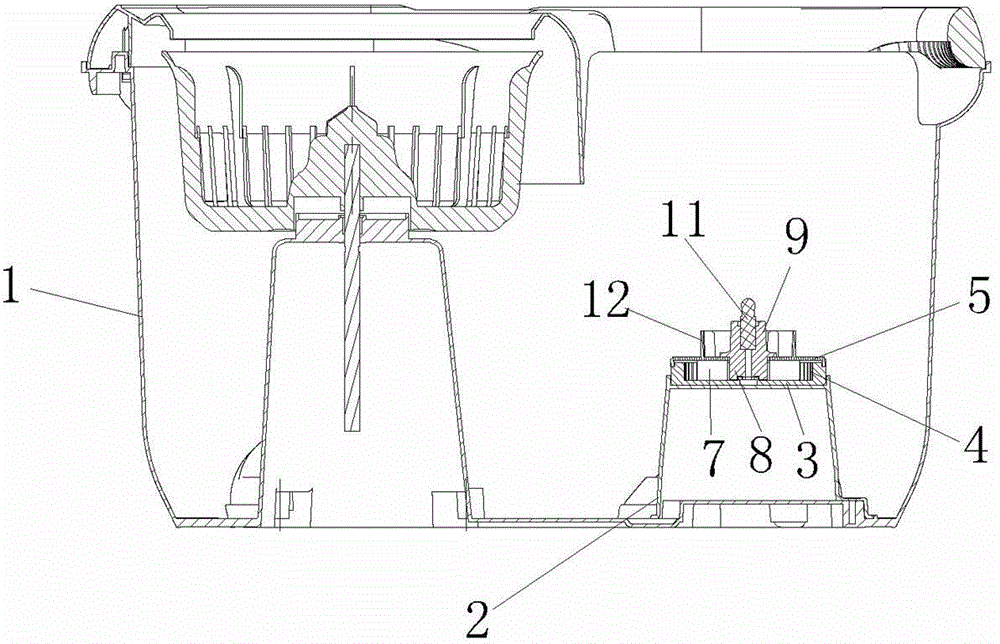

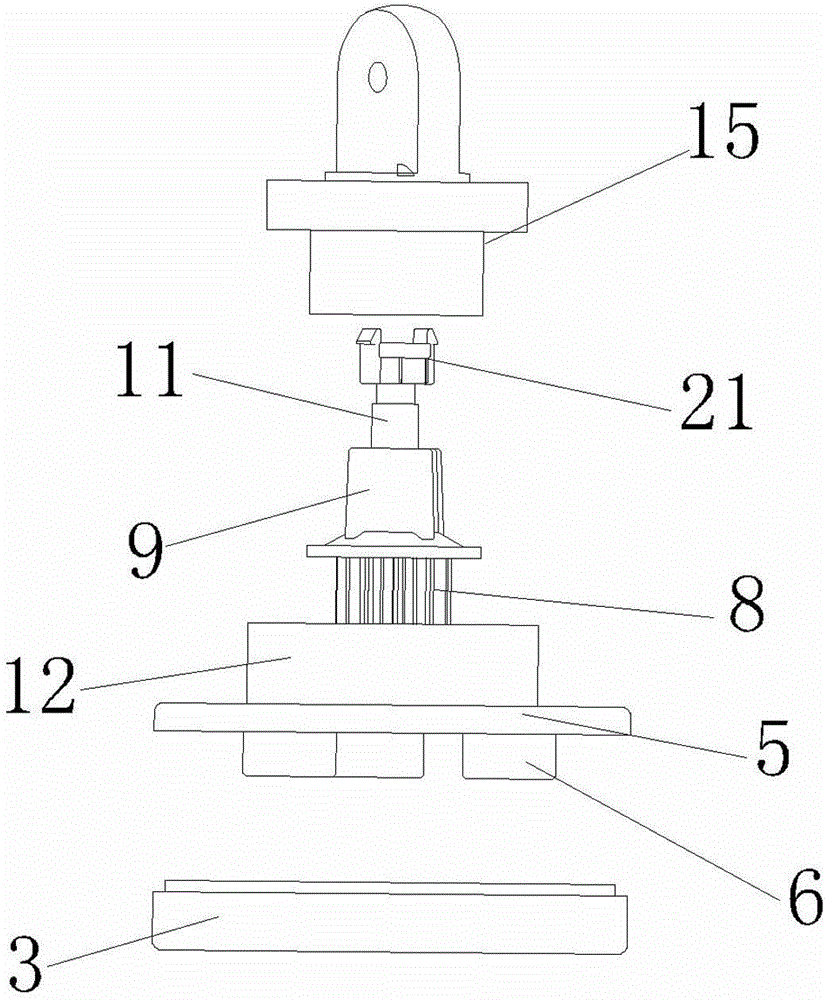

[0049] refer to Figure 1~Figure 5 , Figure 8~Figure 11 , in this embodiment, the axial positioning method of the rotating body 15 is as follows: the center of the disc body 14 is provided with a through opening, the rotating body 15 is provided with a positioning convex ring 26, and the positioning convex ring 26 below The rotating body penetrates into the through opening, and the positioning protrusion ring 26 leans against the upper end surface of the disc body 14 . The positioning convex ring 26 is also covered with a compression cover 27, and the compression cover 27 is also covered with a compression ring 28. The compression ring 28 is provided with a buckle. A bayonet is provided, and the buckle is snapped into the bayonet so as to press the pressing cover 27 on the positioning convex ring 26 . In this embodiment, the back of the disc body 14 is further provided with a shielding ring 29 that shields the bayonet socket.

[0050] The rest of the structure and implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com