High-voltage lithium cobalt oxide positive electrode active material and preparation method and application thereof

A positive active material and active material technology, applied in the field of high-voltage lithium cobalt oxide positive active material and its preparation, can solve the problems of poor thermal stability and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

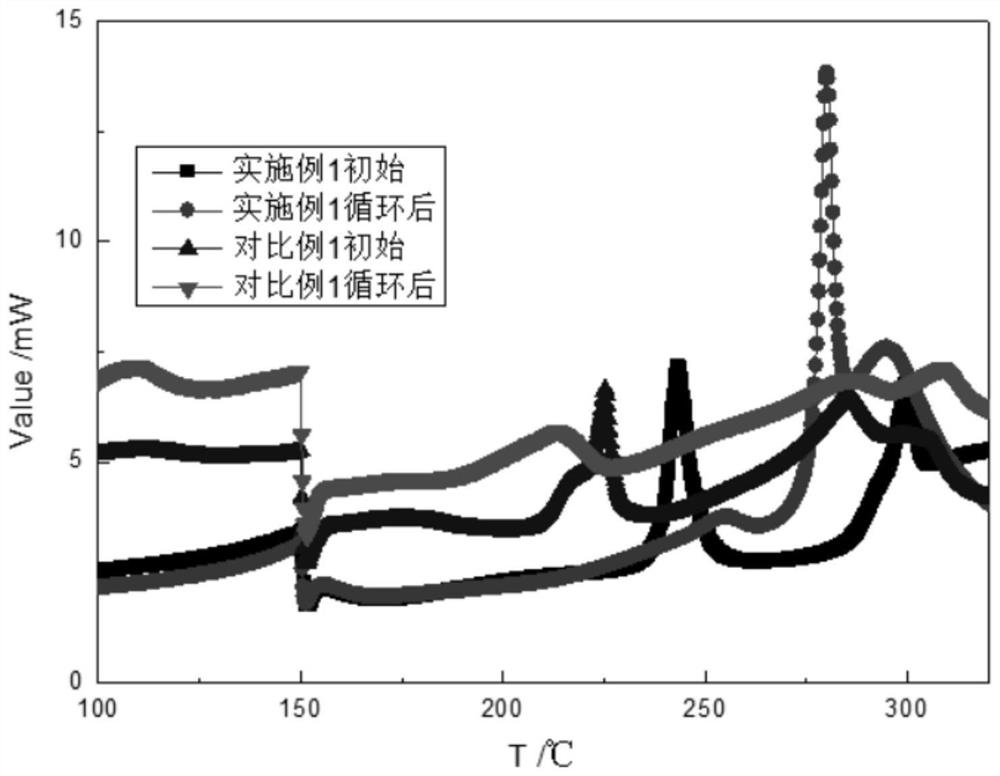

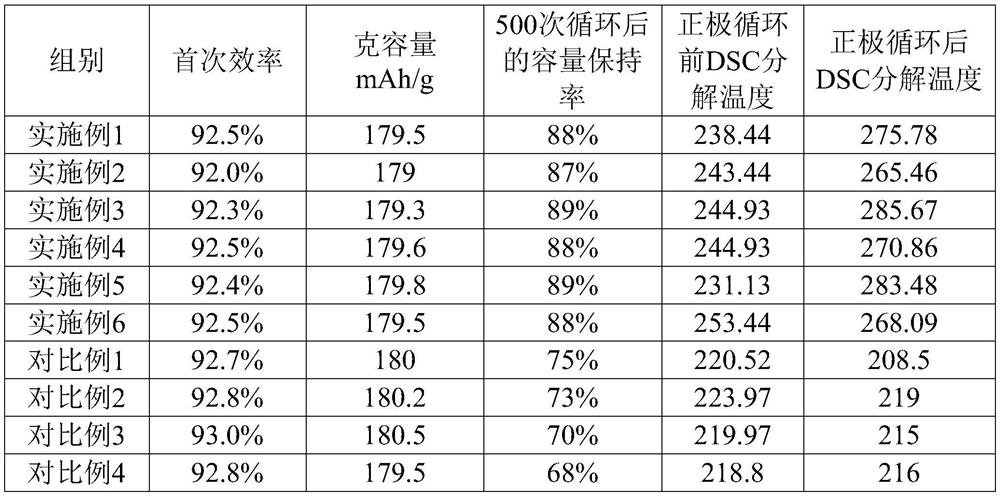

Embodiment 1

[0099] The positive electrode active material has a core-shell structure, including a core material and a shell structure, wherein the core material includes a large particle lithium cobaltate A1 and a small particle lithium cobaltate A2, and the chemical composition of the large particle lithium cobaltate A1 and the small particle lithium cobaltate A2 is uniform. for Li 1.03 co 0.987 Al 0.01 Mg 0.002 Y 0.001 o 2 , where the D of the large particle lithium cobaltate A1 50 17.5μm, D of small particle lithium cobaltate A2 50 The mass ratio of large particle lithium cobaltate A1 to small particle lithium cobaltate A2 is 8:2, and the shell structure is TiO 2 ;

[0100] The preparation method of the positive electrode active material comprises the following steps:

[0101] (1) Dissolve CoSO with deionized water 4 、Al 2 (SO 4 ) 3 , configured as a mixed salt solution with a molar ratio of Co:Al=98.7:1, and the Co in the mixed salt solution 2+ The concentration of the so...

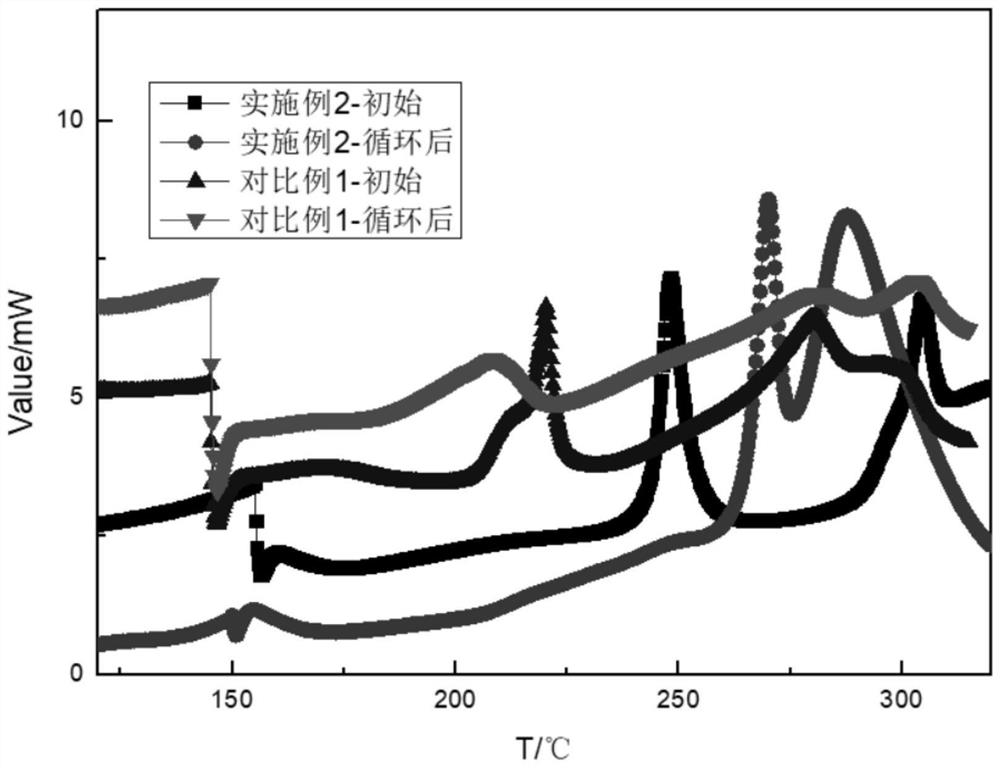

Embodiment 2

[0106] The positive electrode active material has a core-shell structure, including a core material and a shell structure, wherein the core material includes large particles of lithium cobaltate A1 and small particles of lithium cobaltate A2, and the chemical composition of large particles of lithium cobaltate A1 is Li 1.03 co 0.987 Al 0.01 Mg 0.002 Y 0.001 o 2 , D of large particle lithium cobalt oxide A1 50 17.5μm, the chemical composition of small particles of lithium cobaltate A2 is Li 1.03 co 0.965 Al 0.015 Mg 0.02 o 2 , D of small particle lithium cobaltate A2 50 The mass ratio of large particle lithium cobaltate A1 to small particle lithium cobaltate A2 is 8:2, and the shell structure is AlF 3 Wherein, the preparation method of large particle lithium cobaltate A1 is the same as embodiment 1, and the preparation method of small particle lithium cobaltate A2 comprises the steps:

[0107] (1) Dissolve CoSO with deionized water 4 、Al 2 (SO 4 ) 3 , configured ...

Embodiment 3

[0112] Positive electrode active materials include large particle positive electrode active materials and small particle positive electrode active materials. Large particle positive electrode active materials have a core-shell structure, including core materials and shell structures. The core material is large particle lithium cobaltate A1, and its chemical composition is Li 1.03 co 0.987 Al 0.01 Mg 0.002 Y 0.001 o 2 , D of large particle lithium cobalt oxide A1 50 18.5μm, the shell structure is Al 2 o 3 The small particle positive electrode active material has a core-shell structure, including a core material and a shell structure, wherein the core material is a small particle lithium cobaltate A2, and its chemical composition is Li 1.03 co 0.987 Al 0.01 Mg 0.002 Y 0.001 o 2 , D of small particle lithium cobaltate A2 50 5μm, the shell structure is AlF 3 and TiO 2 The mass ratio of large particle positive electrode active material and small particle positive elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com