Cathode active material and preparation method thereof, and application thereof in lithium ion secondary battery

A positive electrode active material and active material technology, applied in high-voltage lithium cobalt oxide positive electrode active material and its preparation, and in the field of lithium-ion secondary batteries, can solve the problem of no longer having intercalation and deintercalation capabilities, and the intensification of side reactions between positive electrode active materials and electrolytes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

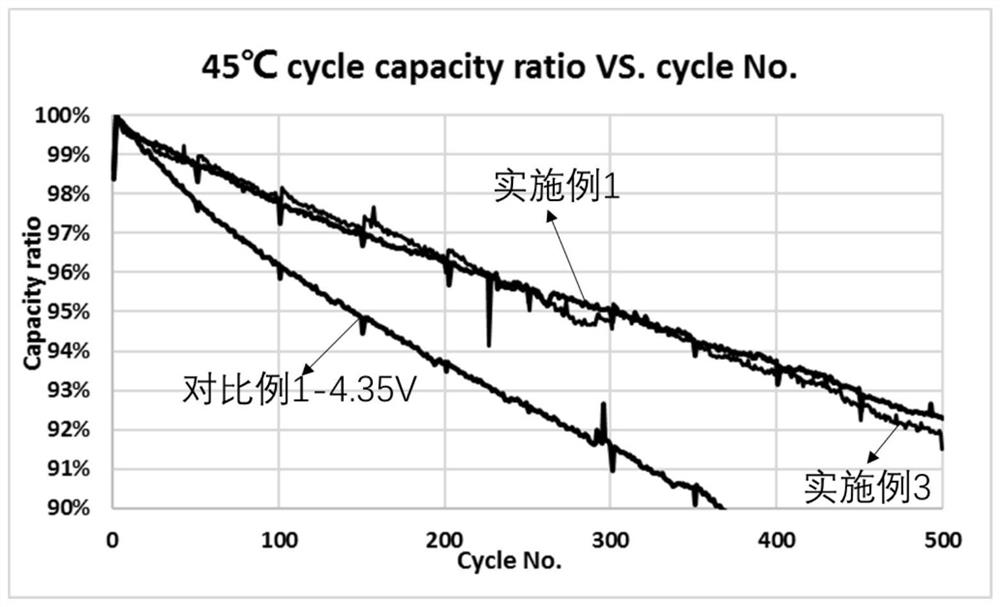

Embodiment 1

[0102] A positive electrode active material with excellent cycle performance under a high-voltage system, the positive electrode active material includes core materials A1, A2 and shell material B1, wherein the shell material B1 is coated on the surface of the core materials A1, A2 to form a core-shell structure particles; the composition of core materials A1 and A2 is LiCo 0.998 al 0.001 Mg 0.0005 Ni 0.0005 o 2 , the particle size D of nuclear material A1 50 5.5 μm, particle size D of core material A2 50 18.0 μm, the mass ratio of core material A1 and core material A2 is 20:80; the shell material B1 is Li 2 MgTiO 4 , the molecular formula of the positive electrode active material is 0.004 Li 2 MgTiO 4 0.996 Li 0.998 al 0.001 Mg 0.0005 Ni 0.0005 o 2 , the formed positive electrode active material can be defined as (A1+A2)×B1.

[0103] The preparation method of the positive electrode active material is as follows:

[0104] (1) CoCl 2 、Al 2 (SO 4 ) 3 , MgSO 4...

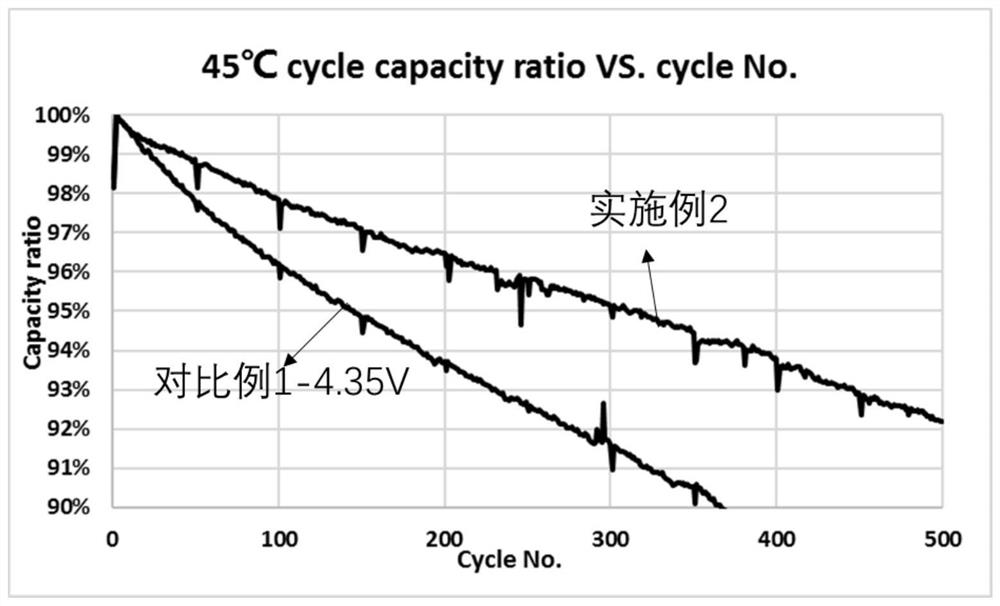

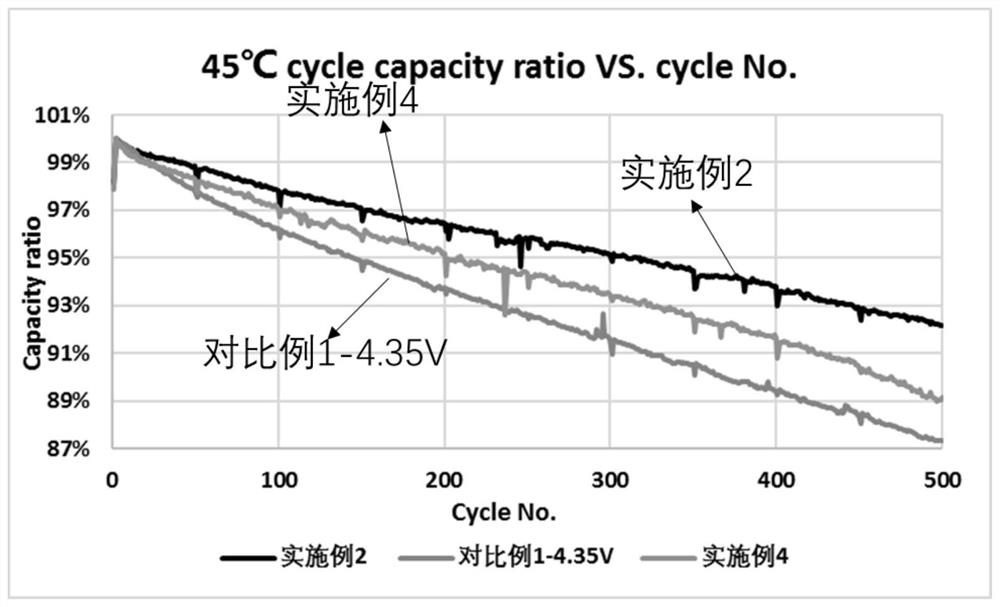

Embodiment 2

[0112] Others are the same as embodiment 1, and the difference is the following steps:

[0113] (1) CoCl 2 、Al 2 (SO 4 ) 3 , MgSO 4 , Nickel acetate is dissolved in water, configured into a solution with a molar ratio of Co:Al:Mg:Ni=99.825:0.1:0.0375:0.0375, and Co doped with Al, Mg, and Ni is prepared. 3 o 4 Precursor.

[0114] (2) Co doped with Al, Mg and Ni prepared above 3 o 4 Precursor, Li 2 CO 3 , MgSO 4 , mixed with nickel acetate, Co:Mg:Ni=0.998:0.00125:0.00125, wherein the molar ratio of Li to Co is 100:99.6, after physically mixing the above substances, place them in a muffle furnace for calcination, and the calcination temperature is 1035°C , the calcination time is 11h, and then the calcined product is pulverized to obtain LiCo with uniform particle distribution. 0.998 al 0.001 Mg 0.0005 Ni 0.0005 o 2 (i.e. the particle size D of nuclear material A1 50 5.5 μm, particle size D of core material A2 50 is 18.0 μm).

[0115] The molecular formula of t...

Embodiment 3

[0118] Others are the same as embodiment 1, and the difference is the following steps:

[0119] (1) CoCl 2 Dissolved in aqueous solution to prepare Co with uniform particle distribution 3 o 4 Precursor;

[0120] (2) Co prepared above 3 o 4 Precursor, Li 2 CO 3 、Al 2 (SO 4 ) 3 , MgSO 4 , nickel acetate mixed, wherein Co:Al:Mg:Ni=0.998:0.001:0.0005:0.0005, the molar ratio of Li and Co is 100:99.6, after the above-mentioned substances are physically mixed, placed in a muffle furnace for calcining, calcining The temperature is 1035°C, the calcination time is 11h, and then the calcined product is pulverized to obtain LiCo with uniform particle distribution. 0.998 al 0.001 Mg 0.0005 Ni 0.0005 o 2 (i.e. the particle size D of nuclear material A1 50 5.5 μm, particle size D of core material A2 50 is 18.0 μm).

[0121] The molecular formula of the positive electrode active material is:

[0122] 0.004Li 2 MgTiO 4 0.996 LiCo 0.998 al 0.001 Mg0.0005 Ni 0.0005 o 2 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com