Camera module and assembly method thereof

The technology of a camera module and assembly method, which is applied in the field of photography, can solve the problems affecting the focusing accuracy and anti-shake accuracy of the camera module, and affecting the appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

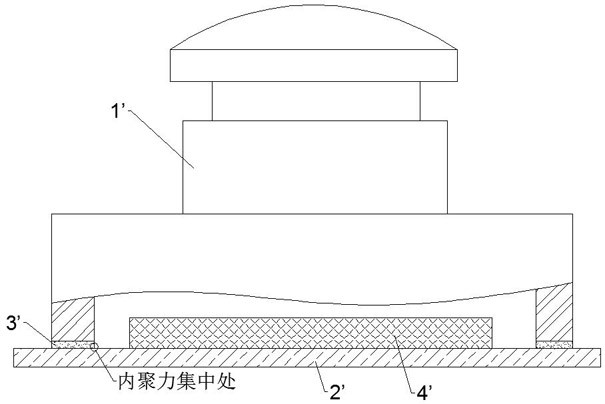

Problems solved by technology

Method used

Image

Examples

Embodiment 1

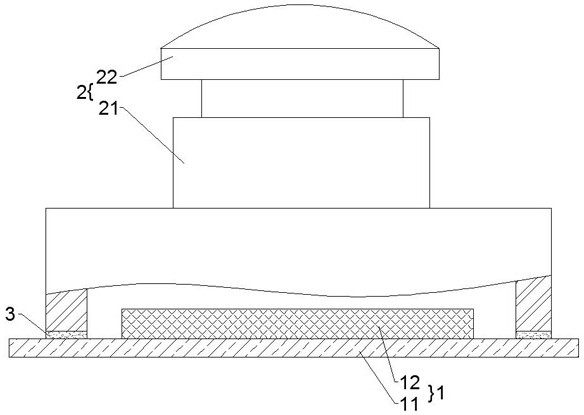

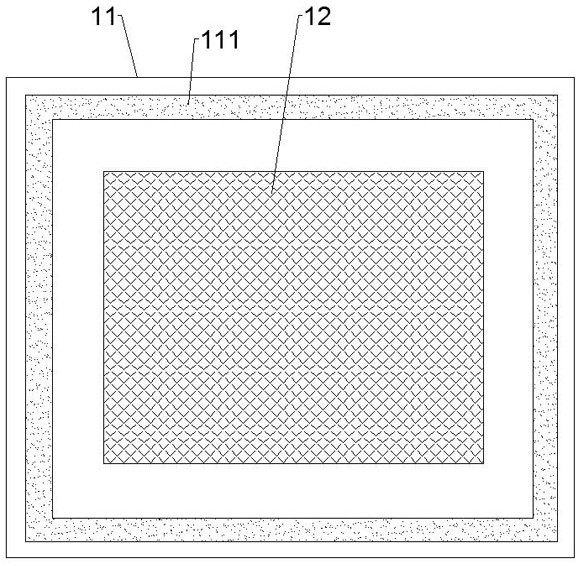

[0027] Such as Figure 2-4 As shown, a camera module includes a sensor assembly 1 and a lens assembly 2. The sensor assembly 1 includes a circuit board 11 and an image sensor 12 mounted on the central area of the circuit board 11. The lens assembly 2 includes a base 21 and an optical lens 22 mounted in the base 21; the circuit board 11 has a first bonding area 111 on the periphery of the central area, and the bottom surface of the base 21 has a first bonding area 111; The second adhesive area 211 corresponding to the area 111, the first adhesive area 111 of the circuit board 11 and the second adhesive area 211 of the base 21 are fixed together by adhesive 3; the first adhesive The surface energy of the bonding area 111 or the second bonding area 211 increases from the inner edge to the outer edge.

[0028] Surface energy refers to the measure of the breaking of chemical bonds between molecules to create the surface of matter. The higher the surface energy of a substance, t...

Embodiment 2

[0034] Such as Figure 5 As shown, an assembly method of a camera module includes:

[0035] Step 1: If Figure 2-4 As shown, a sensor assembly 1 and a lens assembly 2 are provided. The sensor assembly 1 includes a circuit board 11 and an image sensor 12 mounted on the central area of the circuit board 11. The lens assembly 2 includes a base 21 and a The optical lens 22 in the base 21; the periphery of the central area of the circuit board 11 has a first bonding area 111, and the bottom surface of the base 21 has a second bonding area 111 corresponding to the first bonding area 111; The bonding area 211, the surface energy of the first bonding area 111 or the second bonding area 211 increases gradually from the inner edge to the outer edge;

[0036] Step 2: bonding and fixing the first bonding area 111 of the circuit board 11 and the second bonding area 211 of the base 21 together through glue 3 .

[0037] Among them, before step 1, it also includes:

[0038] The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com