Temperature measuring device and chemical vapor deposition equipment

A technology of temperature measuring device and temperature measuring element, which is applied in the direction of measuring device, gaseous chemical plating, thermometer, etc., can solve the problems of affecting the vapor deposition process and yield, inaccurate temperature measurement results, and short life of temperature measuring elements, etc. Improve the effect of anti-self-weight, not easy to bend, and low cost of preparation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

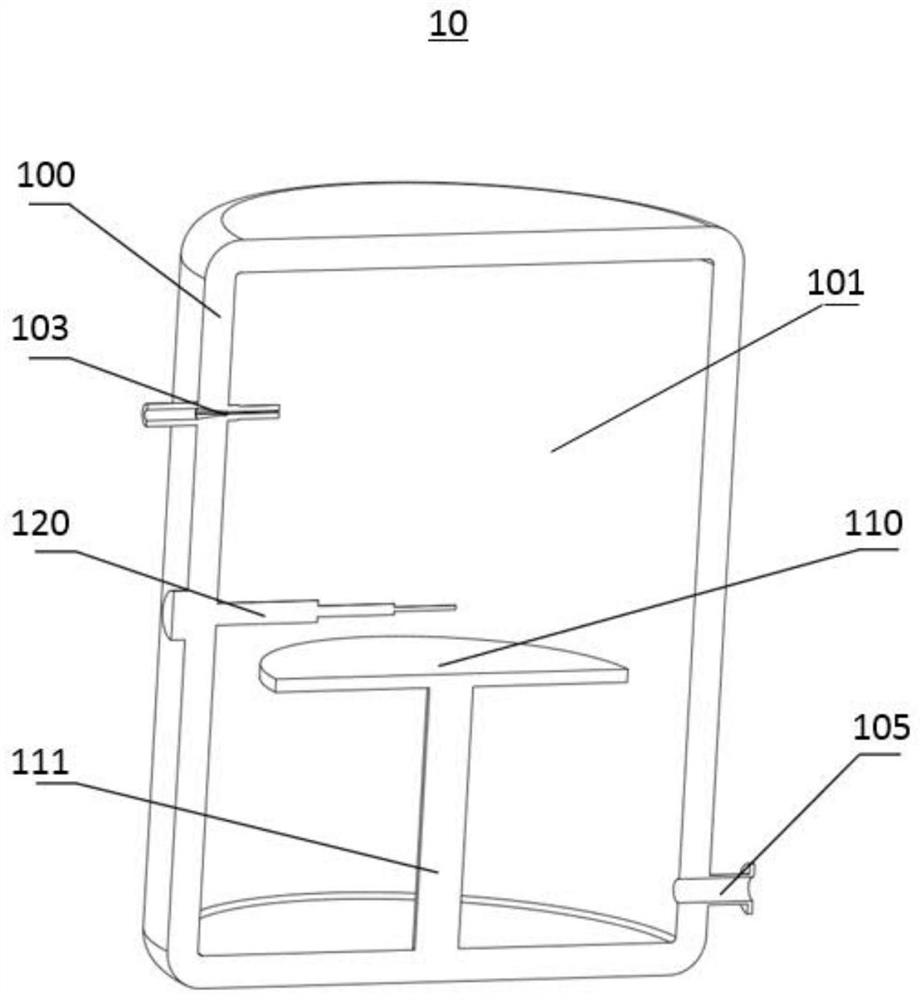

[0052] see figure 1 , a chemical vapor deposition equipment 10 , which mainly includes a furnace body 100 , a stage 110 and a temperature measuring device 120 .

[0053] The furnace body 100 has a furnace cavity 101, and precursors and other reaction gases are reacted and deposited in the furnace cavity 101, wherein the furnace body 100 is provided with an air inlet 103 and an exhaust port 105 communicating with the furnace cavity 101, and the air inlet 103 is used for The mixed gas containing the precursors and other reaction gases is transported into the furnace cavity 101, and the exhaust port 105 is used to discharge the mixed substances of the unreacted precursors and gases, reaction products and other by-products from the furnace cavity 101, so that After new precursors and other reaction gases enter the furnace cavity 101 , the position of the exhaust port 105 is lower than the horizontal plane where the intake port 103 is located.

[0054] Generally, the cross section...

Embodiment 2

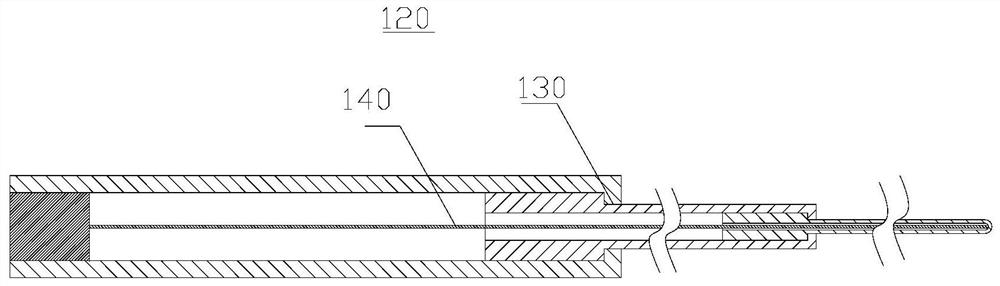

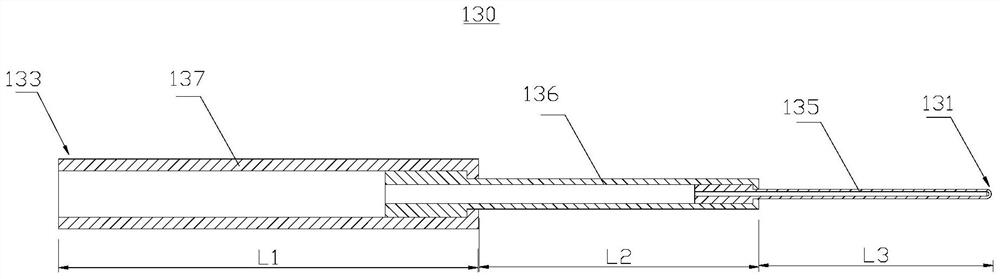

[0087] see figure 2 as well as image 3 , the temperature measurement device 120 provided in this embodiment includes a multi-level structure 130 and a temperature measurement element 140 installed in the multi-level structure 130 .

[0088] The multi-stage structure 130 is a three-stage sleeve, and the multi-stage structure 130 has a first sleeve 135 , a second sleeve 136 and a third sleeve 137 which are detachably connected along the axial direction from the first end 131 to the second end 133 . The inner diameter of the first sleeve 135 is 4mm, the wall thickness is 2mm, the length is 200mm, and the material is graphite; the inner diameter of the second sleeve 136 is 16mm, the wall thickness is 5mm, the length is 240mm, and the material is graphite; the third sleeve 137 The inner diameter is 40mm, the wall thickness is 10mm, the length is 360mm, and the material is graphite.

[0089] The temperature measuring element 140 is a thermocouple, and the temperature measuring e...

Embodiment 3

[0091] see figure 2 as well as image 3 , the temperature measurement device 120 provided in this embodiment includes a multi-level structure 130 and a temperature measurement element 140 installed in the multi-level structure 130 .

[0092] The multi-stage structure 130 is a three-stage sleeve, and the multi-stage structure 130 has a first sleeve 135 , a second sleeve 136 and a third sleeve 137 which are detachably connected along the axial direction from the first end 131 to the second end 133 . The inner diameter of the first sleeve 135 is 4mm, the wall thickness is 2mm, the length is 200mm, and the material is silicon carbide; the inner diameter of the second sleeve 136 is 16mm, the wall thickness is 5mm, the length is 240mm, and the material is graphite; the third sleeve The inner diameter of 137 is 40mm, the wall thickness is 10mm, the length is 360mm, and the material is graphite.

[0093] The temperature measuring element 140 is a thermocouple, and the temperature m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com