Patents

Literature

34results about How to "Reduce the degree of offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

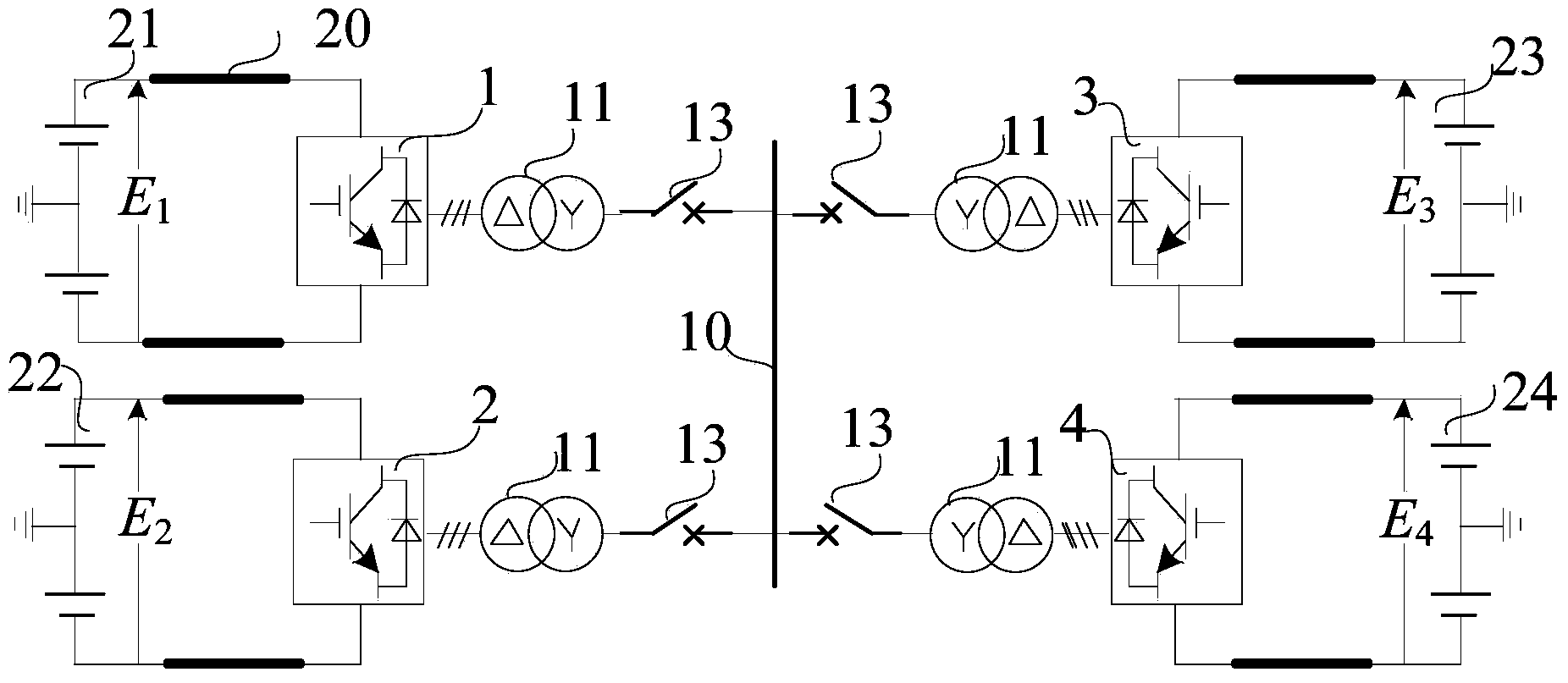

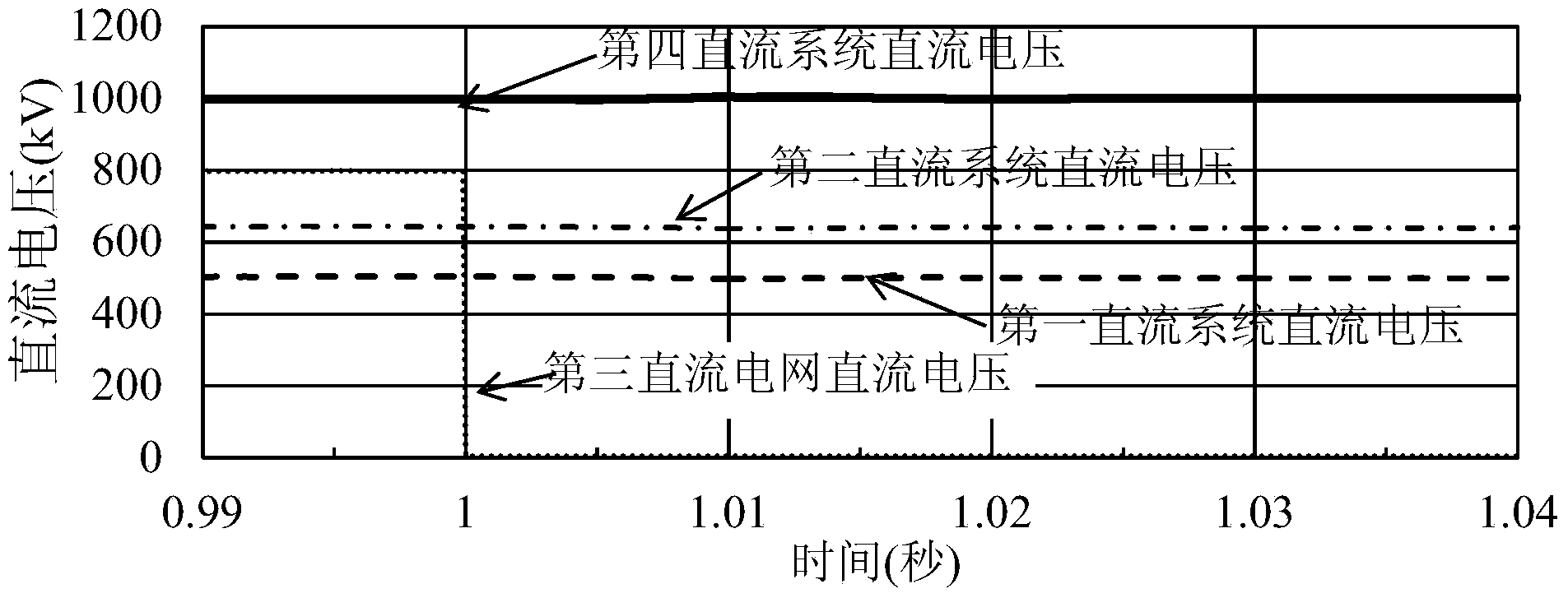

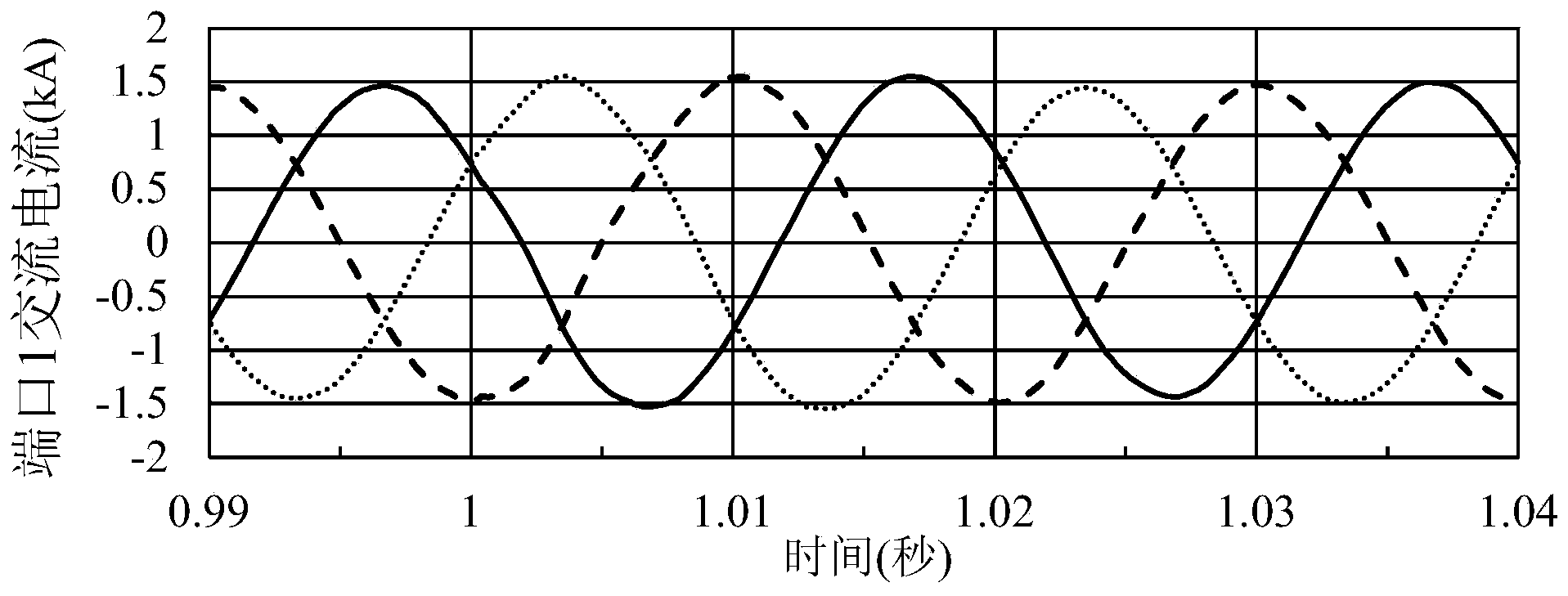

Multiport back-to-back DC-DC converter

InactiveCN104022499AReduce lossLow running costDc-dc conversionDc source parallel operationDc dc converterTransformer

The invention provides a multiport back-to-back DC-DC converter which comprises a DC system, a converter, an AC transformer, an AC circuit breaker and a common AC bus. One side of the converter is connected with the DC system through a DC line, and the other side of the converter is connected with the common AC bus through the AC transformer and the AC circuit breaker. According to the multiport back-to-back DC-DC converter, multiple DC lines with the same voltage class or different voltage classes are interconnected through two-level DC-AC-DC exchange, DC fault partition isolation is achieved through reasonable control, the cost of the transformer is saved, the safety performance of the DC-DC converter is improved, and the operation safety stability of an entire DC power grid is improved.

Owner:STATE GRID CORP OF CHINA +3

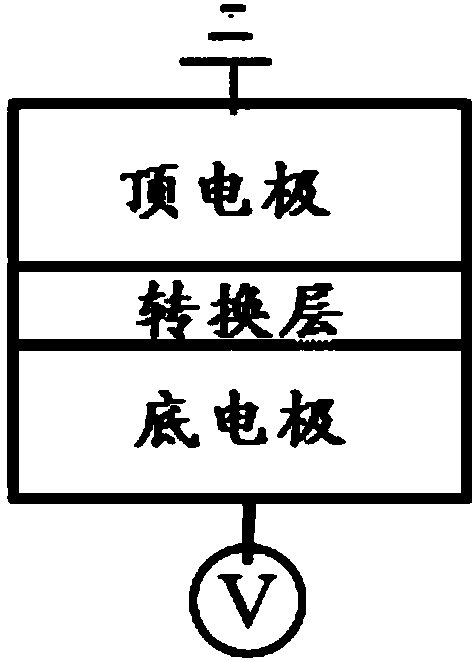

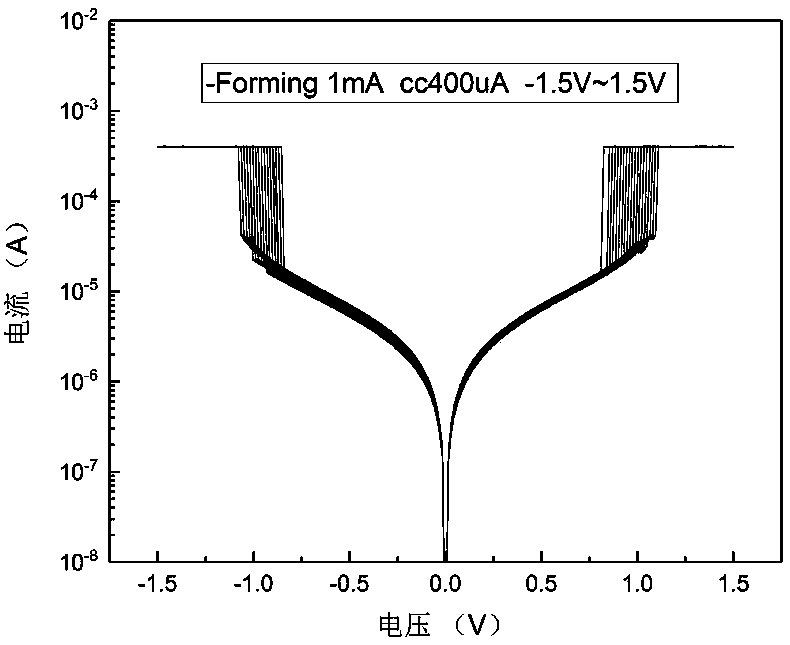

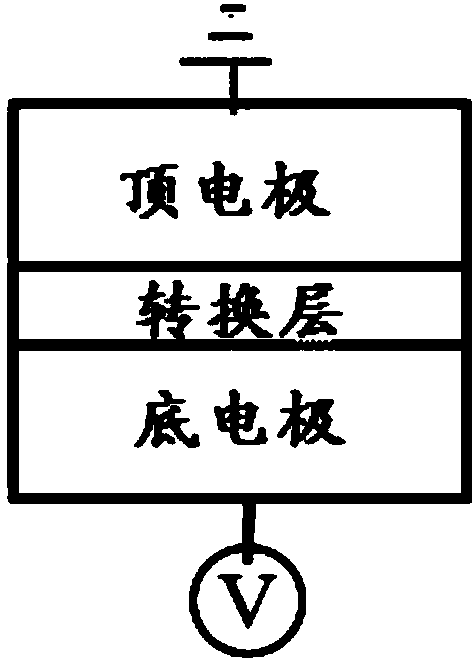

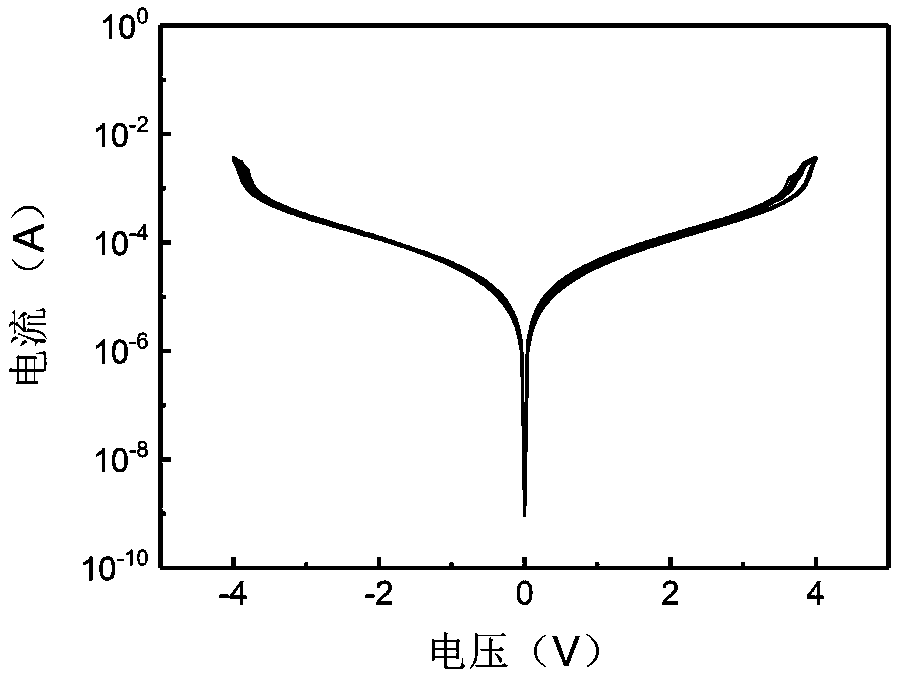

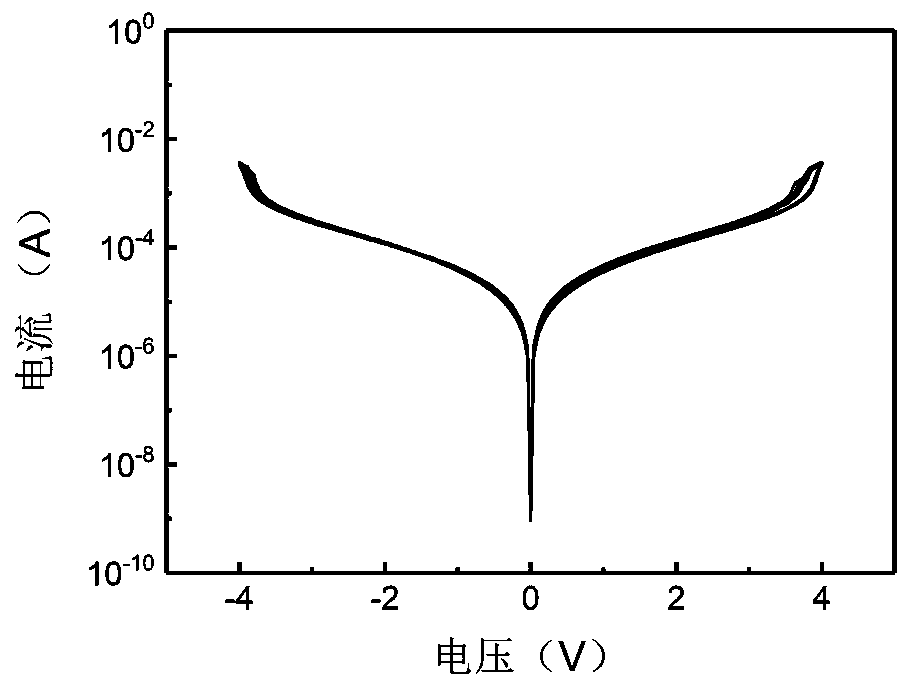

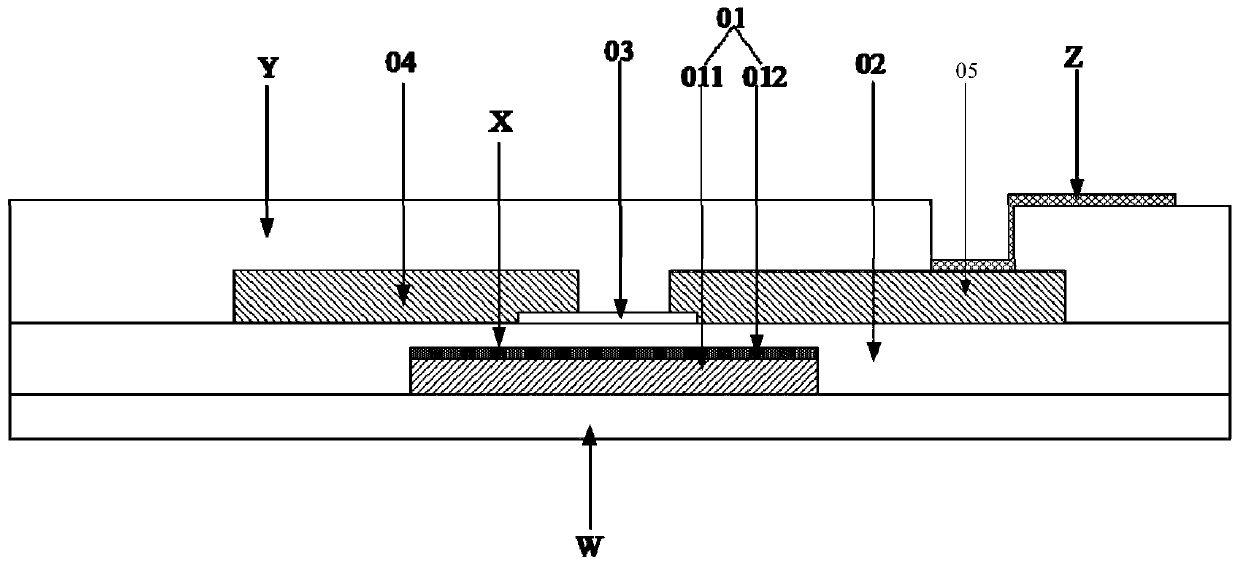

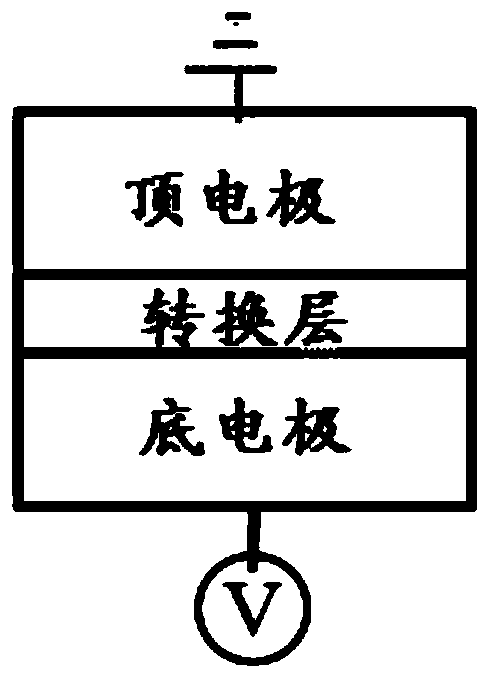

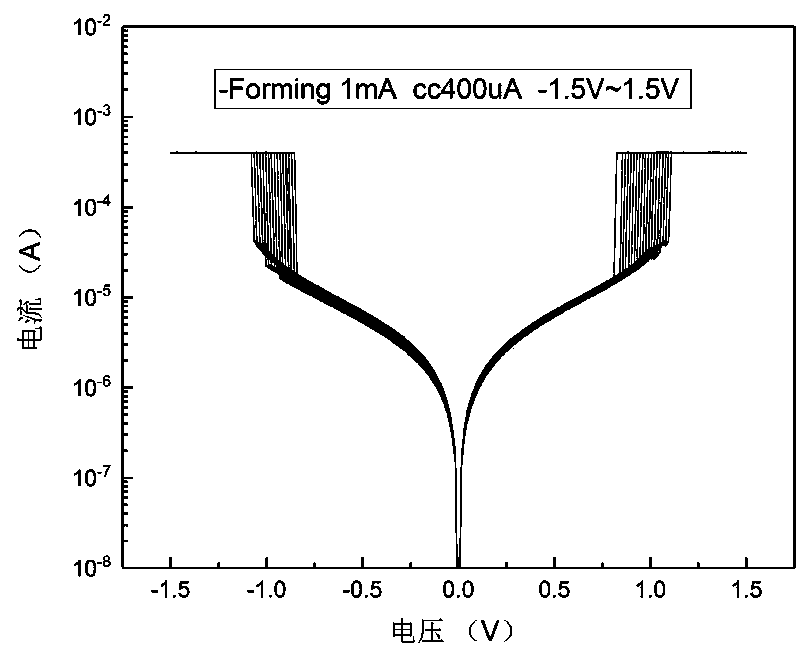

Nb oxide based gating device and preparation method thereof

ActiveCN108539014AReduce the degree of offsetImprove electrical stabilityElectrical apparatusElectrical stabilityOxide

The invention provides an Nb oxide based gating device. The device comprises a bottom electrode, a conversion layer and a top electrode from bottom to top sequentially, wherein the bottom electrode isTiN or conductive glass; the conversion layer is Nb oxide; the top electrode is Pt. Nb oxide as the conversion layer, TiN or the conductive glass as the bottom electrode and Pt as the top electrode constitute the Nb oxide based gating device with excellent electrical stability. Experimental results prove that the deviation degree of an obtained curve is small when the gating device is tested circularly for 100 cycles, which proves that the gating device has excellent electrical stability.

Owner:HUBEI UNIV

Group target tracking method based on image morphological processing

ActiveCN109814074AReduce the degree of offsetHigh precisionRadio wave reradiation/reflectionPattern recognitionRadar

The invention discloses a group target tracking method based on image morphology processing, which comprises the following steps of: processing echo signals received by a radar receiver in a samplingperiod, performing coordinate conversion calculation, establishing an initial image matrix, calculating a binary image matrix, sequentially performing image morphology processing and marking processing on the binary image matrix, calculating an equivalent center vector of a group target in the sampling period, calculating a track set of the group target by adopting a logic method, calculating an initial state of the center of the group target, calculating an association matrix, adjusting a filtering tracking track according to the association matrix, and taking a current filtering tracking track state as a filtering state for predicting the center position of the group target in the next sampling period, and finally obtaining a group target tracking result. According to the method, the group target tracking based on image morphology processing is used in the technical field of radar tracking, not only is the calculation precision of the group target center guaranteed, but also the group target is well tracked under the condition that the group target is partially missing, and the method has valuable practicability.

Owner:XIDIAN UNIV

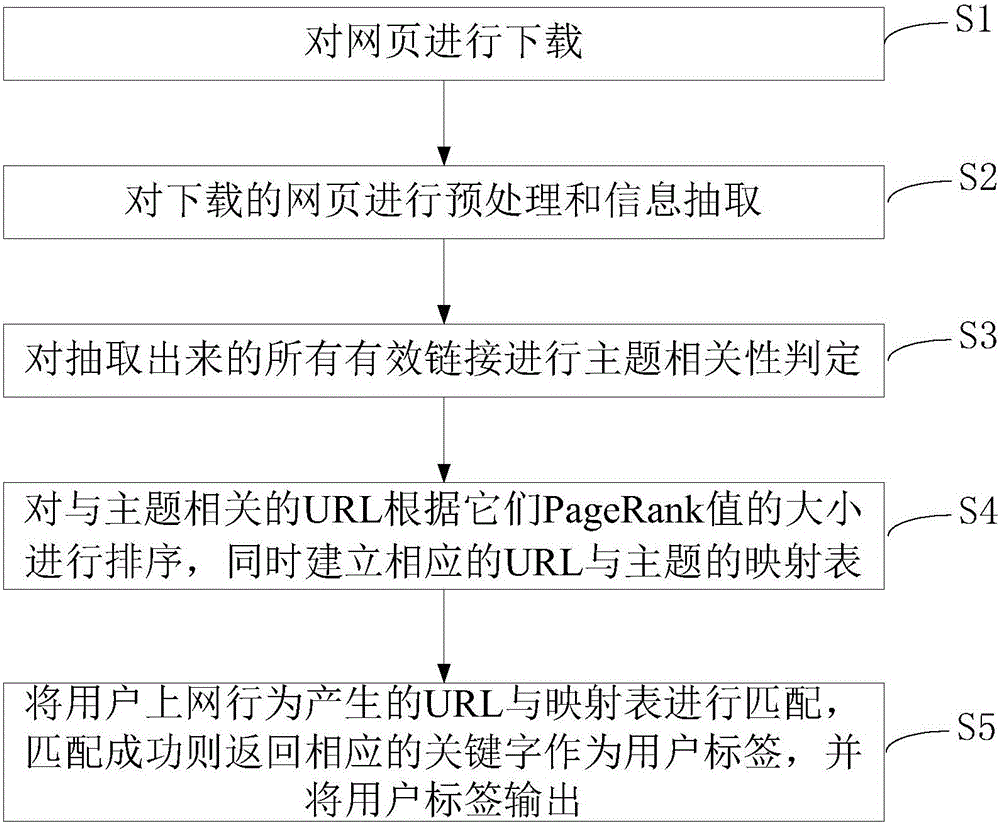

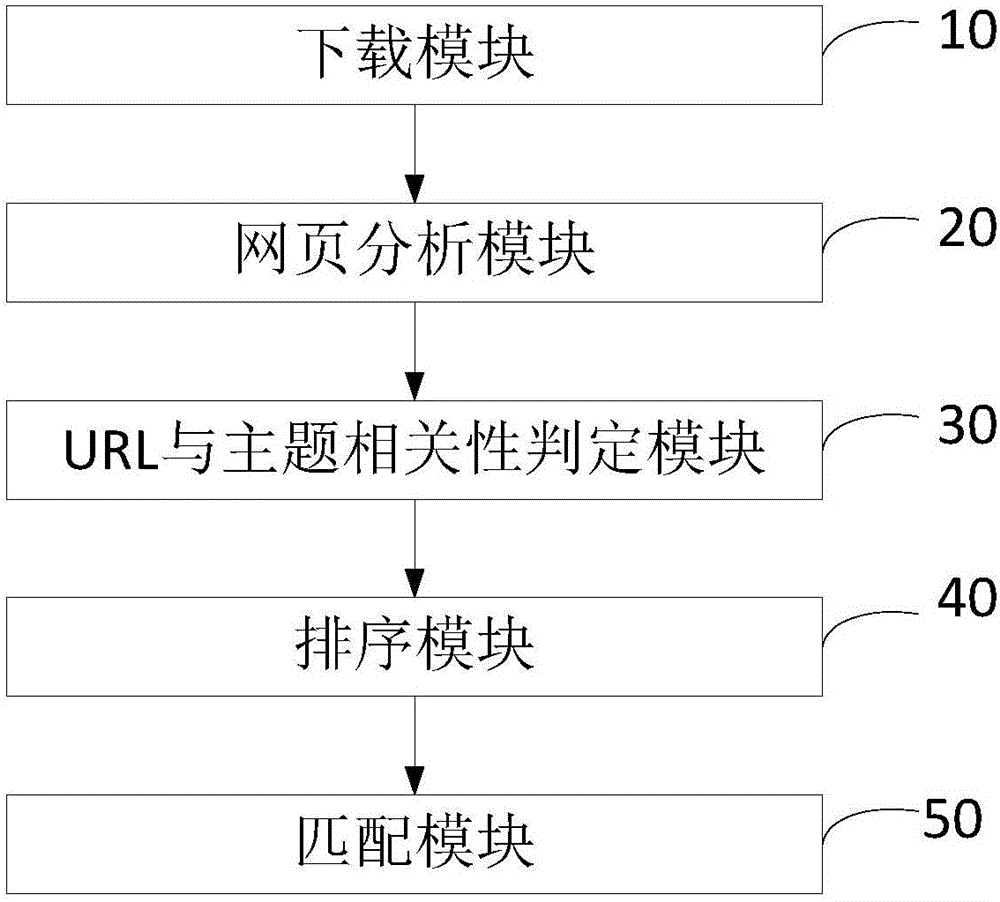

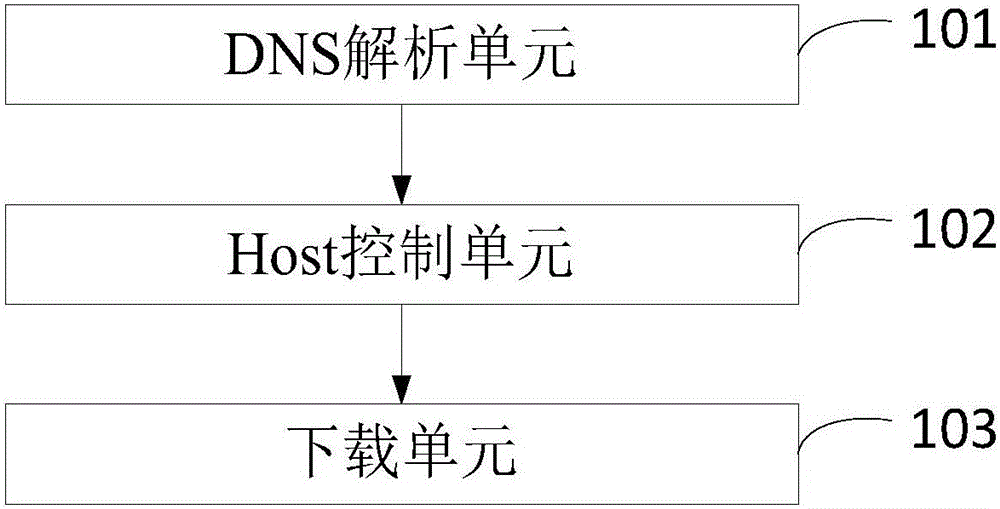

Method and device for analyzing mobile user internet behavior based on URL analysis model

InactiveCN105956004AReduce workloadReduce the degree of offsetWeb data indexingSpecial data processing applicationsBehavioral analyticsThe Internet

The invention provides a method and a device for analyzing mobile user internet behaviors based on a URL analysis model. The device comprises a download module, a webpage analysis module, a URL and topic relevance determination module, an ordering module, and a matching module. Compared with the prior art, the method and a device for analyzing mobile user internet behaviors based on a URL analysis model have beneficial effects in that user internet behavior analysis based on URL analysis is realized, and through using a topical crawler, a mapping table is formed, and the URLs generated by user internet behaviors are used to match with the mapping table, and the URLs are classified in corresponding classifications. Thus, work of the crawler is brought forward before development, and later-phase workload of a system is reduced. In addition, aimed at a defect of topic drift caused by just using a PageRank algorithm by a common topical crawler, before URL ordering, through determining topic relevance, topic offset degree can be reduced on the basis of not substantially increasing complexity of the algorithm.

Owner:GUANGDONG KINGPOINT DATA SCI & TECH CO LTD

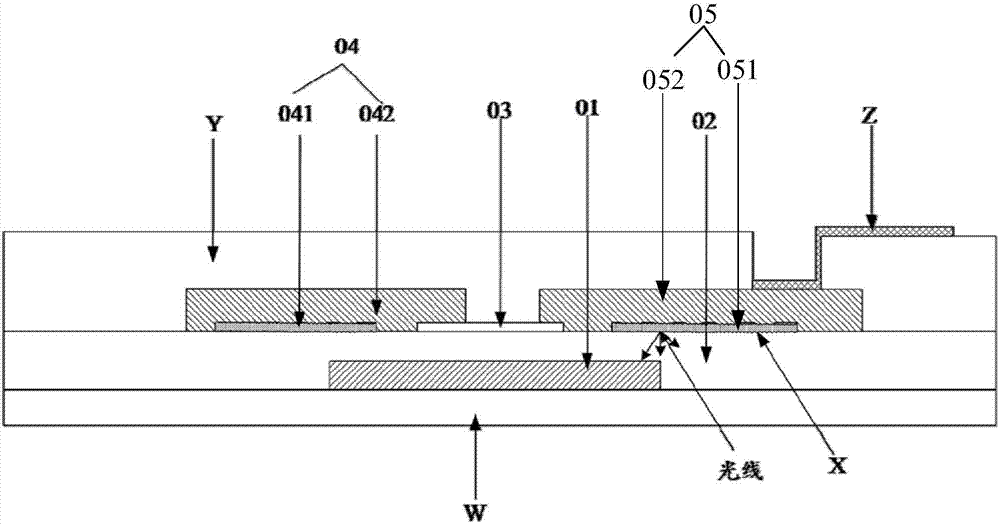

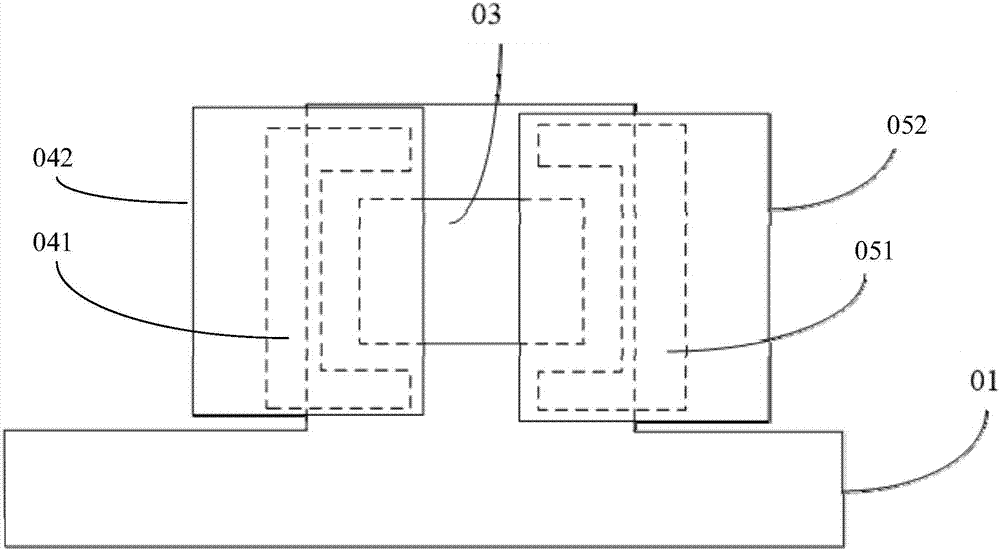

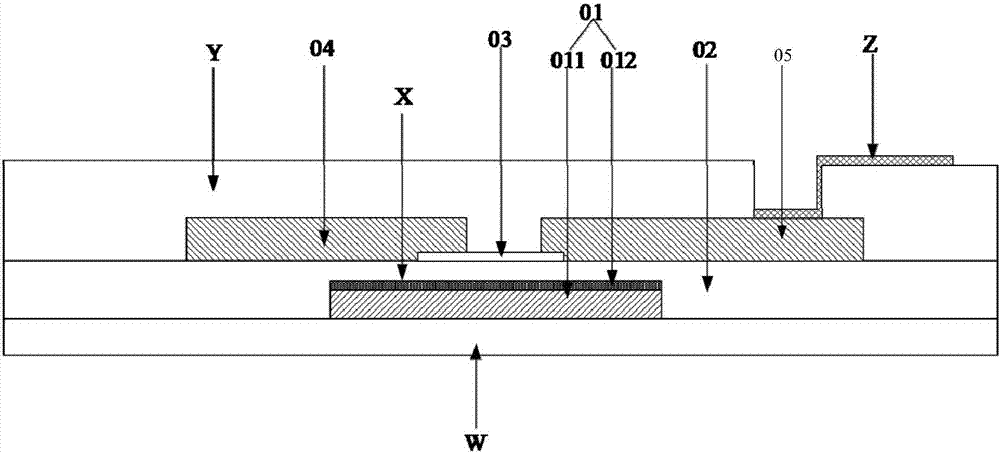

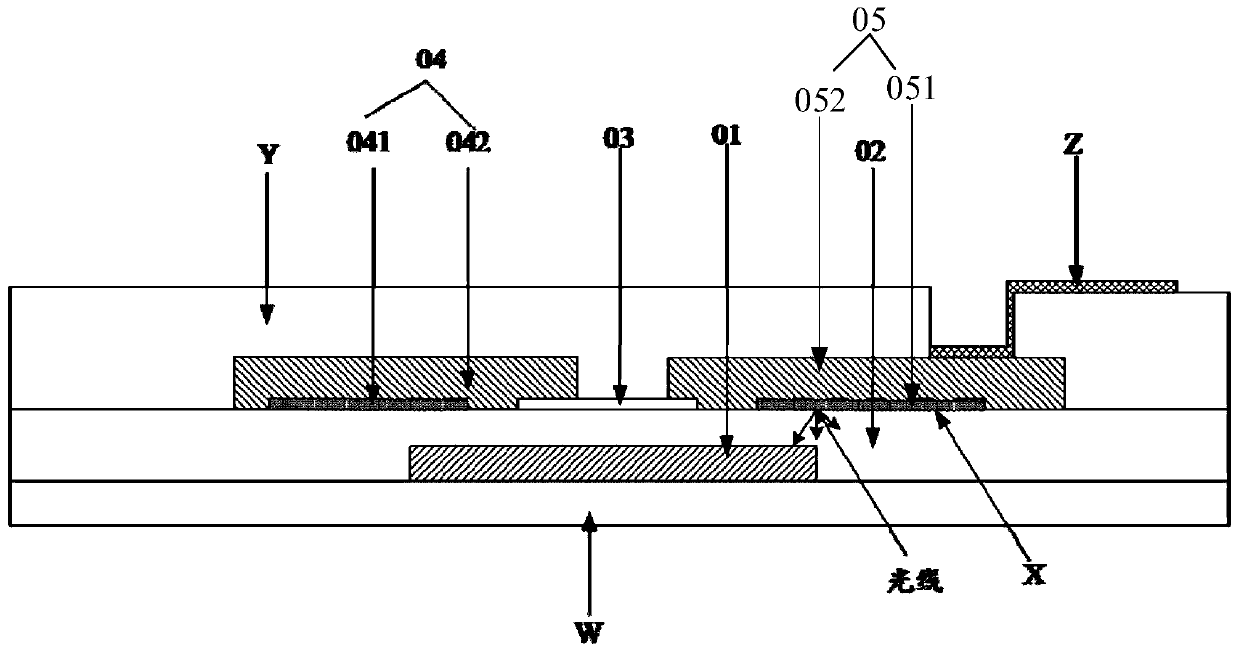

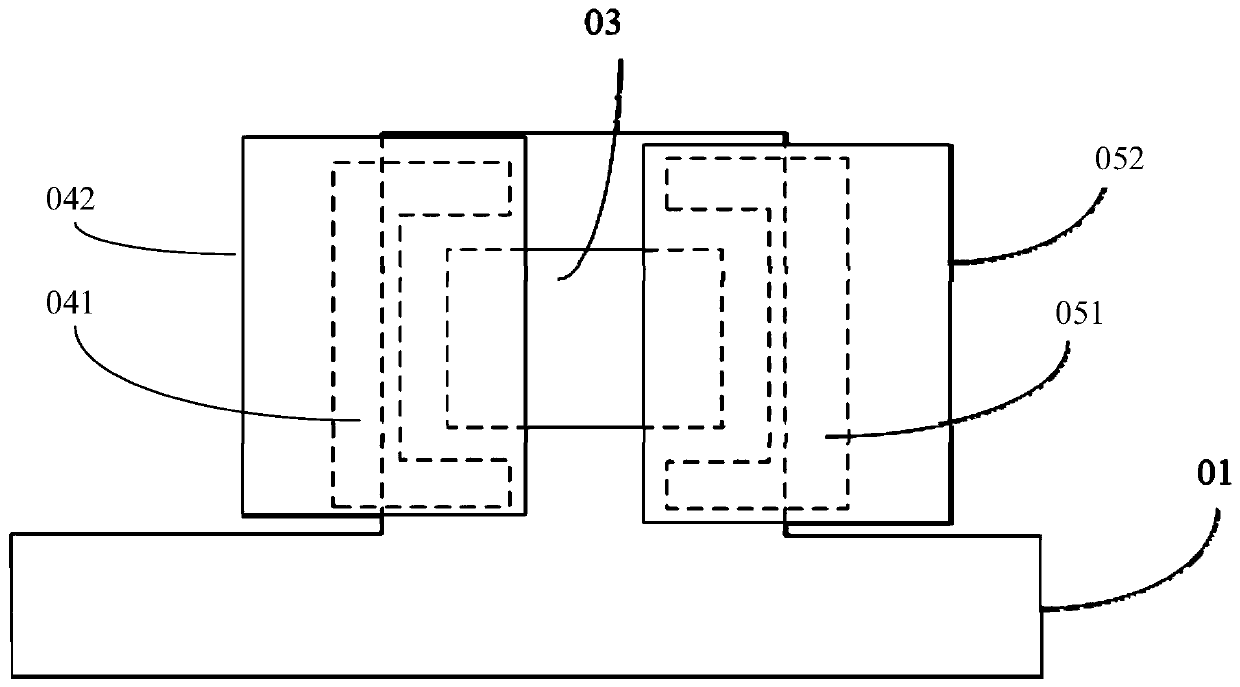

Thin-film transistor and method for manufacturing the same, array substrate, and display device

ActiveCN107123687AReduce the amount of lightReduce the degree of volt-ampere characteristic curve shiftTransistorSolid-state devicesVolt-ampereEngineering

The application, which belongs to the technical field of displaying, discloses a thin-film transistor and a method for manufacturing the same, an array substrate, and a display device. The thin-film transistor comprises a gate pattern, a gate insulating layer, an active layer pattern, a source pattern, and a drain pattern that are laminated successively. At least one of the surface, facing the gate insulating layer, of the source pattern, the surface, facing the gate insulating layer, of the drain pattern, and the surface, facing the gate insulating layer, of the gate pattern is a target surface that is capable of carrying out diffuse reflection on light entering the target surface to prevent entrance of the part of light into the active layer pattern. Therefore, a problem that normal working of a thin-film transistor is affected because of the offset of the volt-ampere-characteristic curve of the active layer pattern can be solved; and thus the influence on normal working of the thin-film transistor by the target light can be weakened. The thin-film transistor is applied to the display device.

Owner:BOE TECH GRP CO LTD +1

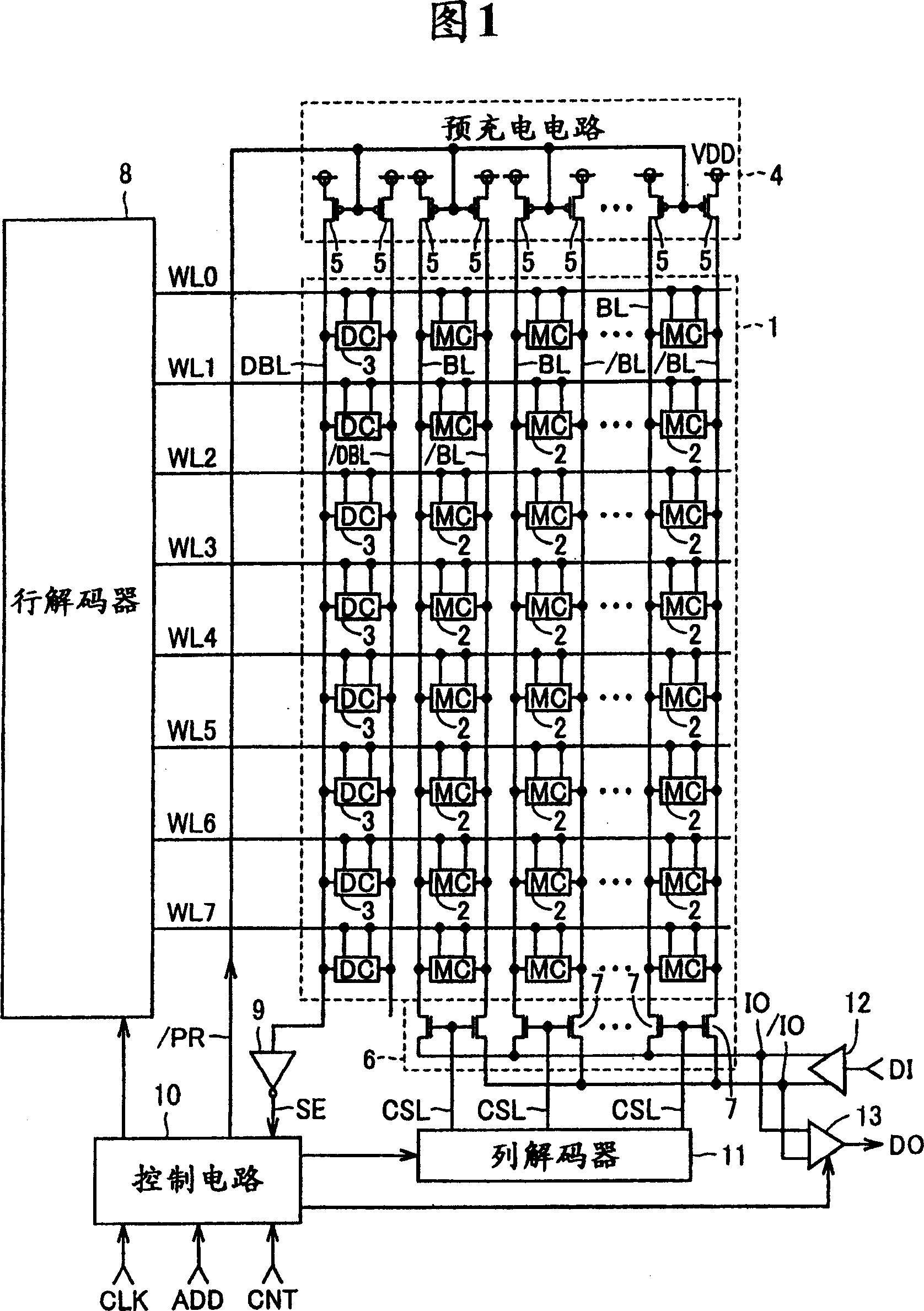

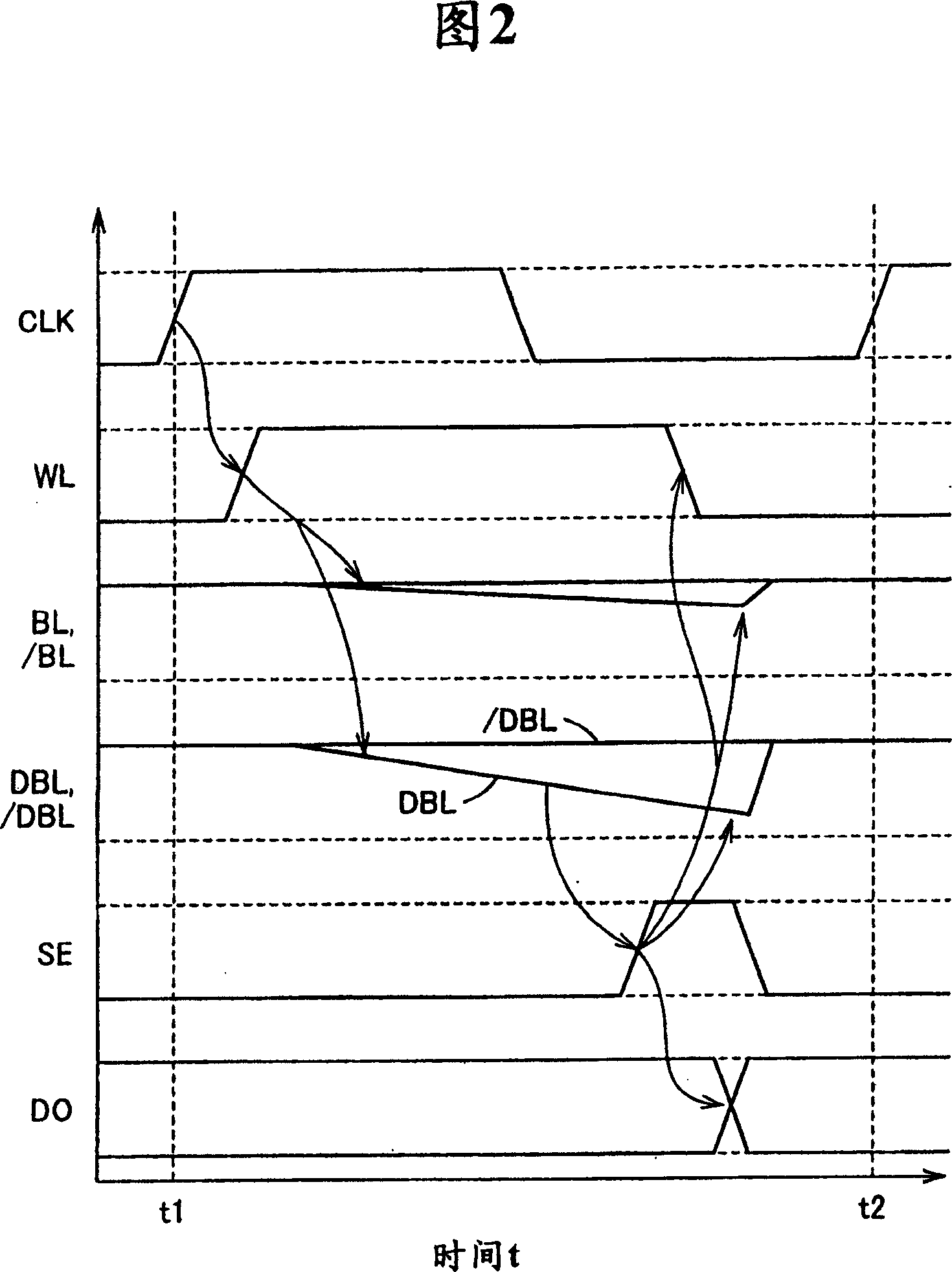

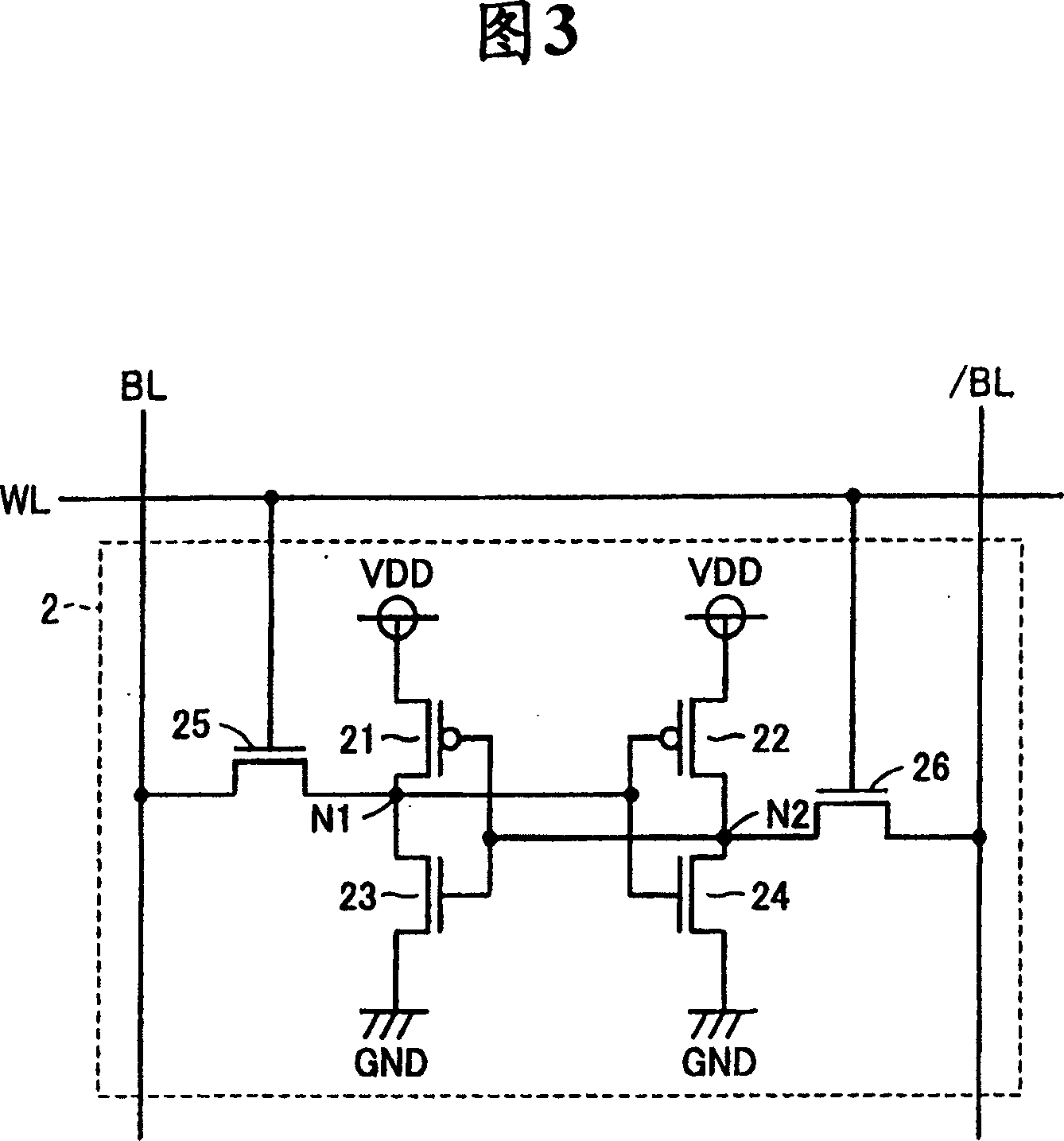

Stable semiconductor storage device with pseudo storage unit

InactiveCN100334652CEasy to changePull down optimizationSolid-state devicesSemiconductor/solid-state device manufacturingN channelStorage cell

The dummy cell of the SRAM corresponds to a normal memory cell of which first and second P-channel MOS transistors for loading are replaced by the first and the second N-channel MOS transistors, of which gate and source are provided with power supply potential and ground potential, respectively. When a word line rises to 'H' level, third and fourth N-channel MOS transistors for accessing are rendered conductive, to pass current from dummy bit line to a line of ground potential via the third N-channel MOS transistor, the first N-channel MOS transistor, and a fifth N-channel MOS transistor for driving. Accordingly, speed of potential decrease of the dummy bit line may be faster than that of bit line. Hence, operational timing can easily be optimized, and operational margin can be increased.

Owner:MITSUBISHI ELECTRIC CORP

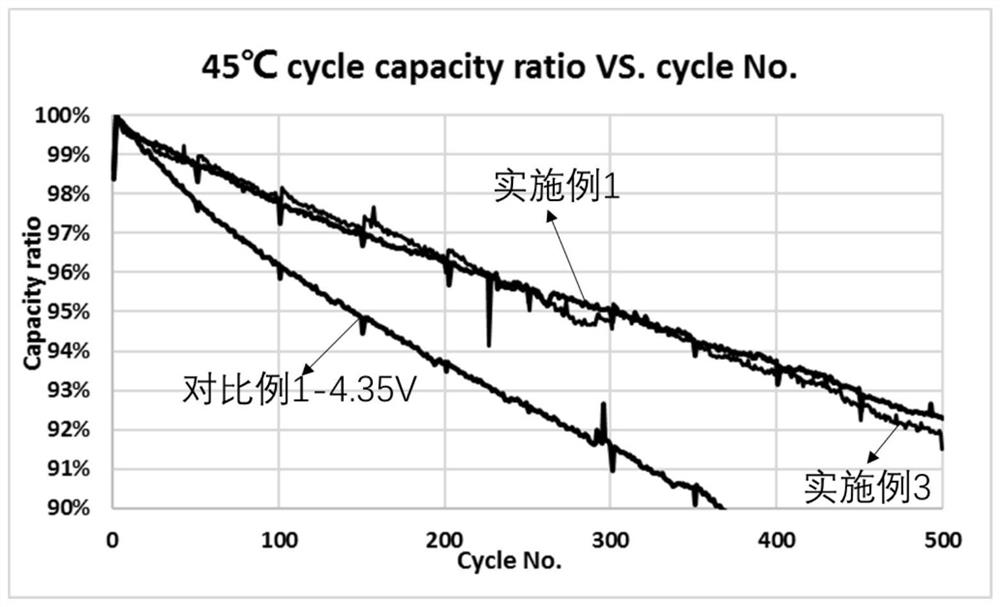

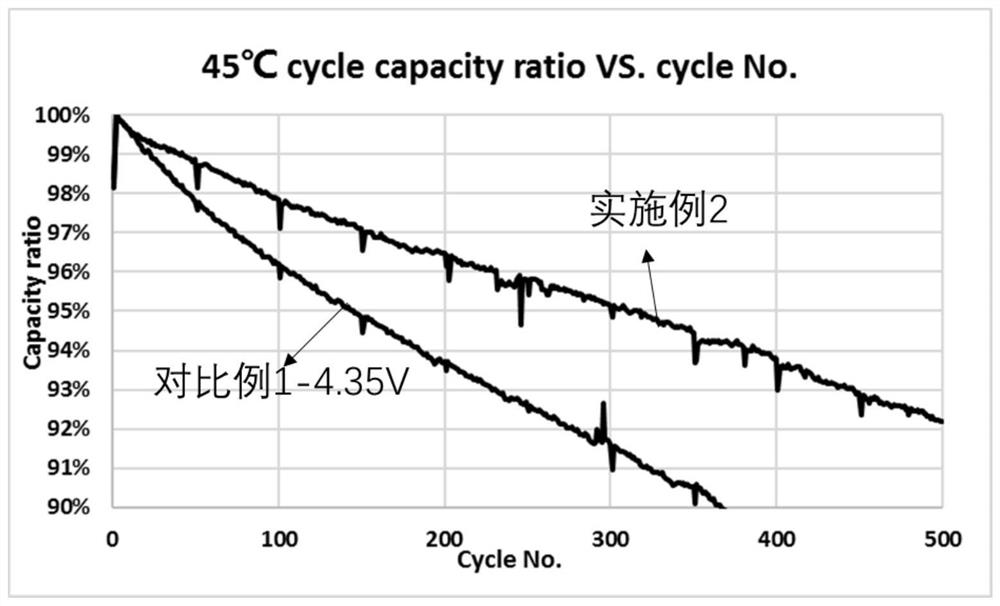

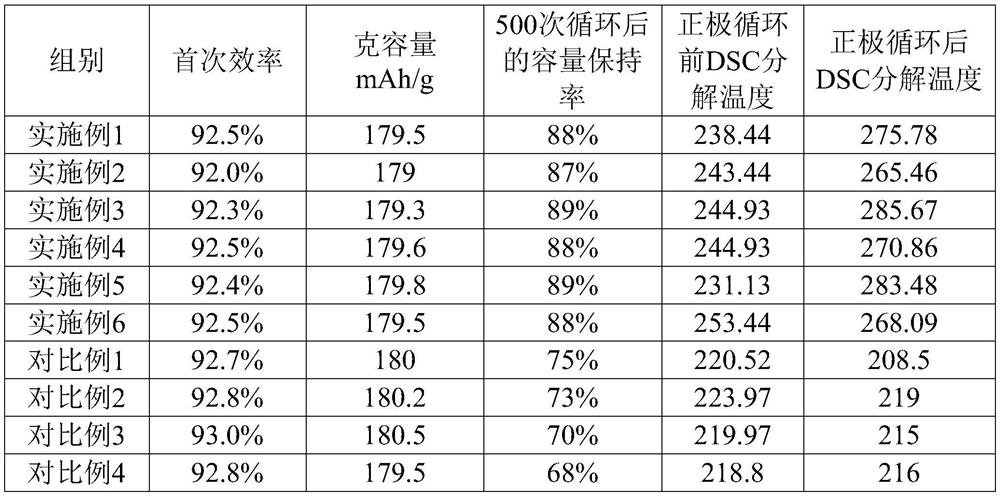

Cathode active material and preparation method thereof, and application thereof in lithium ion secondary battery

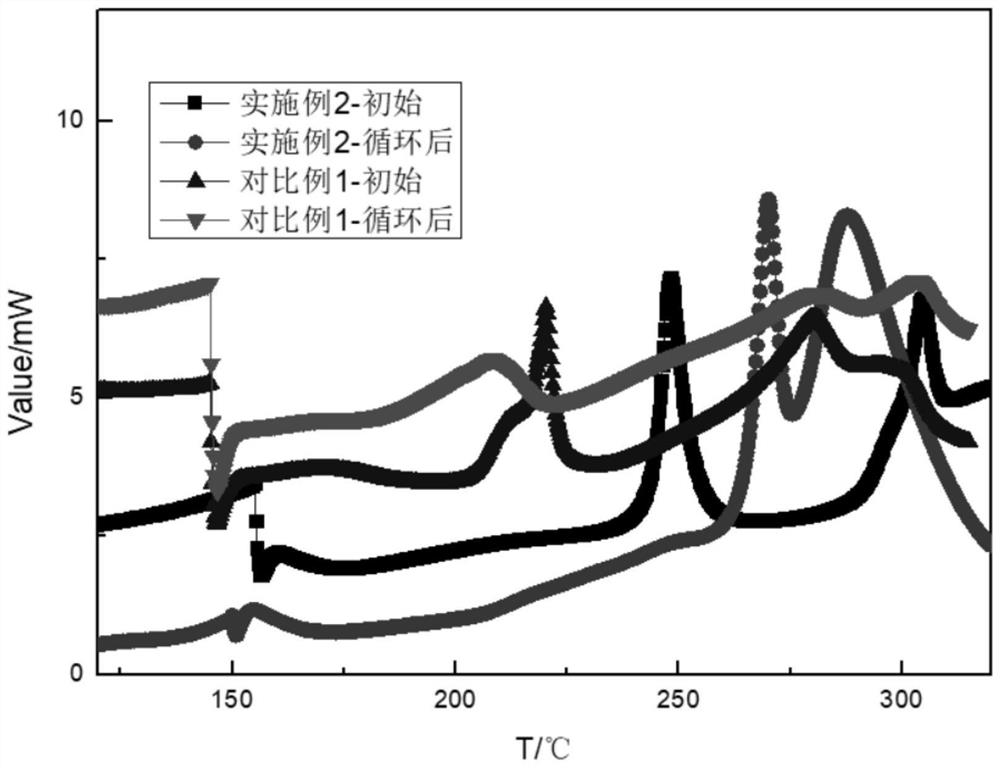

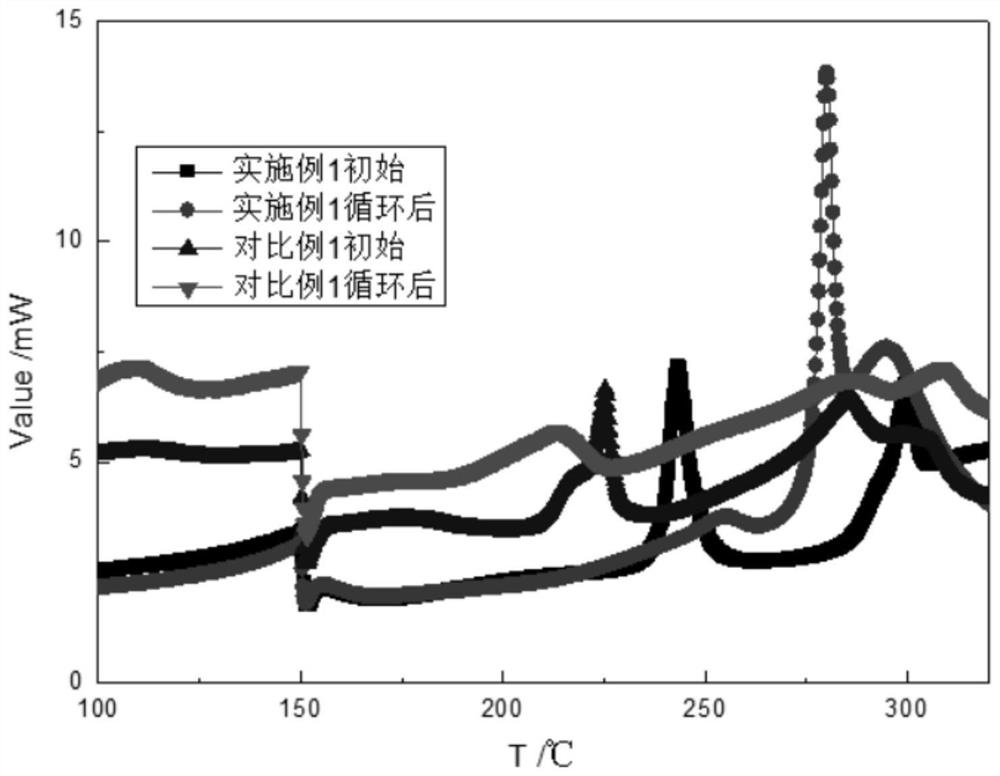

InactiveCN111900361AImprove cycle performanceReduce the degree of offsetSecondary cellsPositive electrodesBattery cellMaterials science

The invention provides a cathode active material and a preparation method thereof and application thereof in a lithium ion secondary battery. By introducing the high-voltage lithium cobalt oxide cathode active material into the lithium ion secondary battery, the cycle performance of the battery can be effectively improved, and meanwhile, along with the cycle of the lithium ion secondary battery, the DSC exothermic peak appearance temperature of the high-voltage lithium cobalt oxide cathode active material shifts to a lower temperature, but the shift degree is lower.

Owner:ZHUHAI COSMX BATTERY CO LTD

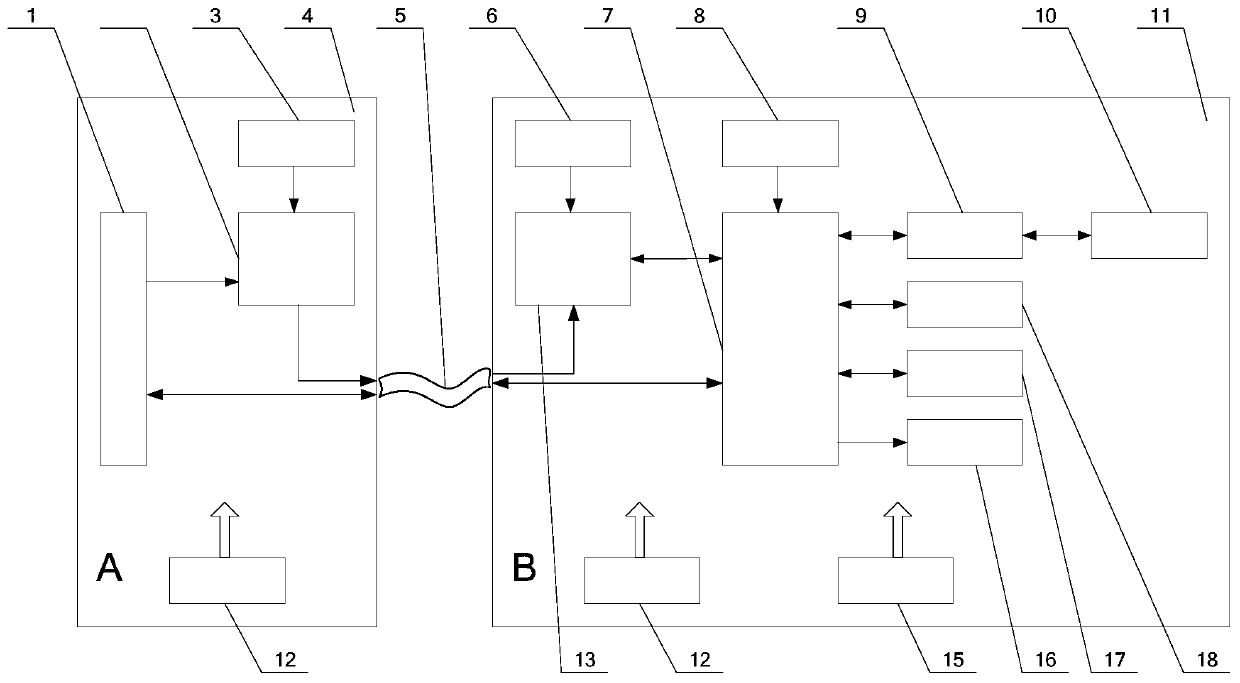

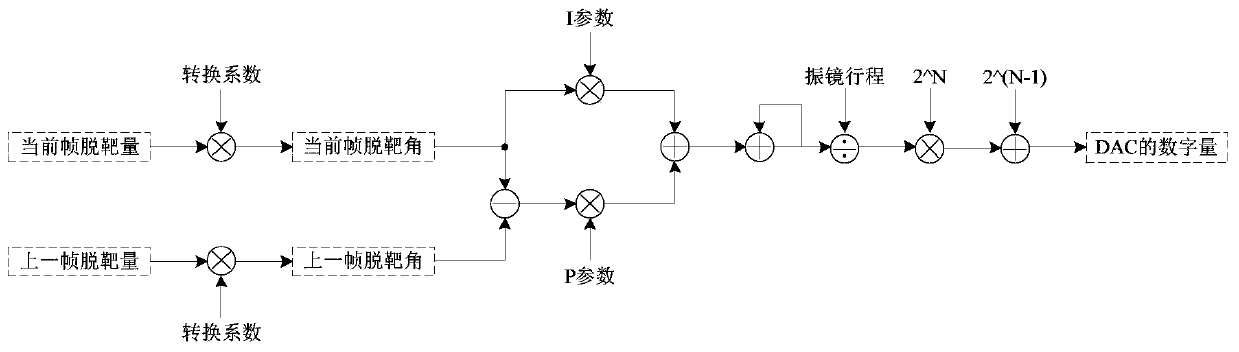

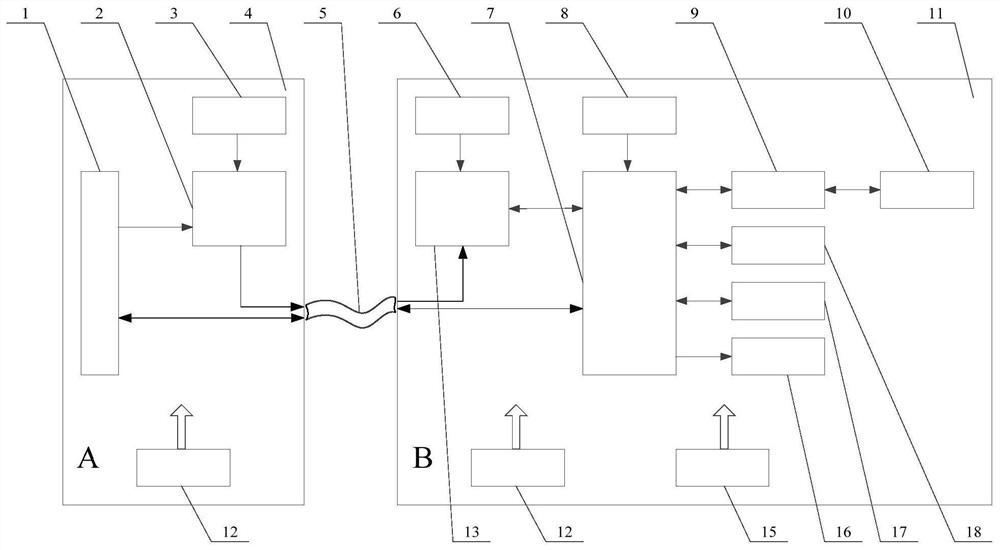

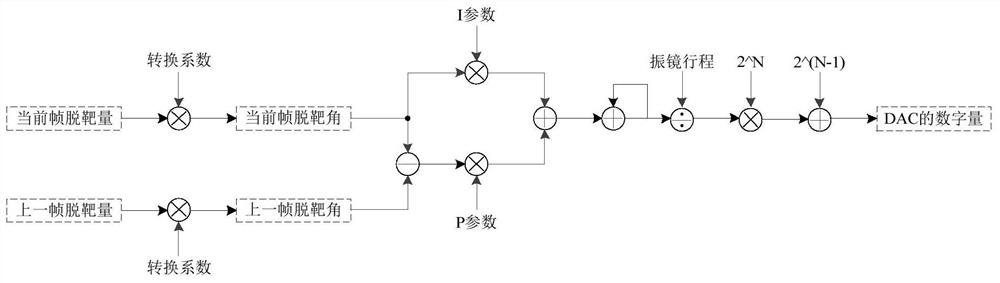

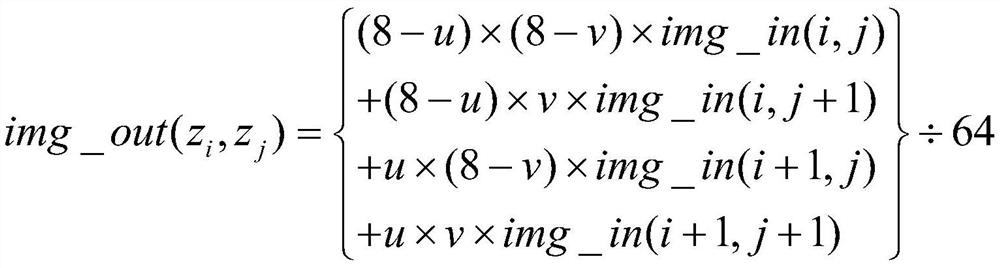

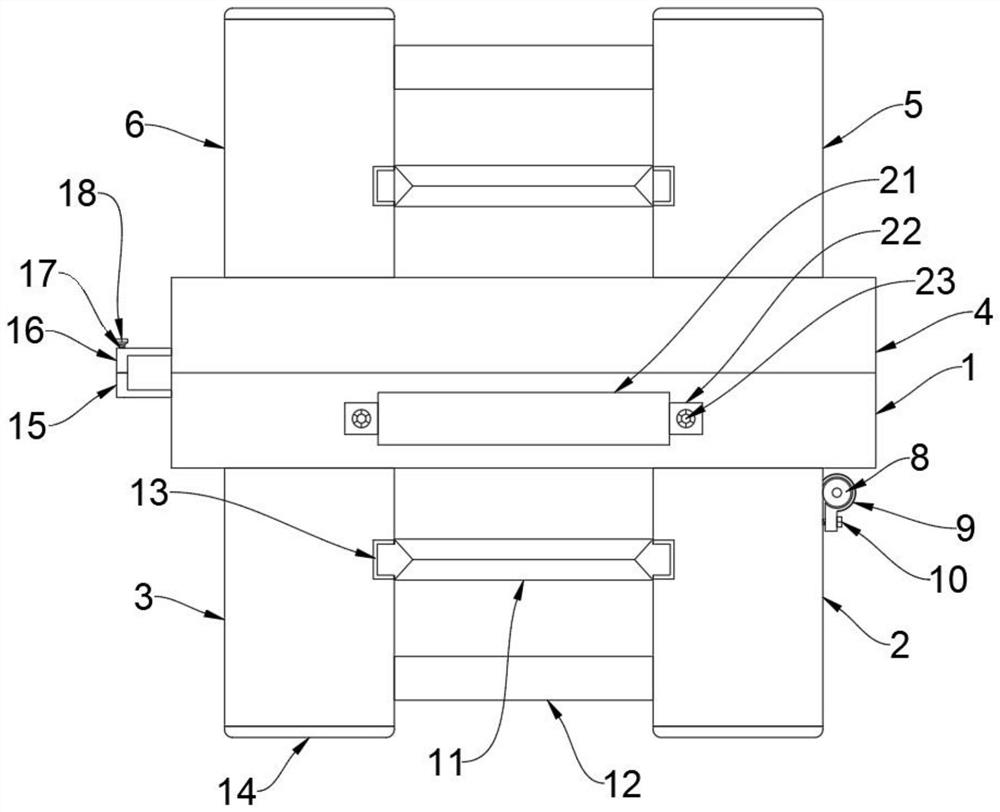

Target extraction and tracking camera and method for inter-satellite laser communication PAT system

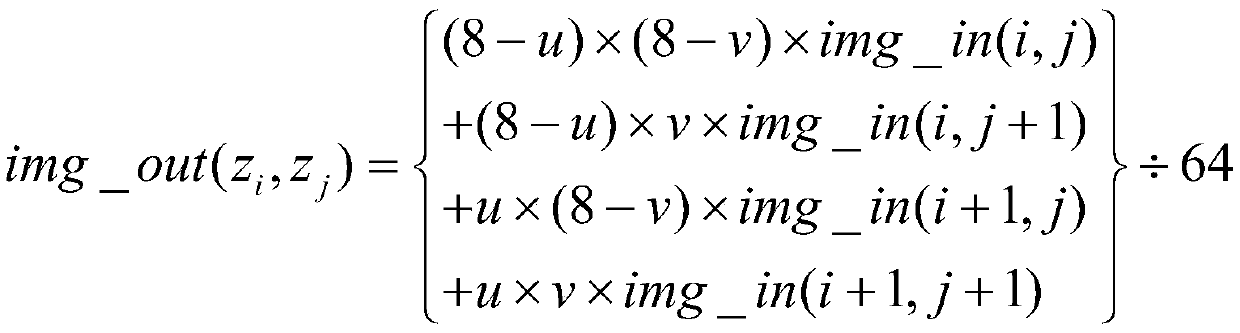

ActiveCN111211838AReduce off-target delayIncreased closed-loop control bandwidthTelevision system detailsColor television detailsInfrared detectorData processing

The invention discloses a target extraction and tracking camera and method of an inter-satellite laser communication PAT system. The three functions of detector driving and data processing, target detection and extraction and galvanometer control tracking are integrally designed in the two aspects of software and hardware, the miss distance delay can be reduced, the closed-loop control bandwidth of the system is improved, and the tracking precision of the PAT system is further improved. The basic working principle of the camera is as follows that: a short-wave infrared detector receives fine beacon light, detection and output of the fine beacon light are completed under the excitation of analog voltage and a digital time sequence of an FPGA chip, and an output signal is processed by an amplifying circuit and an analog-to-digital conversion circuit to form a digital image signal to enter the FPGA chip. Digital image data are subjected to a series of processing such as preprocessing, high-precision light spot extraction and galvanometer control in the FPGA chip, digital quantity is output to the digital-to-analog converter to generate control voltage, and finally a fine tracking galvanometer is controlled to complete high-precision and low-delay fine beacon light tracking.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

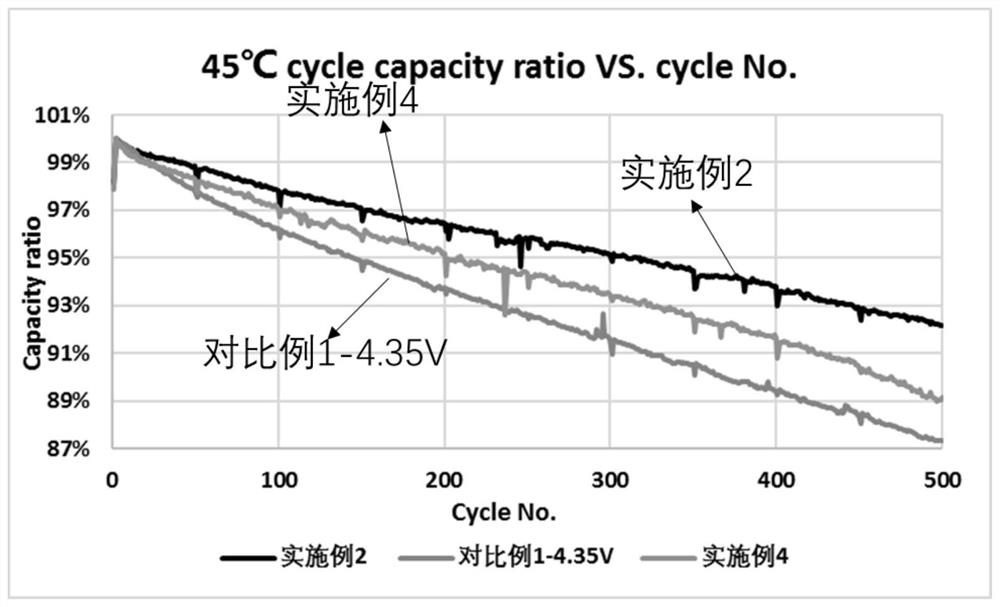

High-voltage lithium cobalt oxide positive electrode active material and preparation method and application thereof

InactiveCN111900359AImprove discharge capacityImprove thermal stabilityPositive electrodesElectrolytic agentHigh concentration

The invention provides a high-voltage lithium cobalt oxide positive electrode active material and a preparation method and application thereof. The high-voltage lithium cobalt oxide positive electrodeactive material has a core-shell structure, and a precursor Me3O4 containing Al and Z-doped cobalt is used as a raw material, wherein both the Al element and the Z element replace cobalt ions, so that the stability of the layered structure in the charging and discharging process is guaranteed, and frequent conversion between a layered hexagonal system and a spinel monoclinic system in the charging and discharging process of lithium cobalt oxide is avoided. Meanwhile, by means of a shell coating means formed on the surface, decomposition reaction caused by direct contact between electrolyte and high-concentration tetravalent cobalt ions on the surface of the positive electrode and dissolution and gas release of the cobalt ions in the electrolyte are avoided, and potential safety hazards caused by collapse of a local structure of the surface layer of particles along with increase of the dissolution amount of the cobalt ions on the surface layer are avoided; and corrosion of HF generatedby reaction of the electrolyte and a small amount of water in the lithium cobalt oxide core structure to a positive electrode active substance can be avoided.

Owner:ZHUHAI COSMX BATTERY CO LTD

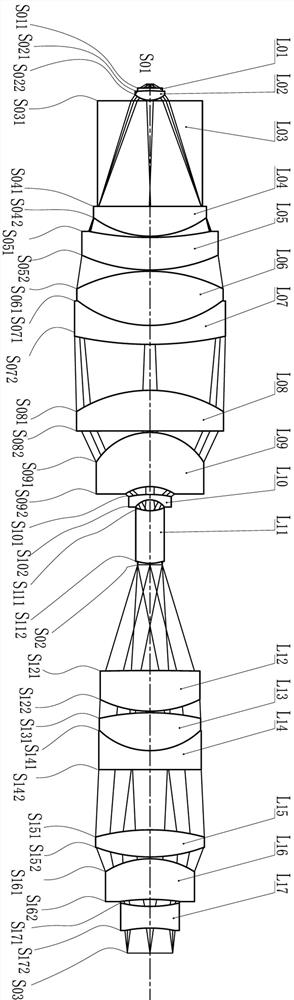

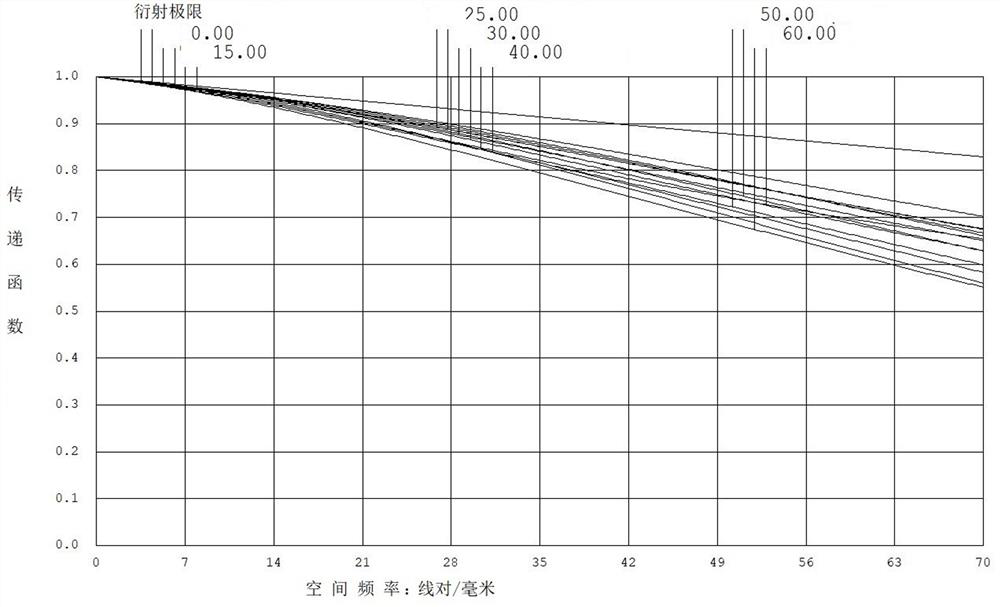

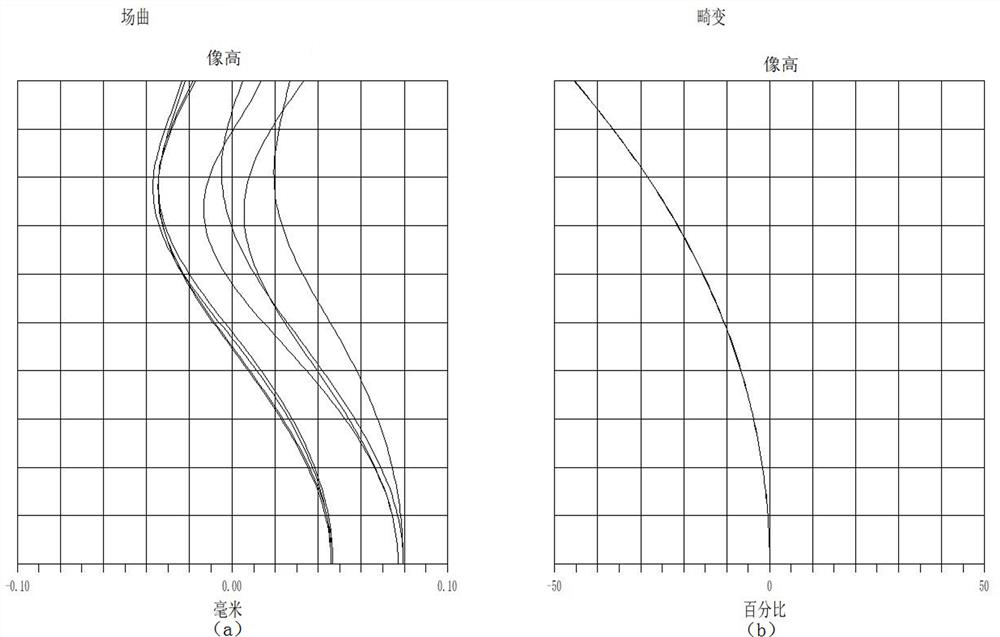

Wide-angle projection lens for optical waveguide AR lens detection

ActiveCN114089508AHigh coincidenceImprove energy utilizationOptical light guidesExit pupilOphthalmology

The invention discloses a wide-angle projection lens for optical waveguide AR lens detection, which sequentially comprises a front lens group, a diaphragm opening and a rear lens group from top to bottom. The front lens group projects the diaphragm opening to the foremost end of the lens to form a virtual diaphragm; the front lens group sequentially comprises a turning prism, a fourth lens, a fifth lens, a seventh lens, an eighth lens, a ninth lens and a tenth lens from top to bottom; and the multiplying power beta of the front lens group is more than 1.8 and less than 3.0. According to the wide-angle projection lens, the entity diaphragm in the lens is led out of the lens to become a virtual diaphragm, the contact ratio of exit pupils is smaller than 0.1 mm through correction of diaphragm aberration, the exit pupils are overlapped with the diaphragm of AR glasses to be measured, subject matter of the same size can be provided for different view fields, and the coupling energy utilization rate is improved; and meanwhile, the physical interference of the projection lens and the receiving lens in the transverse dimension during the same-side detection of the large-angle object to be detected is solved.

Owner:MOONLIGHT (NANJING) INSTR CO LTD

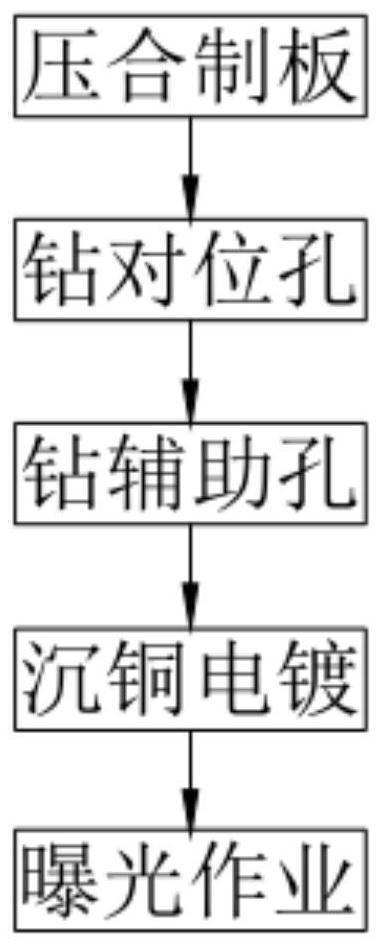

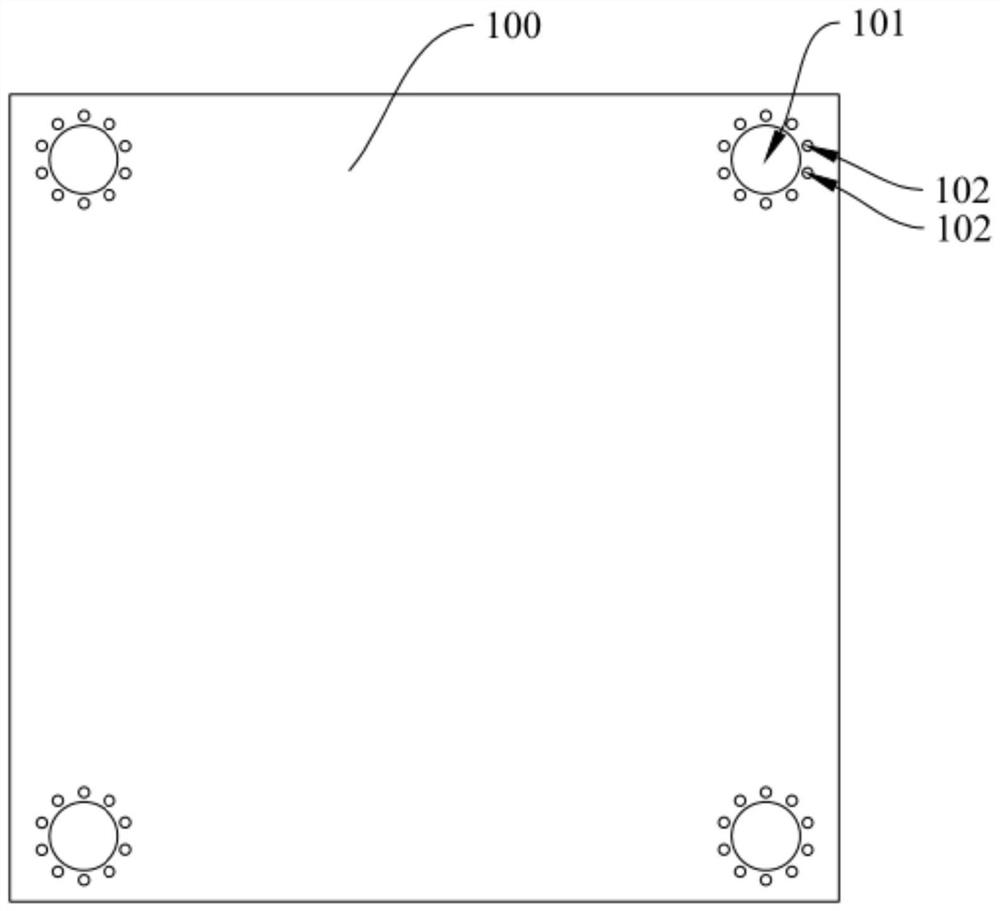

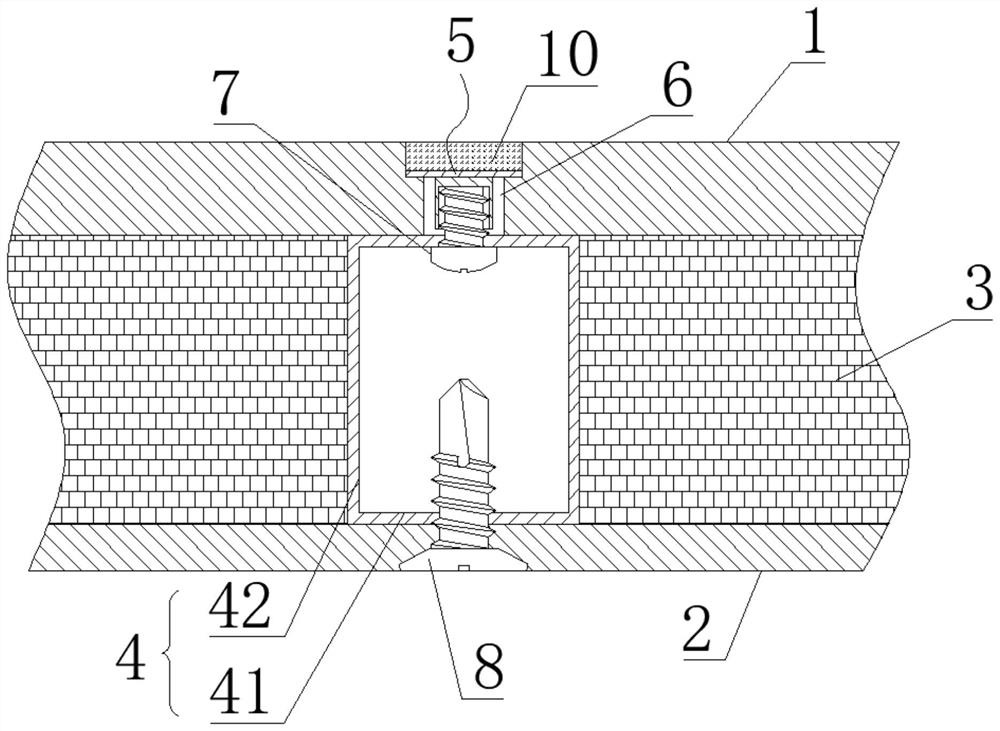

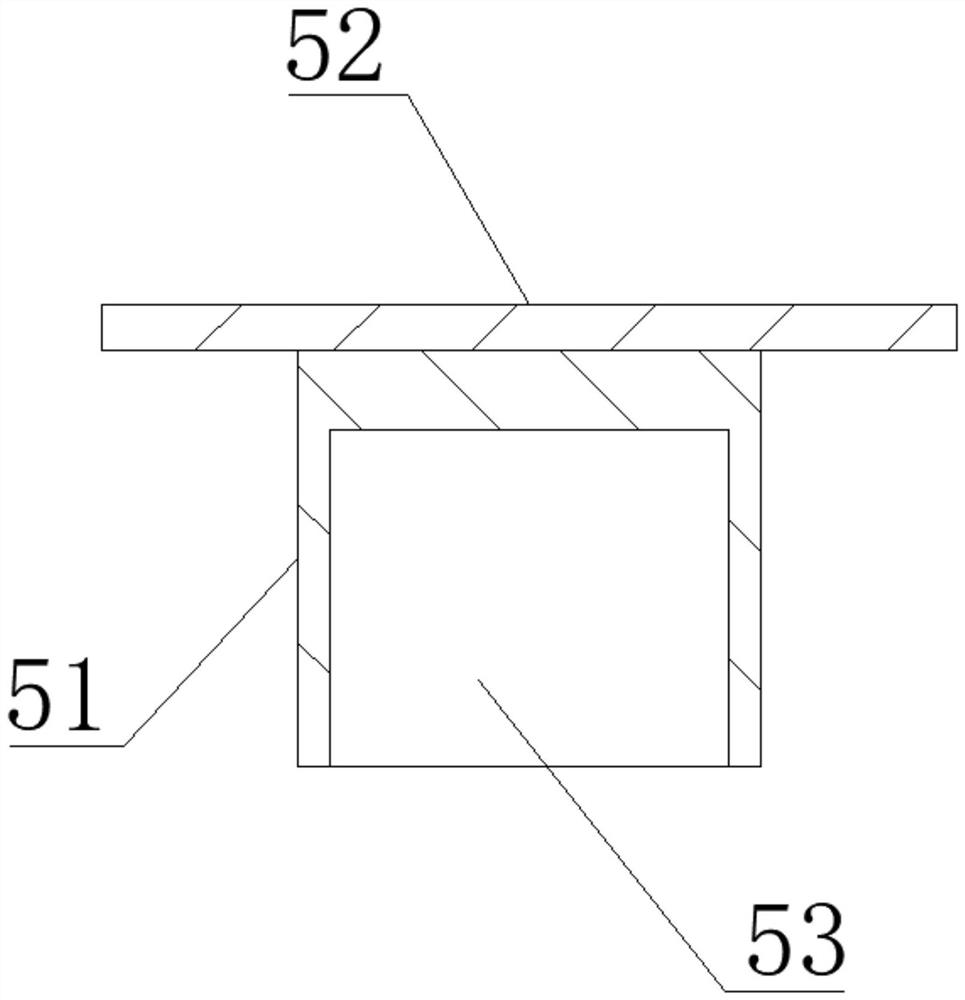

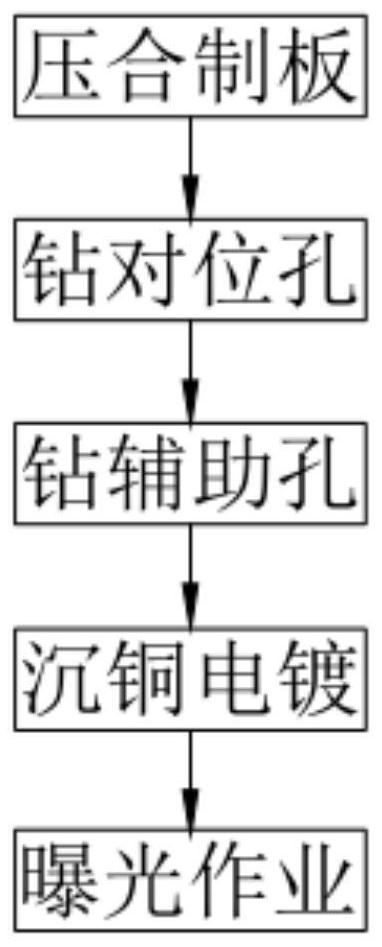

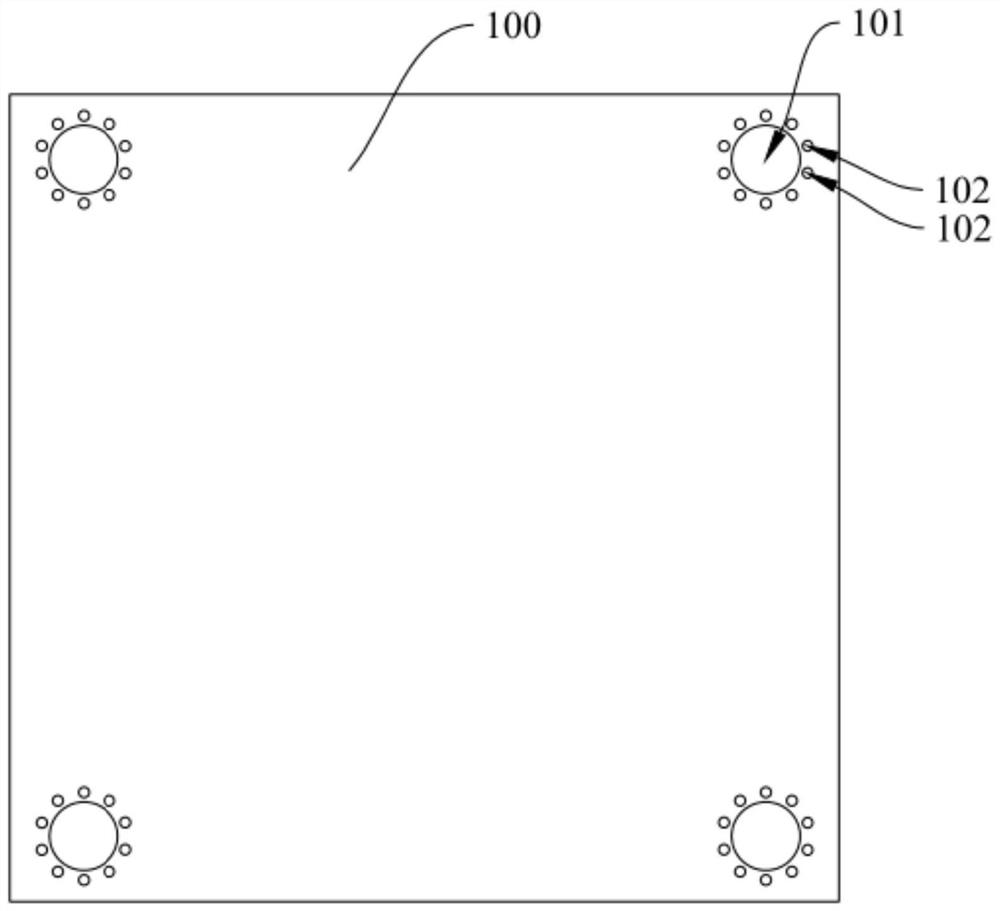

Circuit board manufacturing method

ActiveCN112930033AImprove production yieldImprove reliabilityPrinted circuit manufactureCopper foilMechanical engineering

The invention relates to the field of circuit board manufacturing, and provides a circuit board manufacturing method, which comprises the steps of press-fit board manufacturing, alignment hole drilling, auxiliary hole drilling, copper deposition and electroplating, and exposure operation. In the alignment hole drilling step, at least three alignment holes are drilled in the peripheral edge of the plate surface of the pressed blank plate; in the auxiliary hole drilling step, at least one auxiliary structure is drilled on the peripheral side of each alignment hole, and the auxiliary structure comprises a plurality of auxiliary holes arranged in a circumferential array; in the copper deposition and electroplating step, copper deposition and electroplating are carried out on the alignment holes and the auxiliary holes; and in the exposure operation step, the center of each alignment hole is captured as an alignment reference, and exposure treatment is carried out on the surface, deviating from the mother board, of the copper foil. According to the circuit board manufacturing method, by improving the deviation degree of the centers of the alignment holes before and after electroplating, layer-by-layer guarantee is achieved, the interlayer alignment precision is improved, the interlayer alignment precision of the multi-layer circuit board is finally improved, the alignment deviation is effectively reduced, and therefore the production yield and the quality reliability of the multi-layer circuit board can be effectively improved.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

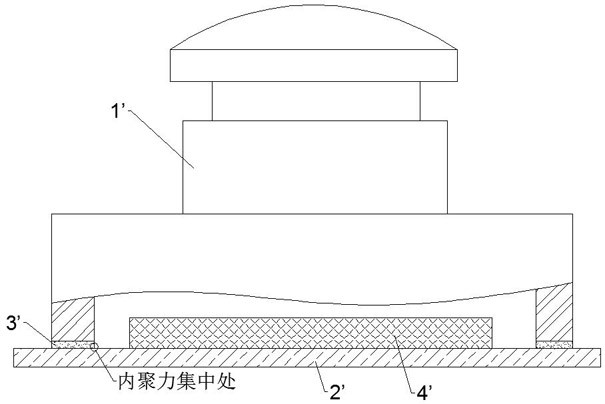

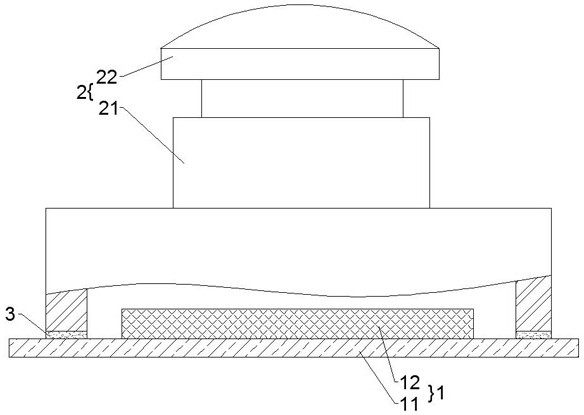

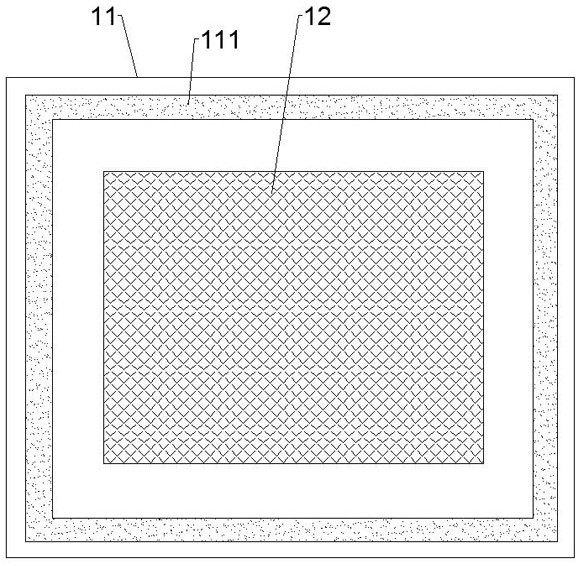

Manufacturing method of heat preservation and decoration integrated plate

PendingCN114412111AReduce the degree of offsetImprove connection stabilityCovering/liningsPunchingHeat conservation

The invention discloses a manufacturing method of a heat preservation and decoration integrated board, and belongs to the technical field of heat preservation and decoration, and the manufacturing method of the heat preservation and decoration integrated board comprises the following steps: S1, panel punching: punching a T-shaped through hole in a panel, S2, pre-burying a nut column: putting the nut column into the T-shaped through hole, S3, filling glue for hole patching, S4, panel sanding, and S5, veneer manufacturing. And S6, pressing and effective connection are conducted, specifically, the inner side faces of the face plate and the back plate are glued, the heat preservation layer and the reinforcing pieces are arranged between the face plate and the back plate, pressing is conducted, and the reinforcing pieces, the face plate and the back plate are fixed through threaded fasteners before pressing and / or after pressing, so that effective connection is formed. According to the manufacturing method of the heat preservation and decoration integrated plate, connection between the face plate and the back plate is reinforced through the reinforcing pieces, good reliability and safety are achieved, the face plate is provided with the T-shaped penetrating holes, the nut columns are embedded, good connection stability is achieved, and production and machining are facilitated.

Owner:固克节能科技股份有限公司

Method for reducing steel belt running deviation of continuous annealing and coating machine set

InactiveCN104232880AReduce the degree of offsetReduce the deviation rateFurnace typesHeat treatment process controlLoop lengthWeld seam

The invention discloses a method for reducing steel belt running deviation of a continuous annealing and coating machine set, belonging to the field of metallurgy. The method comprises the following steps: when entrance welding is performed, stopping an uncoiling machine; when the loop length is reduced to 15% and a welded seam is fed in a furnace, lifting the uncoiling machine to recover operation, and enabling a furnace section to operate at constant speed normally; when the uncoiling speed is higher than the speed of the furnace section, performing loop charging operation, charging the loop length to be 35% of the total loop length, then stopping the loop charging operation, and keeping that the uncoiling speed is consistent with the speed of the furnace section to perform normal operation; when 200m of the steel belt is left on the uncoiling machine, restarting an entrance loop to perform the loop charging operation, wherein the maximum change amount of the loop length is not more than 25%, and the entrance loop tension is 14N / mm<2>; and until a welding operation needs to be performed, repeating the operations after the entrance welding ends. By adopting the method disclosed by the invention, the deviation degree of strip steel in the entrance loop can be effectively reduced, the friction force of the strip steel to a supporting roller of a loop trolley can be increased, the deviation speed of the strip steel can be reduced, and the running deviation edge rolling rate of the machine set can be reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

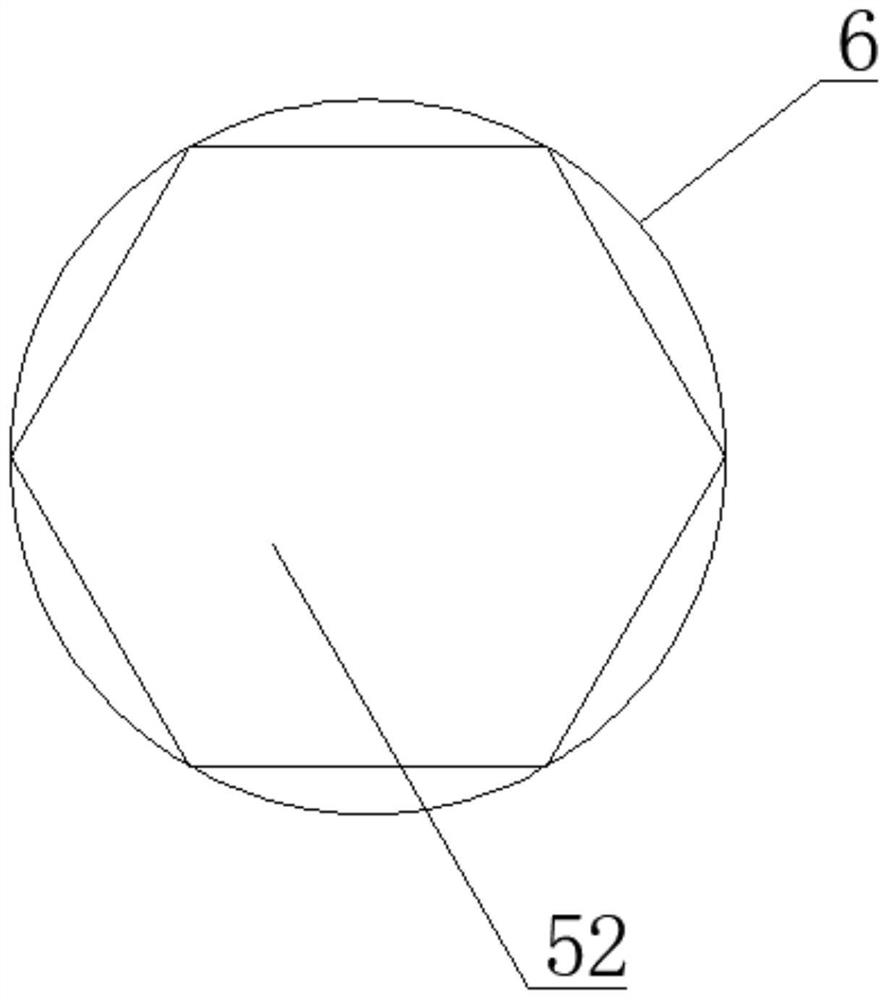

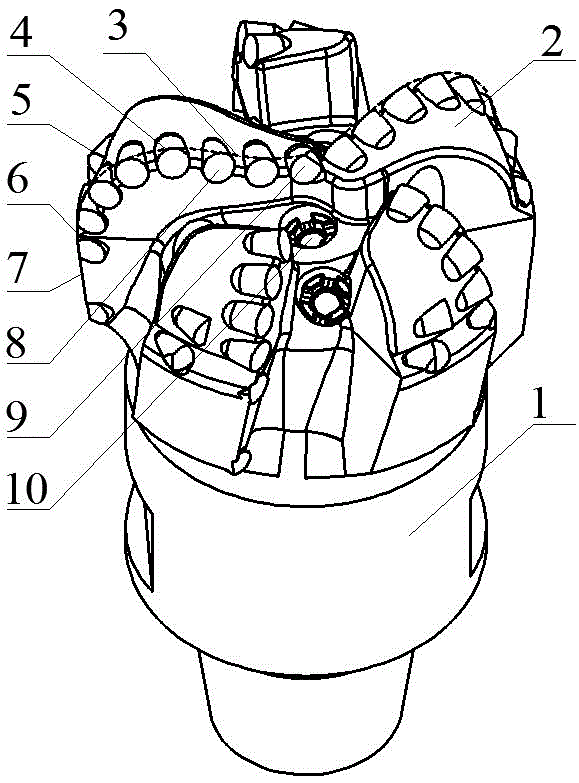

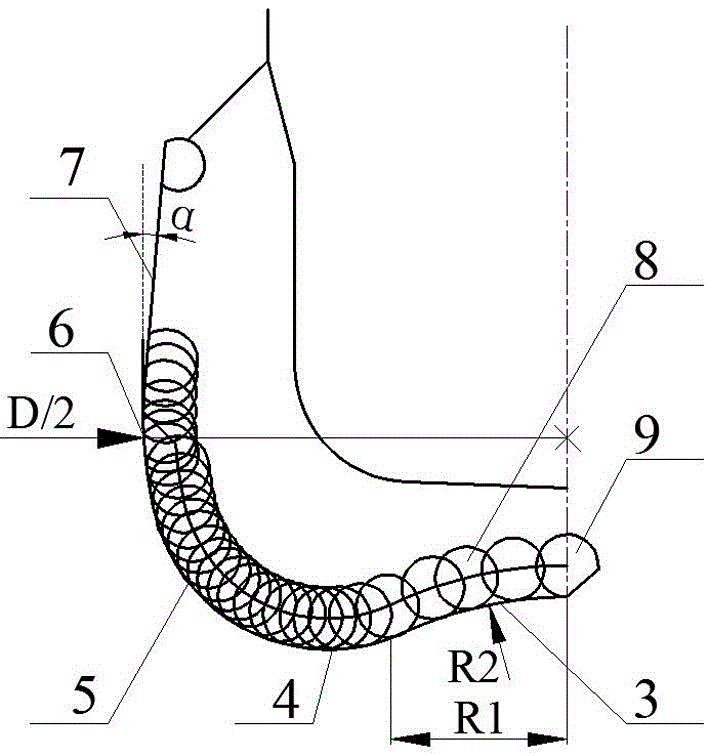

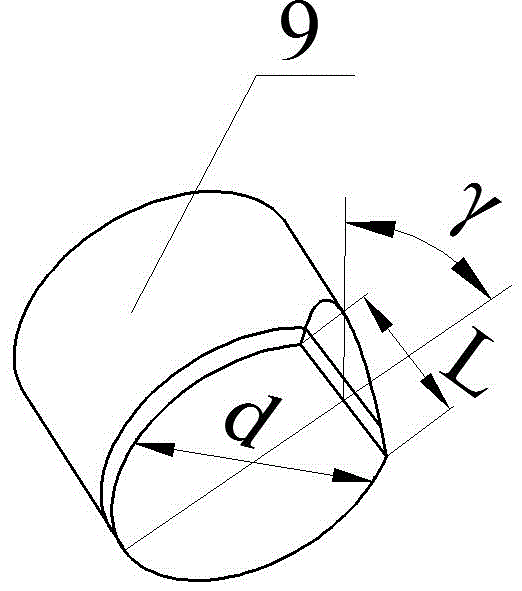

PDC drill bit with directional easy controllability enhancing performance

InactiveCN105464599ALow steering resistanceImprove fitDrill bitsPolycrystalline diamondControllability

The invention relates to a PDC (Polycrystalline Diamond Composite) drill bit with directional easy controllability enhancing performance. The PDC drill bit comprises a drill bit body, a crown part and cutting teeth, wherein a plurality of cutting teeth are arranged on the contour line of the crown part; the curved surface contour of the crown part of the drill bit is formed by sequentially and smoothly connecting a core part, a nose part, an outer side, a shoulder part and a gage section; the core part of the drill bit is a concave spherical surface; the cutting tooth near the center part of the drill bit is the cut-edge tooth; one intersection point of the cut edge of the cut-edge tooth with the excircle is positioned in the axial line of the drill bit body 1; the contour corresponding to the shoulder of the drill bit is of a spherical surface structure; and the contour corresponding to the gage section is of a conical structure. The PDC drill bit has the advantages that in the directional drilling and deflecting process, the fit of the core part of the drill bit with the shaft bottom is good; the steering resistance of the core part and the friction resistance of the gage are small; and the directional track deviation degree can be reduced through enhancing the directional operation and control performance of the drill bit and improving the shaft wall quality, so that the construction quality of directional drilling is improved.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

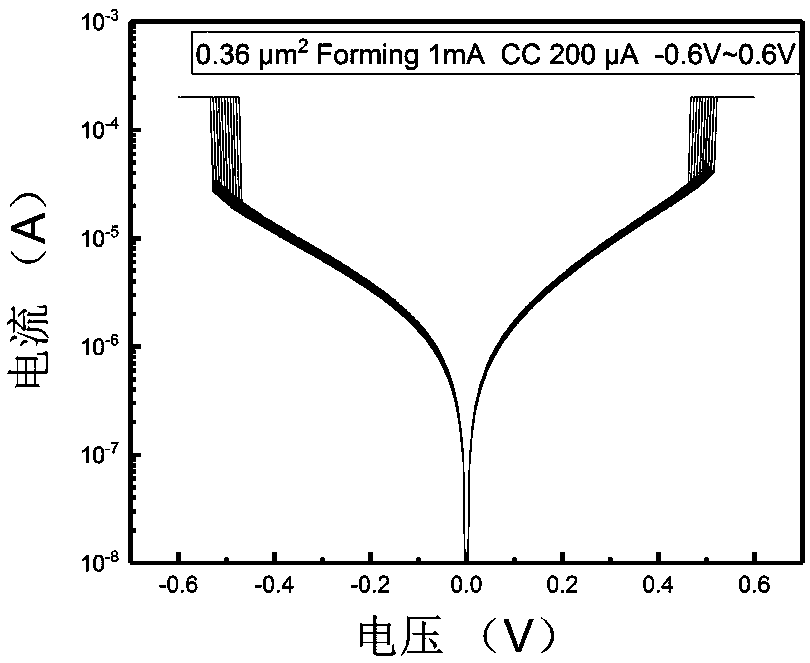

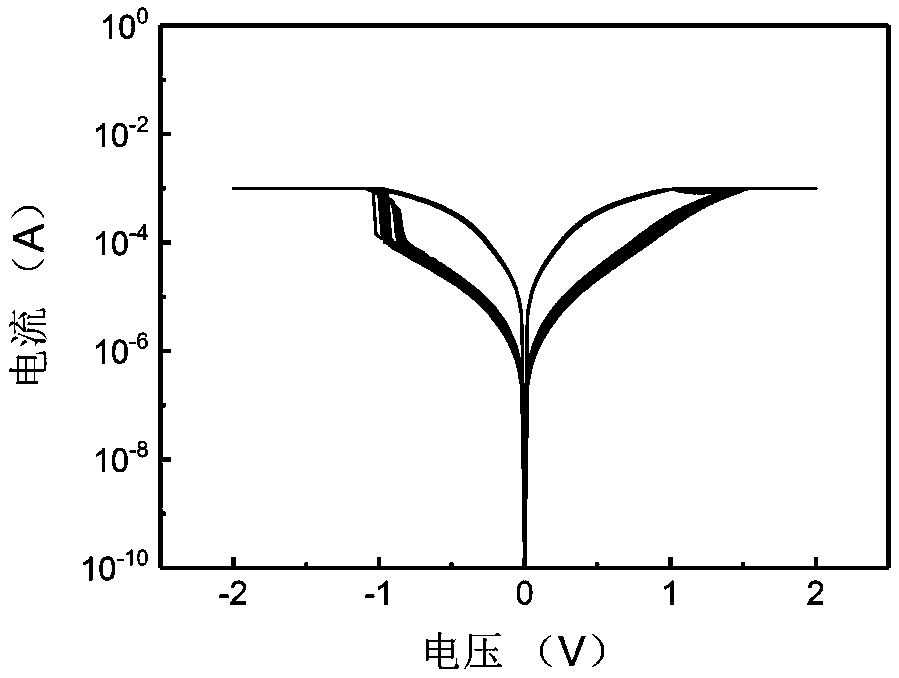

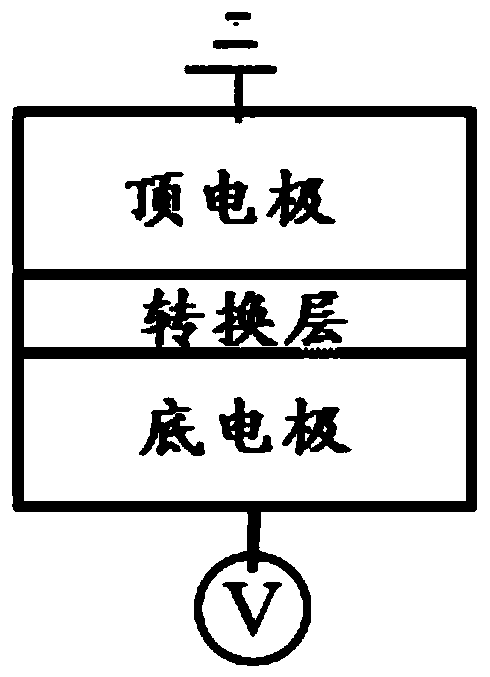

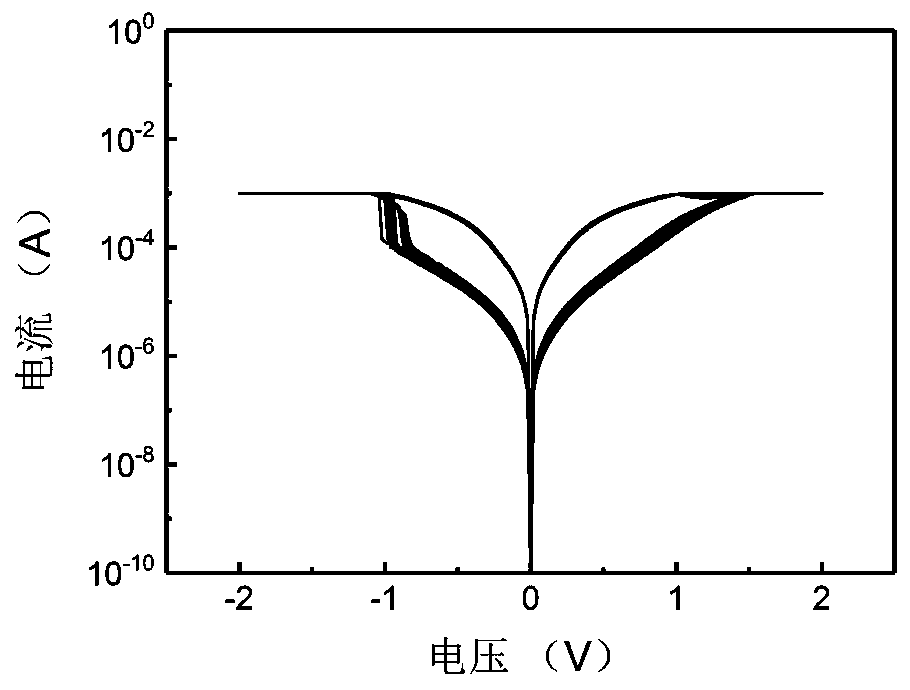

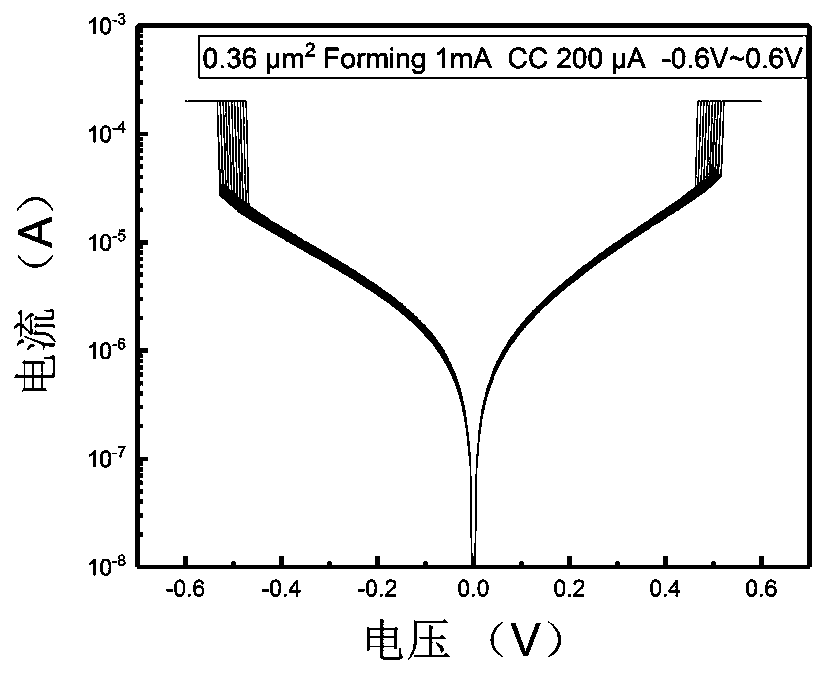

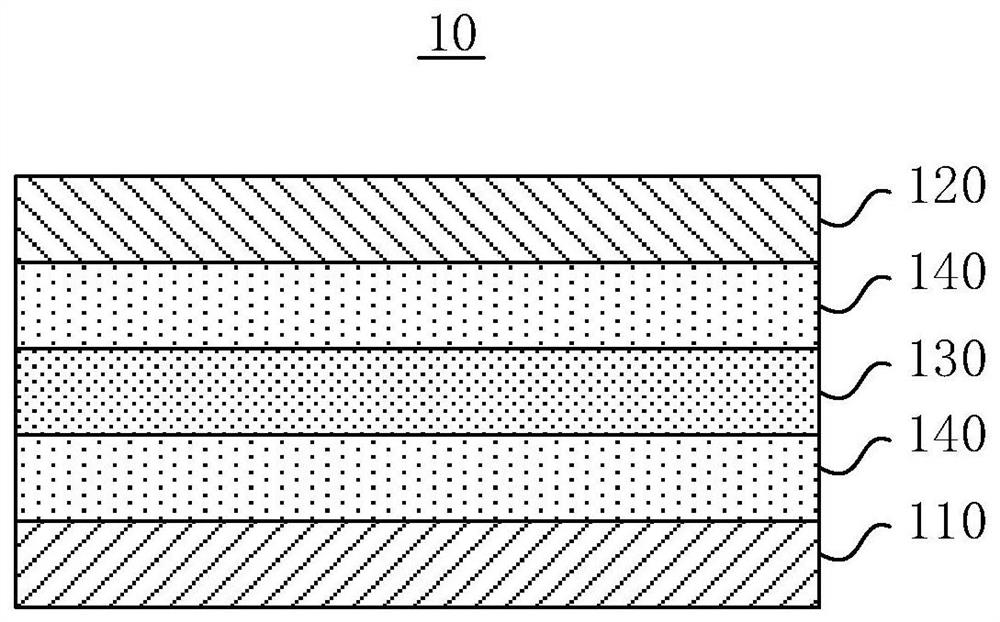

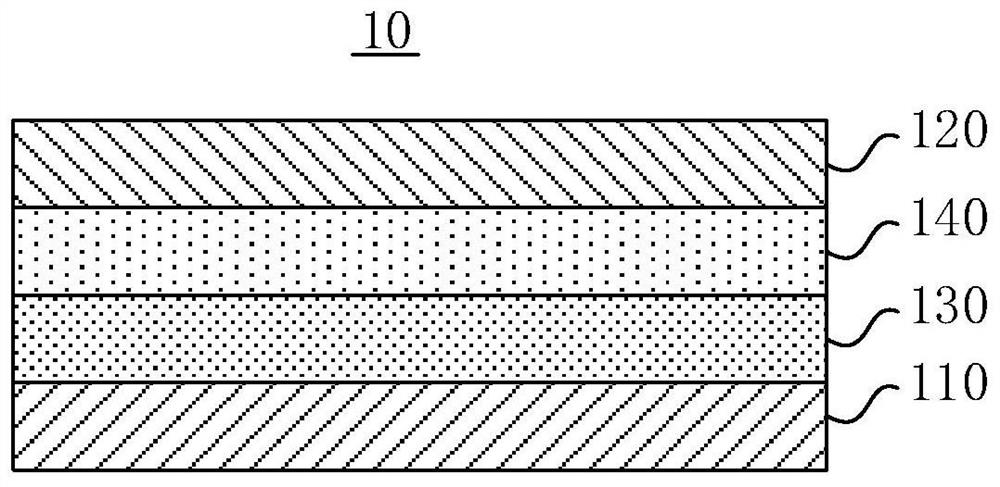

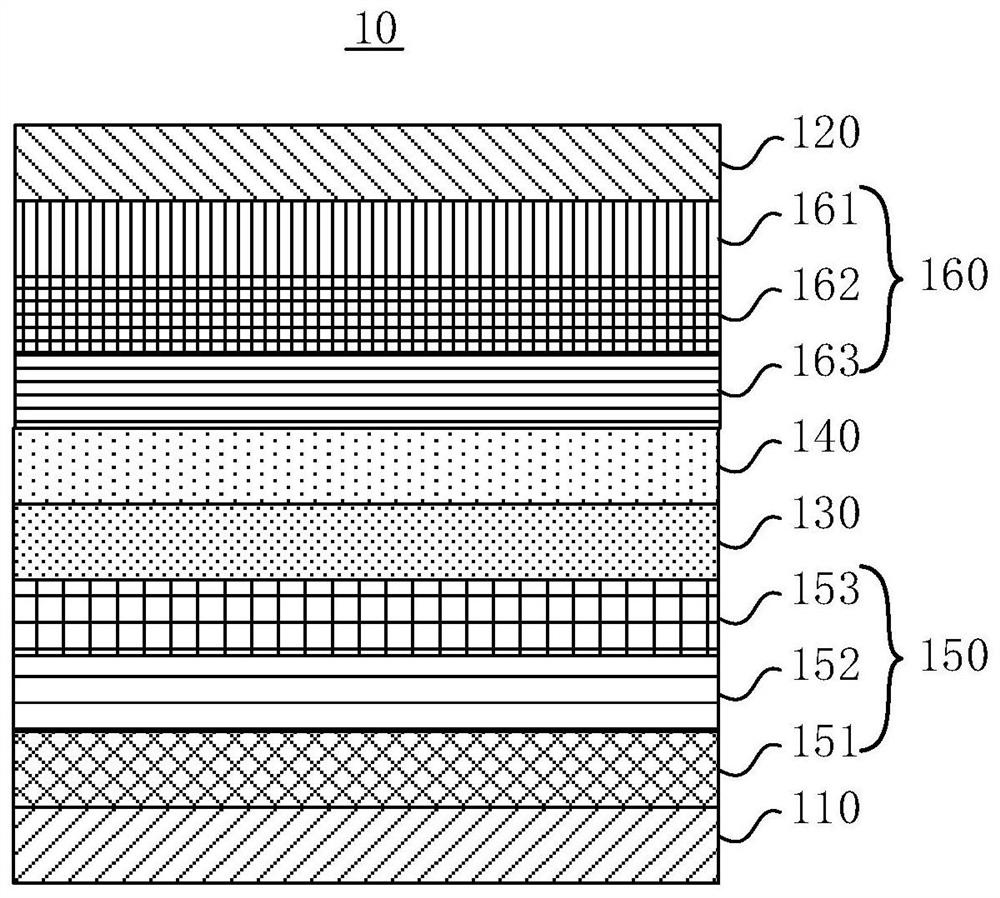

Device with storage and gating functions and preparation method thereof

ActiveCN108598257AIncrease storage windowReduce the degree of offsetElectrical apparatusHigh resistanceElectrical resistance and conductance

The invention provides a device with storage and gating functions which comprises a bottom electrode, a conversion layer and a top electrode sequentially from downside to upside; the bottom electrodeis TiN or conductive glass; the conversion layer is made of niobium oxide; and the top electrode is tungsten. The device with the storage and gating functions is composed of the niobium oxide which serves as the conversion layer, the TiN or conductive glass which serves as the bottom electrode, and the metal tungsten which serves as the top electrode. The experimental results show that the deviceprovided by the invention has a gating function in the presence of big current limitation and has a resistance change performance (storage performance) in the presence of small current limitation; thedevice also has excellent stability as the deviation degree of the obtained curve is very small after the device is subjected to circular test for 100 turns in the gating and resistance change performance test; and the device also has a relatively big storage window as the resistance value of a high-resistance resistor is 10 greater than that of a low-resistance resistor in the resistance changeperformance test.

Owner:HUBEI UNIV

A storage and gating dual-function device and its preparation method

ActiveCN108598257BIncrease storage windowReduce the degree of offsetElectrical apparatusElectrical resistance and conductanceCurrent limiting

The invention provides a dual-function device for storing and gating, which includes a bottom electrode, a conversion layer and a top electrode from bottom to top, the bottom electrode is TiN or conductive glass, the conversion layer is niobium oxide, and the The top electrode is tungsten. The invention uses niobium oxide as the conversion layer, uses TiN or conductive glass as the bottom electrode, and metal tungsten as the top electrode to form a device with dual functions of storage and gating. Experimental results show that the device provided by the present invention has gating performance when there is a large current limit, and has resistive switching performance (i.e. storage performance) when small current limiting; Simultaneously in the gating and resistive switching performance test, cycle test 100 circles, The deviation degree of the obtained curve is very small, indicating that it also has excellent stability; in the resistance switching performance test, the resistance value of the high-resistance state is greater than 10 than the resistance value of the upper low-resistance state, indicating that the device also has a large Storage window.

Owner:HUBEI UNIV

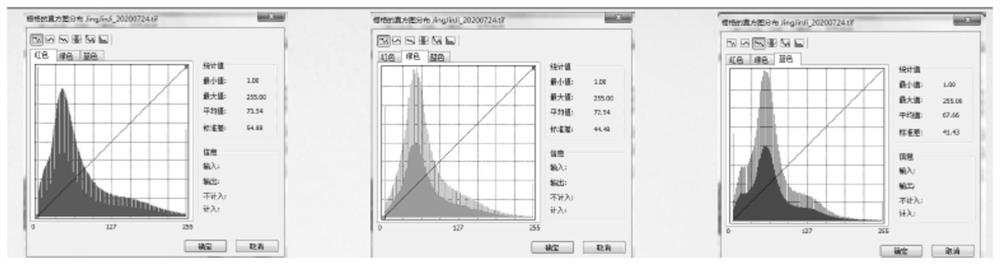

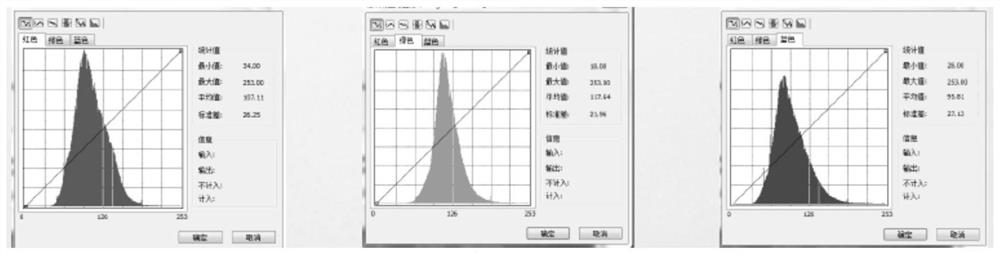

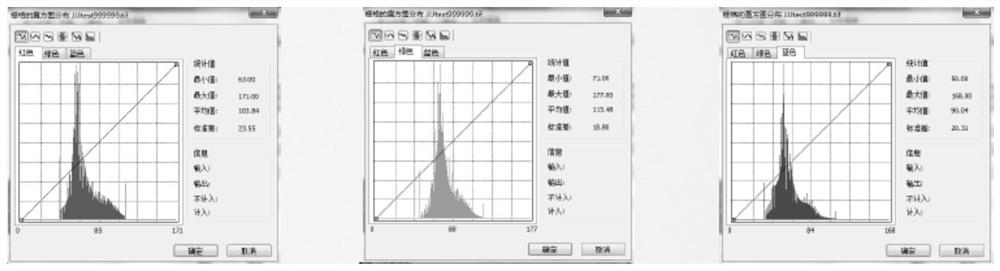

Remote sensing image color homogenizing method and system based on histogram matching, equipment and medium

PendingCN113706426AEasy to captureGray value brighteningImage enhancementImage analysisImage pairWave band

The invention provides a remote sensing image color homogenizing method based on histogram matching. According to the technical scheme, the preset number of first preset wavebands corresponding to the to-be-corrected image and the same number of second preset wavebands corresponding to the base image are obtained, the medians of the first preset wavebands and the second preset wavebands are calculated one by one, and the medians of the first preset wavebands and the medians of the second preset wavebands are aligned one by one. each first preset wave band is divided into a first unit set and a second unit set by taking the median of each first preset wave band as a reference; each second preset wave band is divided into a third unit set and a fourth unit set by taking the median of the second preset wave band as a reference; and the first unit set is extended into a range of a third unit set corresponding to the number of digits, and the second unit set is extended into a range of a fourth unit set corresponding to the number of digits.

Owner:中科星通(廊坊)信息技术有限公司 +2

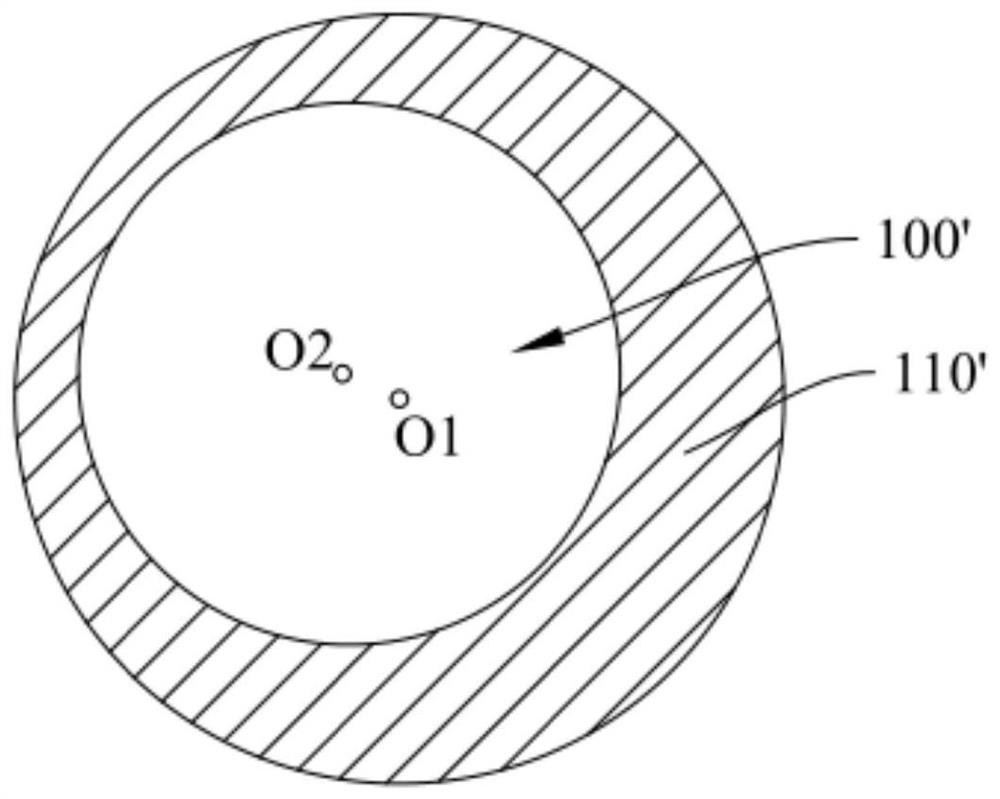

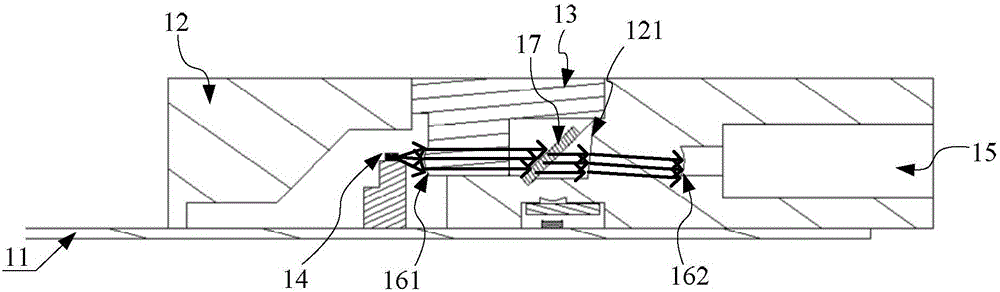

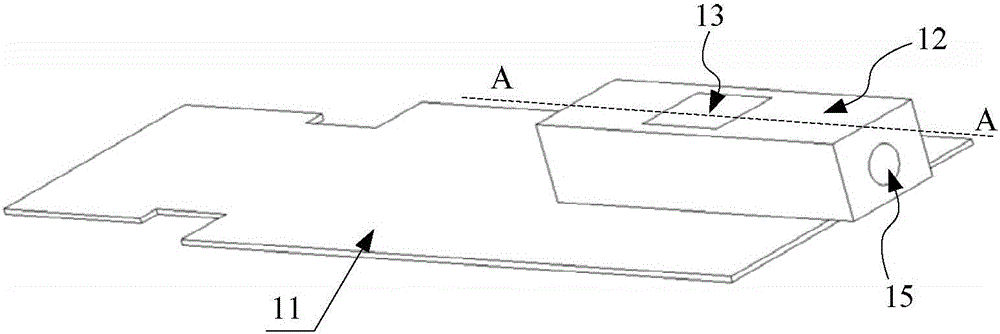

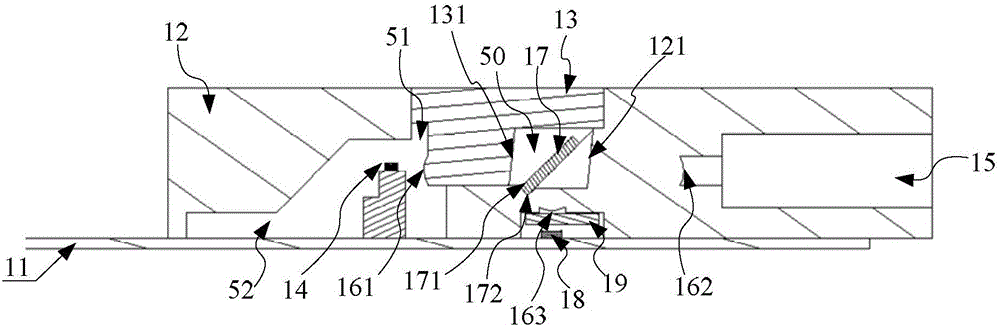

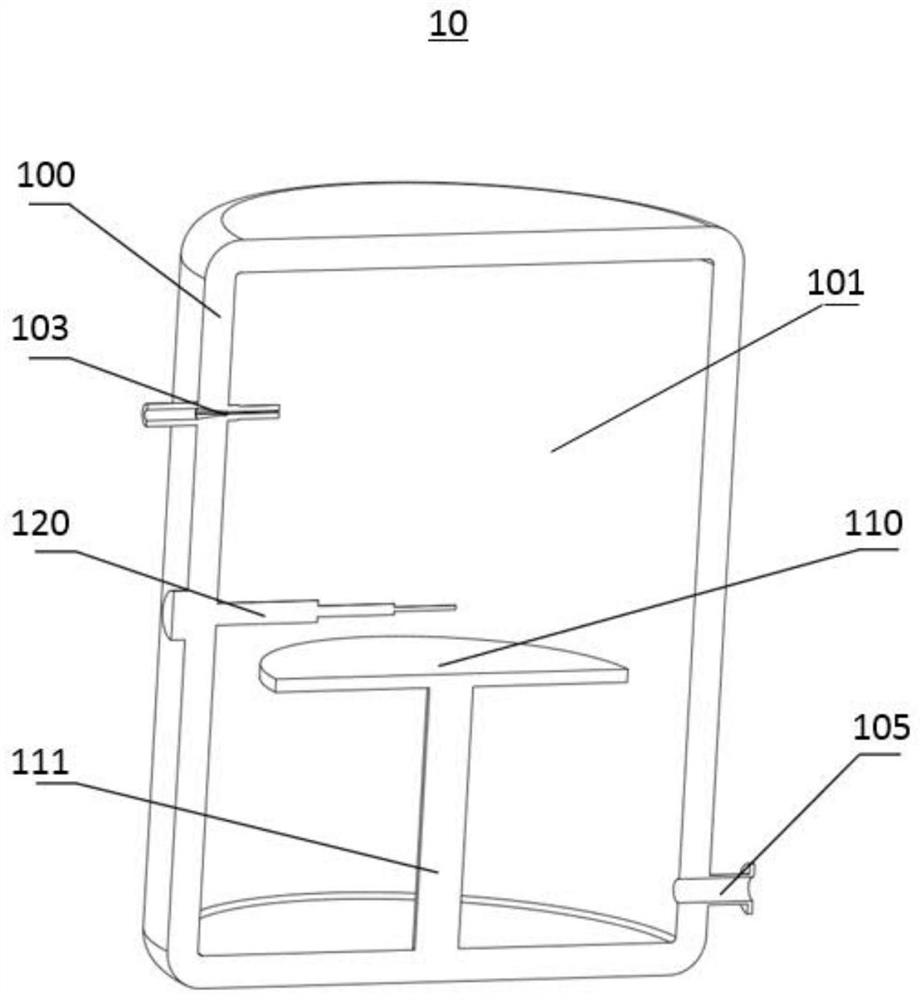

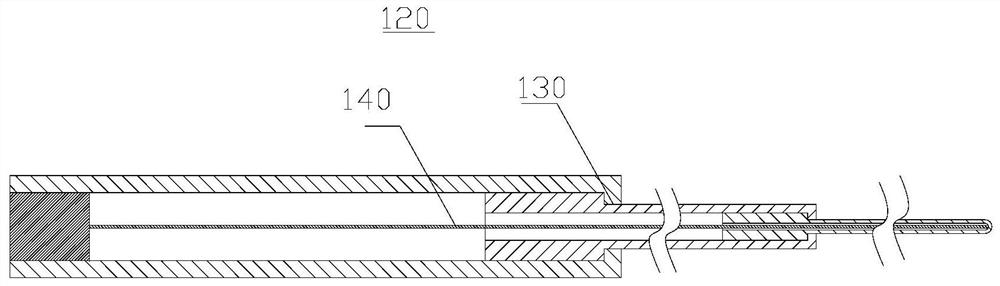

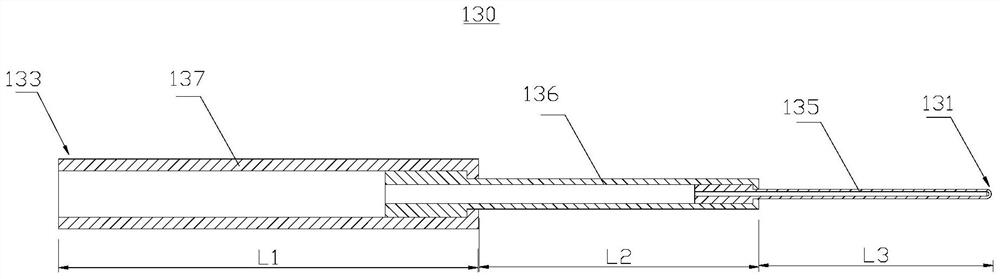

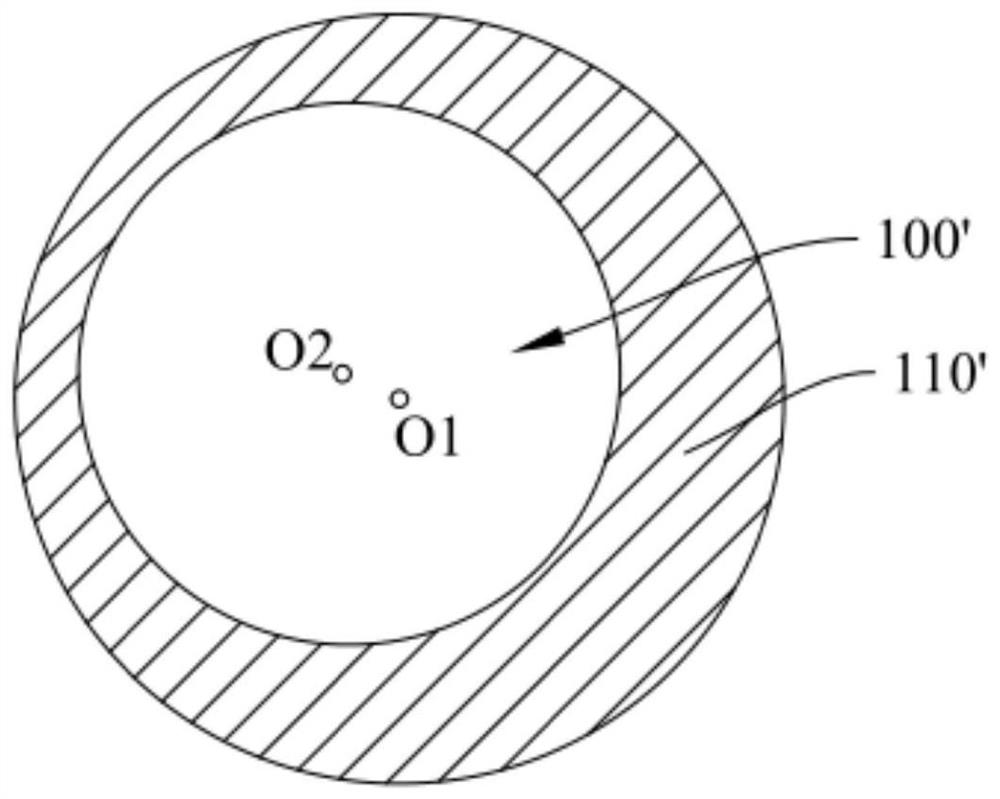

An optical module assembly and optical module

ActiveCN103995323BReduce the degree of offsetCoupling light guidesOptical ModuleOptical communication

The invention discloses an optical module assembly and relates to the field of optical communication. The optical module assembly is used for reducing optical axis deviation caused by reduction of the draft angle. The optical module assembly is used for coupling light emitted by a laser device into optical fibers and comprises a body element and an insertion element, the body element is provided with a first cavity, the insertion element is placed in the first cavity, a cavity is formed by the body element and the insertion element in a surrounded mode, at least one inner wall, through which the light passes, of the cavity is a draft inclined plane, and the light passes through the draft inclined plane and then rotates to the optical axis by a first deviation angle; the light module assembly is provided with a dimming inclined plane through which the light passes, and the light passes through the dimming inclined plane and then rotates to the optical axis by a second deviation angle; the first deviation angle and the second deviation angle are opposite in rotation direction.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

Temperature measuring device and chemical vapor deposition equipment

PendingCN114812862AAffect temperatureAvoid shockThermometer detailsRadiation pyrometryEngineeringChemical vapor deposition

The invention provides a temperature measuring device and chemical vapor deposition equipment, and relates to the technical field of temperature measurement. The temperature measuring device comprises a horizontally arranged multi-stage structure and a temperature measuring element. The multi-stage structure is provided with multi-stage sleeves detachably connected in the axial direction of the multi-stage structure, the multi-stage structure is provided with a first end and a second end which are opposite in the axial direction of the multi-stage structure, the first end is a closed end, and in any two adjacent stages of sleeves, the inner diameter of the sleeve close to the first end is smaller than that of the sleeve close to the second end. The length of the sleeve close to the first end is smaller than that of the sleeve close to the second end; the axial length of the multi-stage structure is larger than or equal to 800 mm, the wall thickness of the portion, located at the first end, of the sleeve is smaller than 3 mm, and the temperature measuring element is detachably installed in the multi-stage structure and used for measuring the temperature of the end of the first end. According to the multi-stage structure, the self-weight resistance of the temperature measuring device can be improved, so that when the temperature measuring device is applied to the chemical vapor deposition equipment for temperature measurement, the deviation degree of the first end in the gravity direction can be slowed down, and the temperature measuring accuracy is improved.

Owner:SUZHOU SICREAT NANOTECH CO LTD

Circuit board manufacturing method

ActiveCN112930033BImprove production yieldImprove reliabilityPrinted circuit manufactureEngineeringCopper foil

The invention relates to the field of circuit board manufacturing, and provides a method for manufacturing a circuit board, which comprises the steps of pressing boards, drilling alignment holes, drilling auxiliary holes, copper sinking electroplating, and exposure. In the step of drilling alignment holes, at least three alignment holes are drilled on the periphery of the plate surface of the pressed blank; in the step of drilling auxiliary holes, at least one auxiliary structure is drilled on the periphery of each alignment hole , the auxiliary structure includes a plurality of auxiliary holes arranged in a circular array; in the copper plating step, copper plating is performed on each alignment hole and each auxiliary hole; in the exposure operation step, grab the center of each alignment hole as Align the reference, and then perform exposure treatment on the surface of the copper foil away from the mother board. The circuit board manufacturing method realizes layer-by-layer guarantee and improves the inter-layer alignment accuracy by improving the offset degree of the center of the alignment hole before and after electroplating, and finally improves the inter-layer alignment accuracy of the multilayer circuit board, effectively reducing the alignment deviation, Therefore, the production yield and quality reliability of the multilayer circuit board can be effectively improved.

Owner:KINWONG ELECTRONIC TECH (ZHUHAI) CO LTD

Thin film transistor and its manufacturing method, array substrate, display device

ActiveCN107123687BReduce the degree of impactInjection blockingTransistorSolid-state devicesTarget surfaceDisplay device

Owner:BOE TECH GRP CO LTD +1

A gating device based on niobium oxide and its preparation method

ActiveCN108539014BReduce the degree of offsetImprove electrical stabilityElectrical apparatusEngineeringMaterials science

The invention provides a gating device based on niobium oxide, which comprises a bottom electrode, a conversion layer and a top electrode from bottom to top, the bottom electrode is TiN or conductive glass, the conversion layer is niobium oxide, The top electrode is platinum. In the invention, niobium oxide is used as a conversion layer, TiN or conductive glass is used as a bottom electrode, and metal platinum is used as a top electrode to form a gating device based on niobium oxide with excellent electrical stability. Experimental results show that the gating device provided by the present invention is tested 100 cycles, and the degree of deviation of the obtained curve is small, indicating that it has excellent electrical stability.

Owner:HUBEI UNIV

A target extraction and tracking camera and method for an inter-satellite laser communication pat system

ActiveCN111211838BImprove tracking accuracyReduce off-target delayTelevision system detailsColor television detailsComputer hardwareLight spot

The invention discloses a target extraction and tracking camera and method of an inter-satellite laser communication PAT system. The present invention integrates the three functions of detector driving and data processing, target detection and extraction, and galvanometer control and tracking in both software and hardware, which can reduce the delay of off-target amount, improve the system closed-loop control bandwidth, and further improve the tracking of the PAT system precision. The basic working principle of the camera is: the short-wave infrared detector receives the beacon light from Jingxin, and under the excitation of the analog voltage and the digital timing of the FPGA chip, it completes the detection and output of the Jingxin beacon light. The output signal passes through the amplification circuit and the analog The processing of the digital conversion circuit forms a digital image signal and enters the FPGA chip. The FPGA chip performs a series of processing on the digital image data, such as preprocessing of the digital image data, high-precision light spot extraction, and galvanometer control, and outputs digital quantities to the digital-to-analog converter to generate control voltages, and finally controls the fine-tracking galvanometer to complete high-precision, low-latency Gray beacon tracking.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

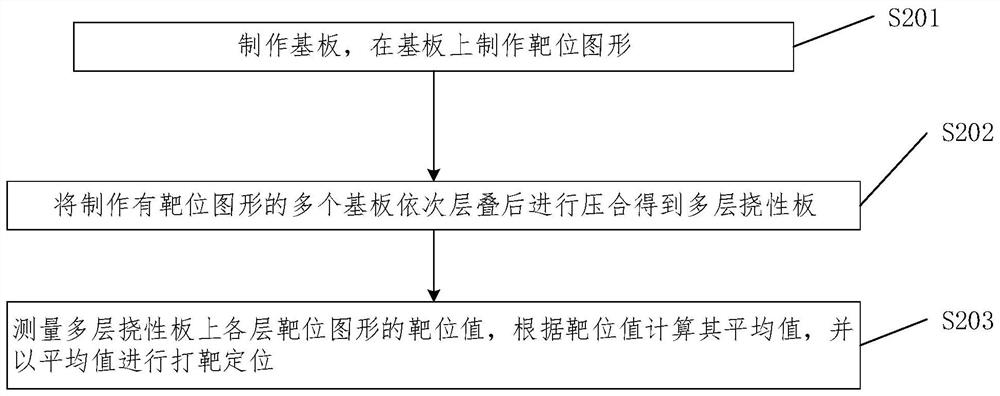

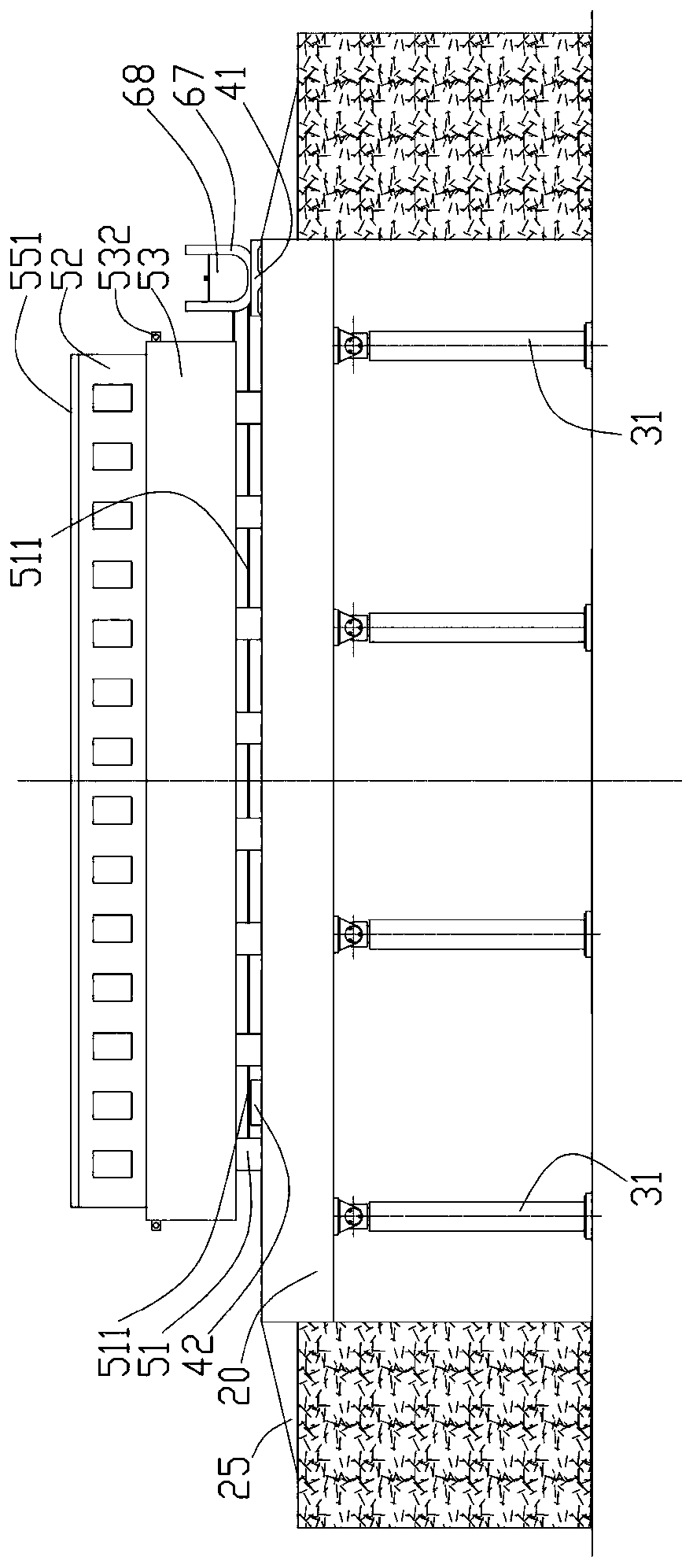

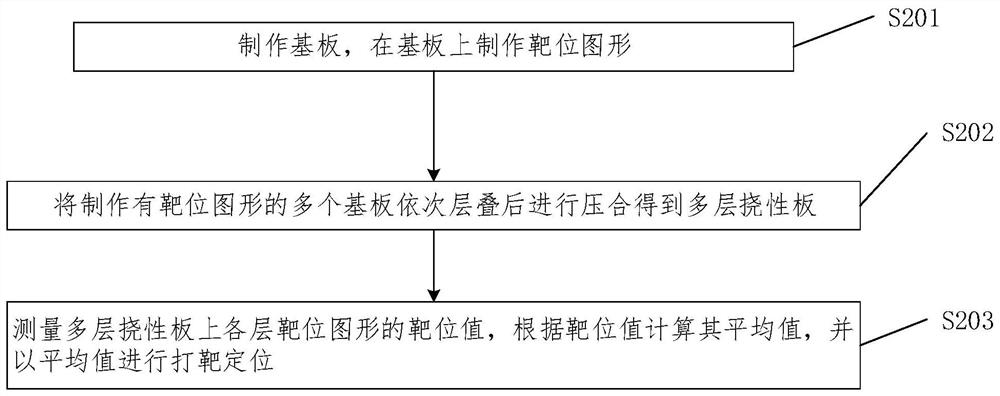

Multi-layer flexible board preparation method for improving alignment accuracy between layers

ActiveCN112839447BIncrease productivityImprove product qualityFlexible printed circuitsCircuit board tools positioningGraphicsProcess engineering

The invention discloses a method for preparing a multi-layer flexible board for improving the alignment accuracy between layers, which comprises manufacturing a substrate and making a target pattern on the substrate; laminating a plurality of substrates with the target pattern sequentially and laminating them to obtain Multi-layer flexible board; measure the target position value of each layer of the target position pattern on the multi-layer flexible board, calculate the average value according to the target position value, and use the average value to perform target positioning. The present invention measures the target position value of each layer of the target position pattern on the multi-layer flexible board after lamination, calculates the average value according to the target position value, and uses the average value to perform target positioning, which can effectively reduce the degree of deviation of each layer, The best positioning is used to ensure the alignment accuracy between layers, which greatly improves the production efficiency and quality of circuit boards, and significantly improves the problem of product scrapping caused by layer-to-layer offset in traditional technology.

Owner:FREEWON CHINA CO LTD

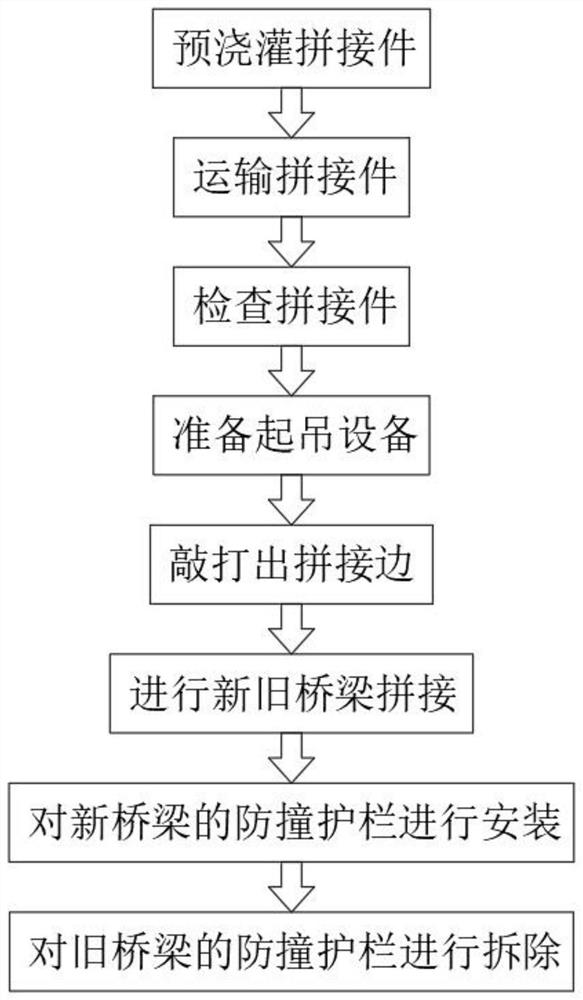

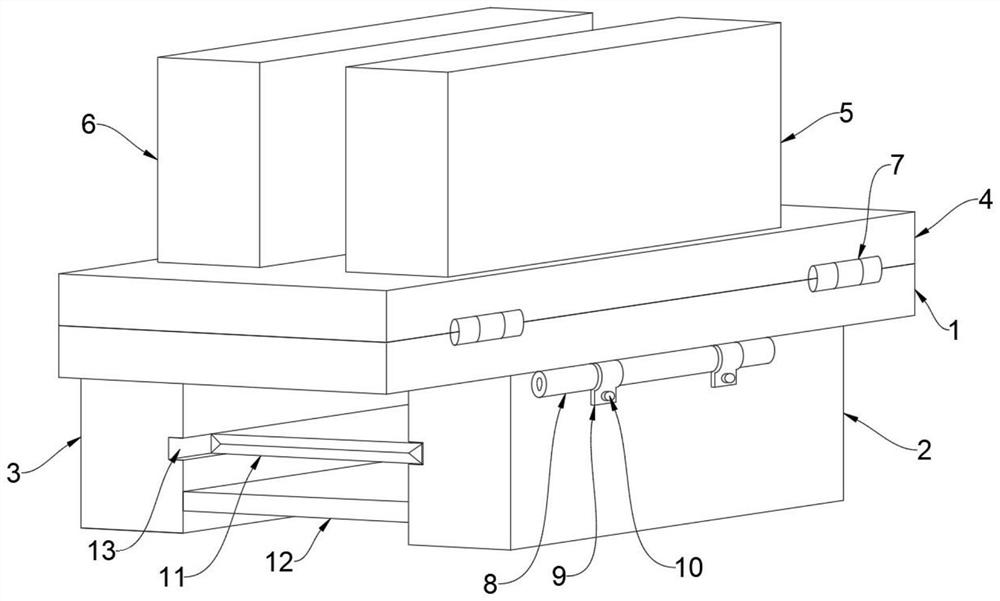

Bridge widening and splicing method

InactiveCN112900289AReduce the degree of offsetEven by forceBridge erection/assemblyBridge strengtheningRebarStructural engineering

The invention discloses a bridge widening and splicing method which comprises the following steps: 1, pre-embedding reinforcing steel bars and pouring required splicing pieces in advance in a factory, cooling and forming the splicing pieces, and storing the splicing pieces indoors; 2, transporting the poured splicing pieces by a plurality of transport vehicles, and transporting the needed splicing pieces to a construction site for standby application; 3, unloading the splicing pieces transported to the construction site one by one, quality inspection is conducted one by one after unloading is completed, whether the splicing pieces meet the construction standard or not is checked, meanwhile, whether the splicing pieces are damaged or not in the transportation process is checked, and registration is performing if the splicing pieces are damaged; and 4, starting to prepare equipment for new and old bridge construction. According to the method, the balance degree of widening of the new and old bridges is considered by means of laser, so that the problems that when the new and old bridges are widened, people need to observe the balance degree by means of eyes, deviation is caused, and the service life is shortened are effectively solved.

Owner:荀敬川

Light emitting device and display panel

PendingCN112599688AIncrease the layer rangeReduce the degree of offsetSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention discloses a light emitting device and a display panel. The light emitting device comprises a first electrode, a second electrode, a light-emitting layer arranged between the first electrode and the second electrode, including a first host material and a guest material, and having a side facing the first electrode and a side facing the second electrode, and an auxiliary light-emittinglayer arranged on at least one side of the light-emitting layer; and the auxiliary light-emitting layer material and the first host material are light-emitting host materials used for light-emittingdevices of the same color. The light emitting efficiency of the light emitting device can be improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Camera module and assembly method thereof

ActiveCN110572542BReduce deformationReduce the degree of offsetTelevision system detailsColor television detailsEngineeringCamera module

The invention discloses a camera module, which comprises a sensor assembly with a circuit board and a lens assembly with a base, the circuit board has a first bonding area on the periphery of the central area, and the bottom surface of the base has a The second bonding area corresponding to the first bonding area, the first bonding area of the circuit board and the second bonding area of the base are fixed together by adhesive bonding; the first bonding area Or the surface energy of the second bonding area increases from the inner edge to the outer edge. The camera module can reduce poor appearance and improve focus accuracy and anti-shake accuracy. The invention also discloses an assembly method of the camera module.

Owner:TRULY OPTO ELECTRONICS

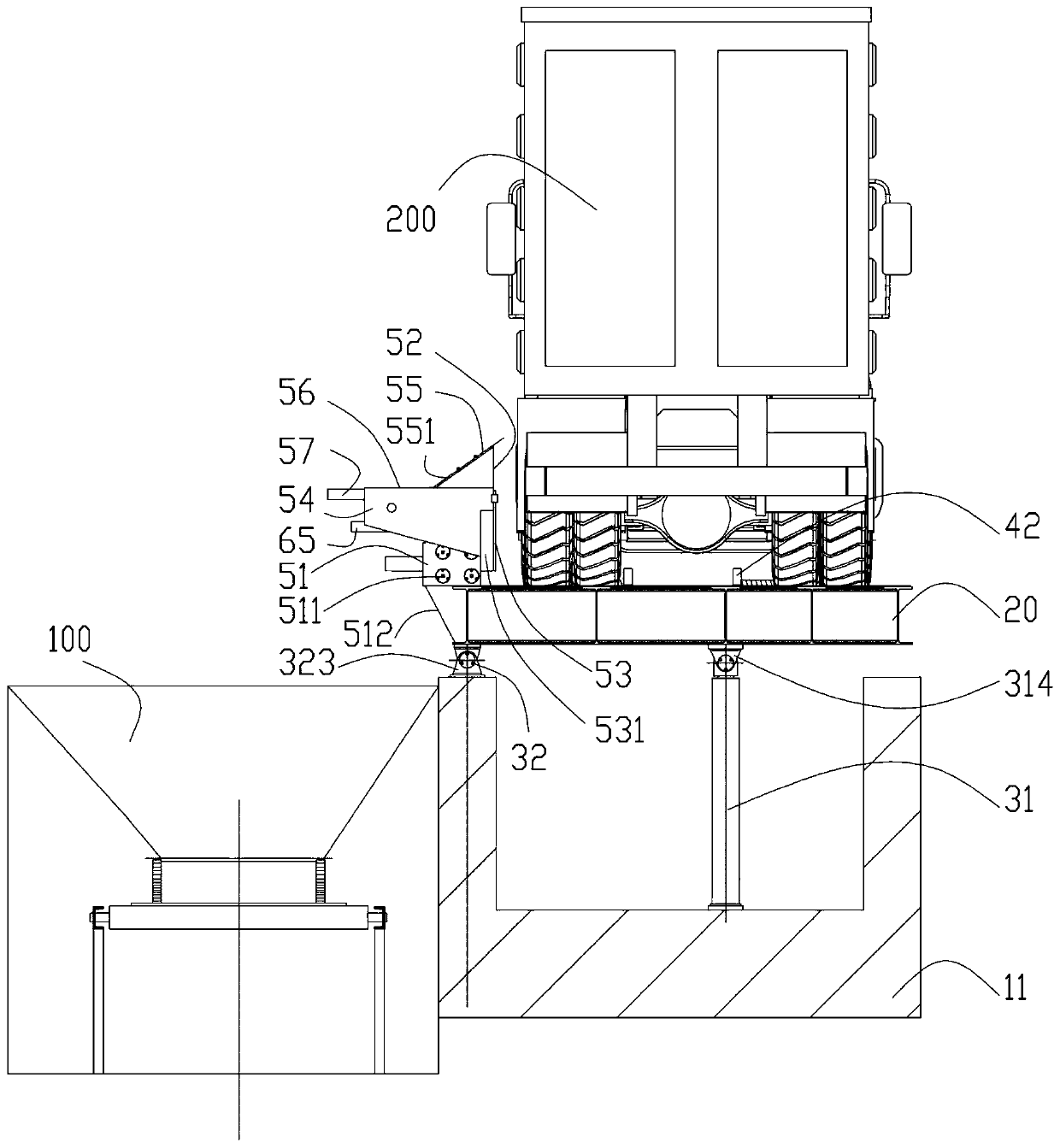

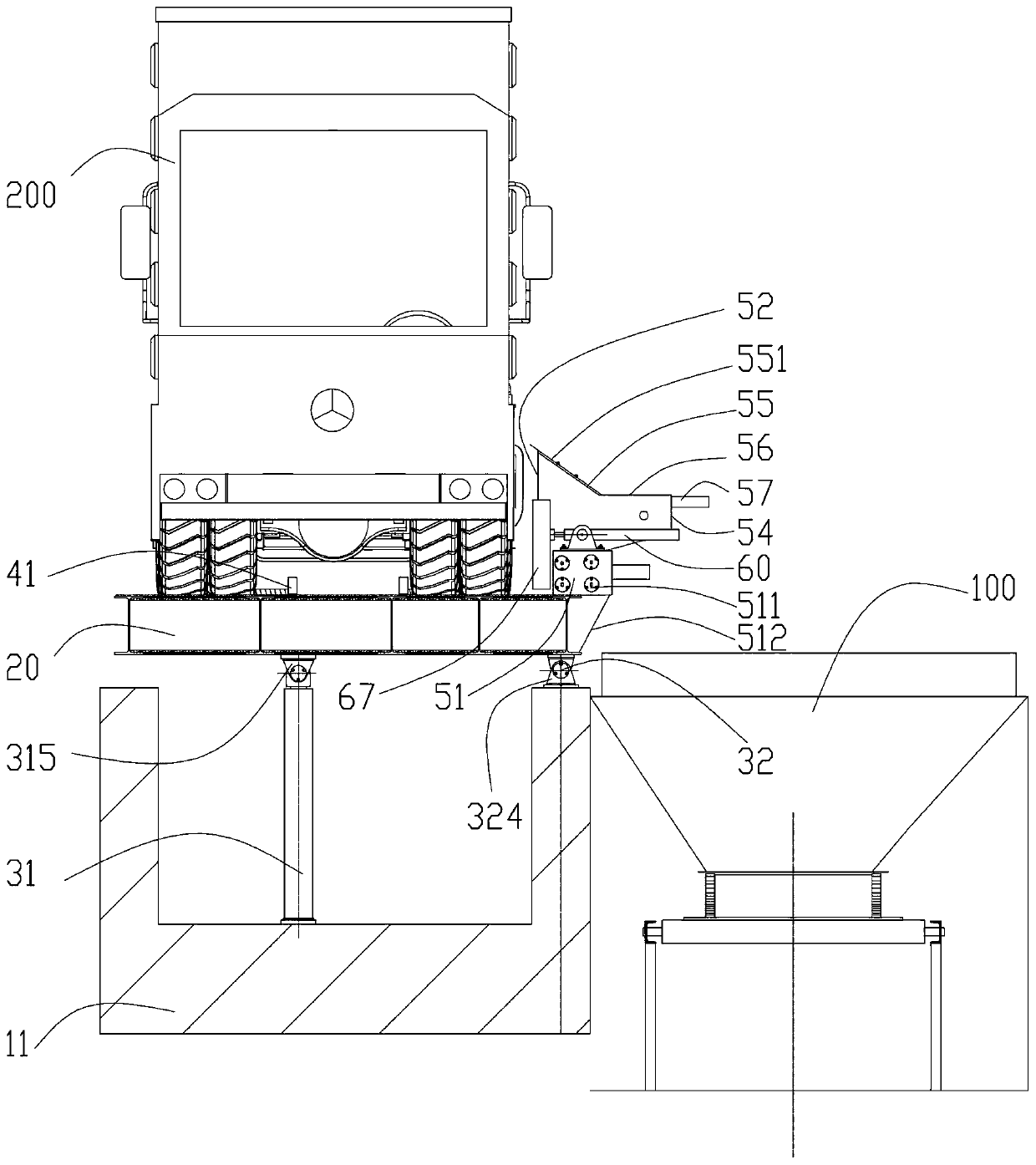

Lateral tilting preventive tipping gear

PendingCN110386482AEvenly share gravityStrong service lifeLoading/unloadingEngineeringMechanical engineering

A lateral tilting preventive tipping gear comprises a supporting mechanism, a bearing mechanism, an inclination angle adjusting mechanism, a positioning mechanism, a feeding mechanism and a hub holding mechanism. According to the scheme, the lateral tilting preventive tipping gear is characterized in that the hub holding mechanism is arranged; a second oil cylinder works, and the output end of thesecond oil cylinder is capable of promoting a U-shaped fixing part to move toward front wheels of a cargo carrying vehicle until the U type fixing part is in close contact with and tightly holds theside surfaces of front wheel tires of the cargo carrying vehicle, and thus continuous and stable thrust is supplied to the front wheel tires; the skew degree of vehicle focus to a feed bin is reduced;the tires at one side of the vehicle is prevented from breaking away from the ground; the vehicle is prevented from lateral tilting; after unloading of the cargo carrying vehicle, the output end of the second oil cylinder is returned to an original position and does not tightly hold the front wheels or rear wheels of the cargo carrying vehicle.

Owner:NINGXIA JIYUAN METALLURGICAL GRP CO LTD +1

Multilayer flexible board preparation method for improving interlayer alignment precision

ActiveCN112839447AIncrease productivityImprove product qualityFlexible printed circuitsCircuit board tools positioningGraphicsEngineering

The invention discloses a multilayer flexible board preparation method for improving interlayer alignment precision. The method comprises the following steps: manufacturing a substrate, and manufacturing a target pattern on the substrate; stacking and then pressing the substrates with the target position patterns in sequence to obtain a multi-layer flexible plate; and measuring target position values of the target position patterns on each layer of the multi-layer flexible plate, calculating an average value according to the target position values, and performing targeting positioning according to the average value. According to the invention, the target position values of the target position patterns on each layer of the multilayer flexible board are measured after lamination, the average value is calculated according to the target position values, and the average value is used for targeting positioning, so that the deviation degree of each layer can be effectively reduced, the interlayer alignment precision is ensured by optimal positioning, the production efficiency and the production quality of the circuit board are greatly improved, and the problem of product scrapping caused by interlayer offset in the traditional technology is obviously improved.

Owner:FREEWON CHINA CO LTD

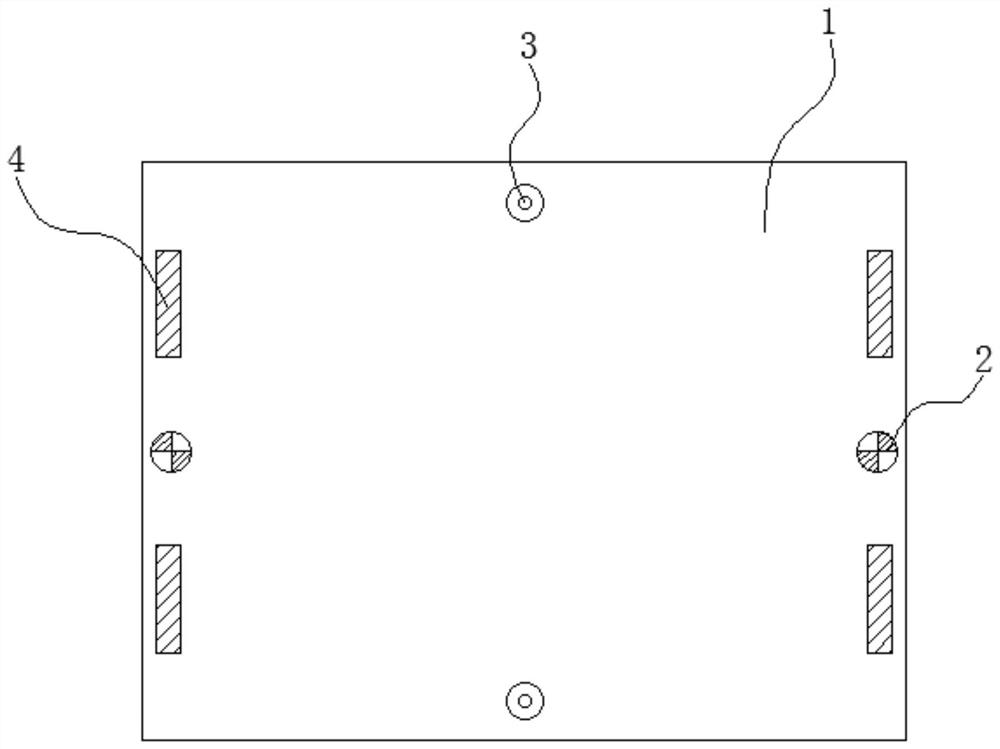

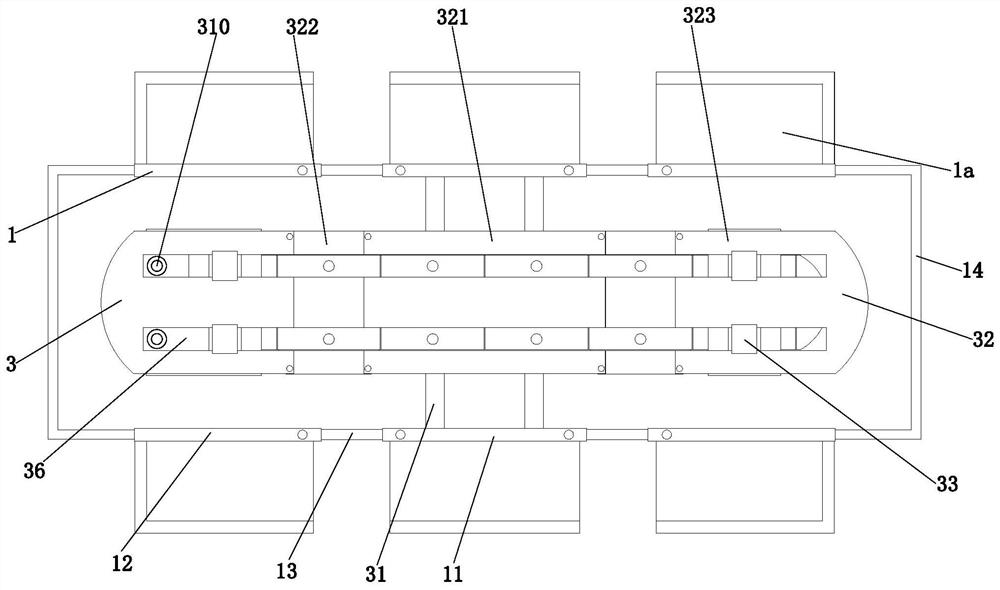

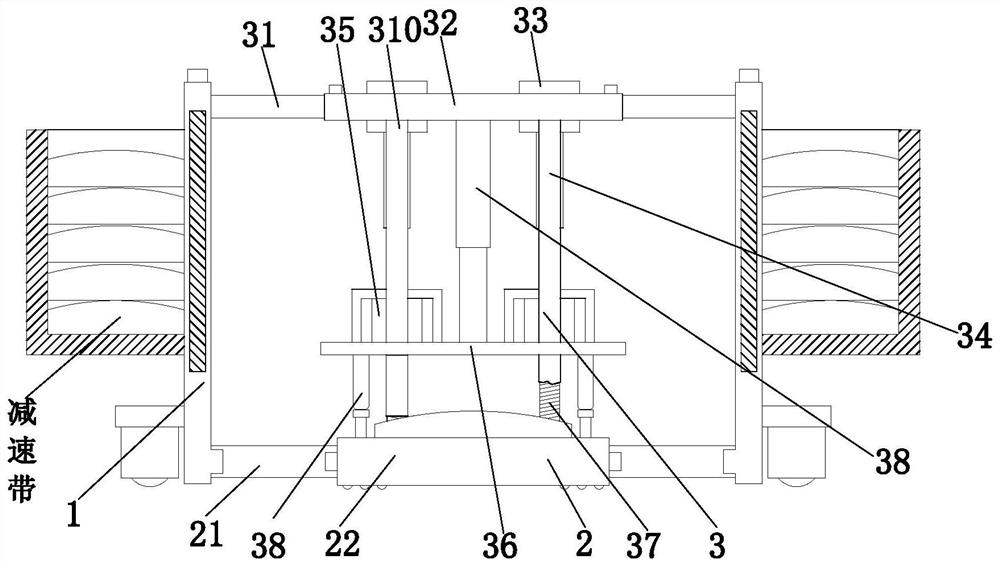

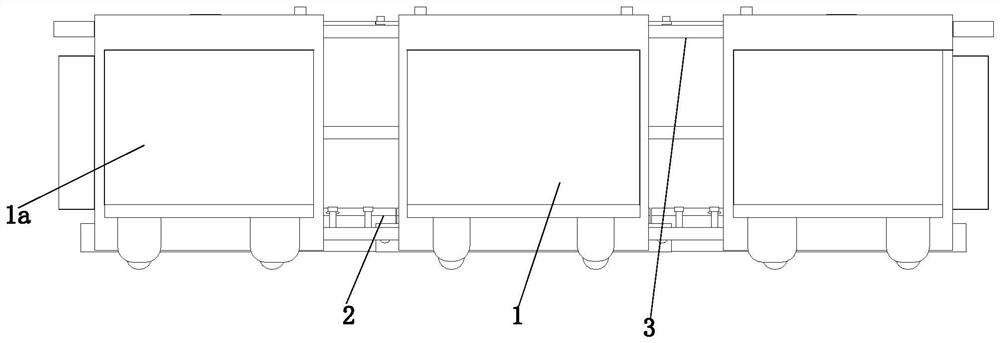

Auxiliary installation device for parking lot gate road deceleration strip

InactiveCN111676854AThe installation position is accurateReduce the degree of offsetDerricks/mastsTraffic signalsSpeed bumpDrill bit

The invention relates to auxiliary installation device for a deceleration strip of a parking lot gate road. The device comprises a moving frame, a positioning device and a mounting auxiliary device, wherein the positioning device is installed on the moving frame, the installation auxiliary device is arranged above the positioning device and installed on the side wall of the moving frame, the walking wheels are arranged at the lower end of the moving frame, and the installation auxiliary device comprises a positioning rod, an installation plate, an electric sliding block, a telescopic rod, a rotating motor, a connecting plate, a drill bit, a lifting air cylinder, an extrusion rod and a nail guide pipe. The deceleration strips to be installed are arranged and fixed in advance through the positioning device; so that compared with a manual hole opening mode, the hole opening auxiliary device has the advantages that the deviation degree of the hole opening position is reduced, the working position does not need to be repeatedly adjusted, and the working quality and the working efficiency are effectively improved.

Owner:武汉雅阁市政建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com